Silvus Technologies demonstrated its MIMO radio repeater capability integrated into QinetiQs TALON and iRobots FasTac robots at the Army Expeditionary Warfighters Experiment (AEWE) Spiral G. TARDECs Ground Vehicle Robotics group requested Silvus to integrate its SC3500 MIMO radio into both robotic platforms as part of TARDECs ISR Mission Concepts platform.

Contributed by | Silvus Technologies

The Silvus SC3500 dual band MIMO radio is a mobile ad-hoc mesh network IP based packet transceiver that delivers cutting edge technology and superior video/command/control data to the operator. It can scale to dozens of nodes in a network and provide an aggregate throughput in excess of 10 Mbps.

The SC3500 integrates easily into both systems using the QinetiQ IP conversion kit for the TALON and a Silvus Integration Kit for Packbots, allowing for a quick bolt-on conversion and operation in a mesh network or repeater configuration. 3 dBi omni antennas were used on all radios with 1 Watt total TX power. The soldiers were instructed not to worry about antenna placement.

The repeater setup was tested in a variety of training missions conducted by the U.S. Army infantry. Some of the missions conducted were:

- Reconnaissance / Surveillance into urban terrain

- Forward Operating Base security

- Defense of urban stronghold

Silvus SC3500 integrated into FasTac & TALON, note the Silvus radio on the ground with the soldiers

Results

The Silvus radios extended the range over existing comms systems used in robots. When applied to infantry missions, it provided them with advanced reconnaissance and surveillance capabilities of their objective from safe standoff distances taking them out of harms way. Using a repeater setup provided:

- 500 meters NLOS range in variable field terrain such as rolling hills and vegetation

- 500 meters NLOS into urban centers

- No need for directional antennas, soldiers focused on missions, not antenna setup

- Either robot could be used as repeater at any time

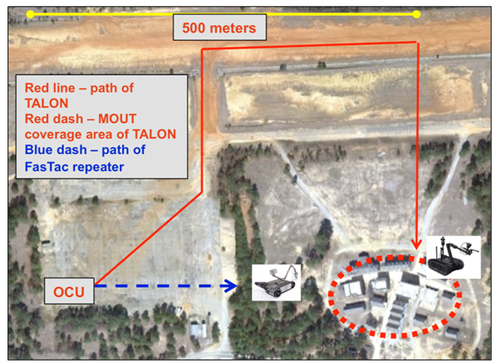

Silvus repeater setup: FasTac in treeline while TALON maintains coverage through entire urban area

Warfighter Review

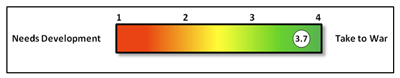

U.S. ATEC (Army Test and Evaluation Command) polled infantry soldiers polled using Silvus’ MIMO radios who feel the SC3500 is ready for war. They determined a user ‘take to war’ score of 3.7 out of 4.

About Silvus Technologies

About Silvus Technologies

Founded in 2004, Silvus is an innovative company focused on advanced cost effective multi-antenna "MIMO" radio solutions for the commercial and military markets. Silvus is also a leader in carrying out state of the art R&D for next generation wireless communications.

Silvus is at the forefront of delivering MIMO based solutions to the military and first responder communities. Silvus has been the sole performer on the multimillion, multi-year Defense Advanced Research Projects Agency's Mobile Networked MIMO (MNM) program. Other government sponsored work has focused on specific applications of MIMO technology to robotic systems, air to ground applications and wireless video. Silvus holds the distinction of being the only communications company working under the JGRE-RTC (Robotics Technology Consortium) program to deliver improved radio links for telerobotic EOD missions.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product