By robotically automating one or more elements of the assembly or packaging line, manufacturers can increase productivity and OEE (overall equipment effectiveness) while enjoying a low total cost of operation (TCO) and quick return on investment (ROI).

Kim Norris | ESS Technologies

Companies in all industries seek ways to increase their “Sustainability Advantage” as today’s eco-aware consumers more often base their purchasing decisions on considerations such as a company’s efforts to reduce their carbon footprint, incorporate re-usable or recyclable packaging and increase the use of renewable energy sources. Any sustainability initiative should include the evaluation of a production line’s overall equipment effectiveness or OEE, which describes, as a percentage, the performance, availability, and quality of a machine, a production line or an entire production plant. Growing competition in the pharmaceutical and medical device markets has caused manufacturers to rethink their assembly and packaging processes to reduce cost, increase productivity and increase OEE. Many manufacturers have turned to robotics integration to accomplish these goals. Robots have experienced considerable cost reduction in the recent past, and they provide high speed efficiency and manual dexterity for machine loading and unloading, product collation, product assembly, product packaging, case packing and palletizing. By robotically automating one or more elements of the assembly or packaging line, manufacturers can increase productivity and OEE while enjoying a low total cost of operation (TCO) and quick return on investment (ROI).

Turnkey Robotic Integration

The right turnkey robotic system integrator can assure the success of automating a packaging line. Manufacturers should work with an integrator who has a thorough understanding of the pharmaceutical and medical device markets and the types of packaging equipment most commonly used in these industries. Ideally, the system integrator would also provide some components of the line and have strong business relationships with their suppliers. This gives the system integrator the expertise and experience to oversee the complete planning, manufacturing, integration and setup of new packaging and assembly lines. They can also offer full turnkey service for upgrading existing lines.

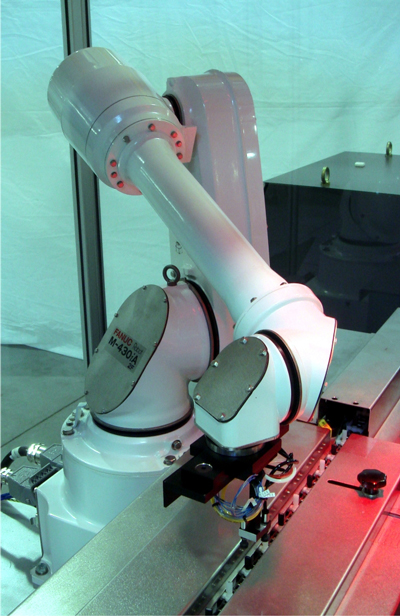

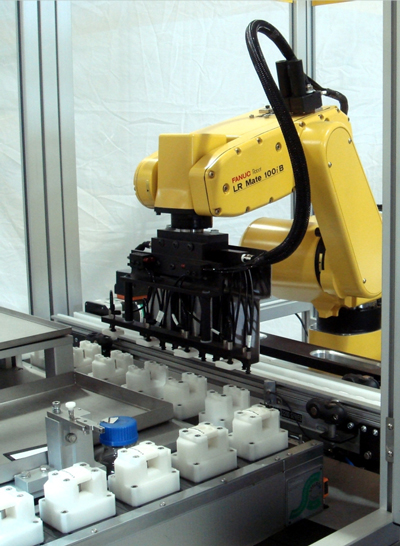

FANUC M-430i Robot Unloading Diagnostic Test Kits onto a Moving Conveyor Infeed on a Thermoform Blister Packing Machine

Once a robotic system integrator has been selected, the integrator should audit the line in order to identify the areas where automation will improve overall OEE and the flow of the manufacturing or packaging process. Automation through robotics integration offers many advantages. Below are eleven ways pharmaceutical companies and medical device manufactures can increase OEE and productivity by automating pharmaceutical and medical device production lines.

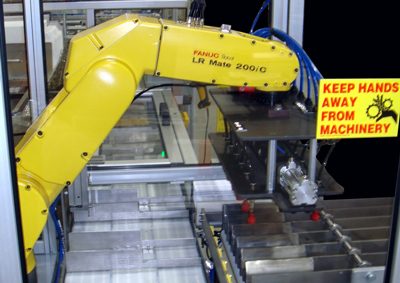

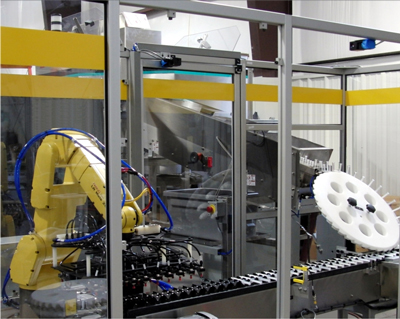

FANUC LR Mate 200i Collating Blister Packs at a Cartoner Infeed

1) Increase efficiency throughout the production or packaging line.

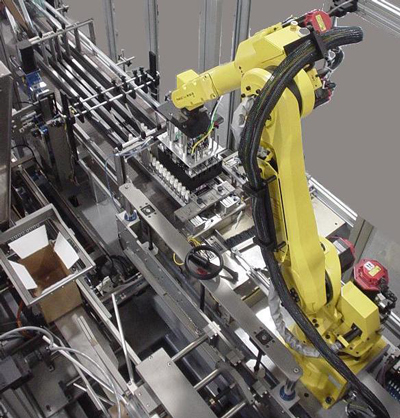

Integrated robotics increase production efficiency at the beginning of a production line, throughout the production process, and at the secondary packaging station where the product is packed in cases and palletized. At the beginning of the line, robots can be used to load products into pucks, onto conveyors, into infeed buckets, and/or into filling equipment, such as cartoners or thermoform blister packing machines. Robotic loading increases speed and efficiency and allows valuable human resources to be redeployed to more demanding parts of the process. Robots can be used to move the product from one station of the process to the next, to streamline production flow. At the end of the line, robots are ideal for packing and palletizing cases. Robotic case packing and palletizing/depalletizing systems offer a smaller footprint and greater precision than conventional case packers, allowing these systems to address end-of-line needs for flexibility and versatility.

2) Increase line flexibility by allowing new products to run on existing lines.

New product introductions and product acquisitions require manufacturers to combine new products with existing products on existing lines. This process often reduces the overall productivity of a line by increasing changeover time and reducing OEE. Integrated robotics simplify the challenge of running new products on an existing line while maintaining efficiency and productivity and dealing with additional changeovers. In most cases, new end-of-arm-tooling and programming are all that is required to run a new product on an existing robotic cell. A thorough system audit, performed by a qualified system integrator is the best way to define these challenges and create a successful solution.

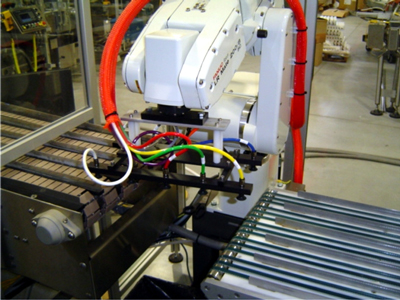

Custom Robot End-of-Arm-Tooling with Very Fast Changeover (less than two minutes)

3) Minimize downtimes between production runs with quick-change custom robotic end-of-arm tooling.

Not many years ago, product changeover could take 2-3 hours per machine. Today’s modern equipment has cut that time to only 15-20 minutes typically. But robotic end effecters in case packing, palletizing and product loading applications can change over in a minute or less. By incorporating quick release pneumatic connections and thumbscrews, a robotic end effecter can be removed and replaced with a new end effecter to handle a different product in only a couple of minutes. This has significant advantages in packaging lines that use shorter runs for independent SKUs.

Integrated Vision for Inspection of Diagnostic Test Kits

4) Reduce waste by automating product loading, handling, and package inspection.

Misfeeds, incomplete loading, and empty container feeding represent the largest sources of waste in the production of pharmaceuticals and medical devices. Currently, about 85% of the horizontal form-fill-seal and blister machines used to package pharmaceutical products and medical devices are manually fed, a process that requires continuous speed and repeatable dexterity on the part of the employees. Employees may also be required to inspect the products and/or place them in the thermoformed tray or blister. Integrated robotics equipped with line tracking and vision provide an ideal solution for these applications. Multi-axis robots can load multiple items in several stations at the same time via electronic line tracking to maintain continuity with the packaging machine. Integrated vision can verify product placement and product quality, while closely monitoring productivity.

5) Enhance the accuracy of multi-item feeds for pouching and kitting applications.

Today’s robotic end effecters offer more agility and dexterity than ever before, allowing them to be used in applications where multiple products are collated and placed together in some sort of package. Integrated vision and inspection routines may be programmed into the robot to allow it to correctly select and collate items of varying sizes entering the packing area on multiple lanes, even on moving conveyors. Vision can also be incorporated into a rejection system that kicks out any incomplete kits, increasing product safety and reducing the waste associated with high product rejection rates.

FANUC Model M-710iC Robot Pallet Cell With Integrated Stretch Wrapper

6) Maximize valuable human resources.

Automated lines allow pharmaceutical and medical device manufacturers to utilize trained personnel in areas of the production process unsuited to automation. By integrating robots, packagers can increase productivity without increasing personnel, reducing labor costs for the assembly and/or packaging process. In areas of the country where the need for human workers is greater than the number of qualified candidates, robots offer a means to meet production demands.

7) Reduce personal injury to workers by eliminating repetitive motion.

Repetitive motion can result in carpal tunnel syndrome, a long term injury caused by the compression of the median nerve in the wrist. This causes numbness, pain, burning, and weakened grip strength. According to the National Institute of Neurological Disorders and Stroke (www.ninds.nih.gov), carpal tunnel syndrome is three times more common among assembly line workers than data entry personnel. The average lifetime cost of carpal tunnel syndrome, including medical bills and lost time from work can exceed $30,000 for each injured worker. Robots cannot be injured by repetitive motion, and they suffer no loss of work due to illness.

Robotic Syringe Loading System

8) Meet the special handling requirements of pharmaceuticals and medical devices.

The Food and Drug Administration (FDA) closely regulates the manufacture of pharmaceuticals and medical devices. Integrated robotics allow manufactures to meet a number of compliance issues, including requirements for pedigree traceability, ergonomics, handling toxic materials, maintaining an aseptic environment, data acquisition and tracking. Robots are ideally suited to capturing process data, providing a clear audit trail to verify FDA compliance. Robots placed in aseptic “clean rooms” allow the manufacturer to protect employees from exposure to hazardous and toxic materials, reduce the cost of protective gear, and reduce the space required. Aseptic clean rooms also protect the product from accidental contamination by workers.

9) Reduce or even eliminate machinery downtime.

Machinery downtime equals loss of productivity and reduced profitability. In calculations for OEE, this parameter can also have the greatest detrimental impact on a line’s effectiveness. This is most true when the machine stops operating if it detects that it has no product to handle at the infeed or if too much product has accumulated at the discharge. By incorporating robotic product loaders or unloaders to the line, the machinery can be run continuously 24-7-365.

10) Simplify process control documentation.

Robots with vision systems can capture part dimensions in real time and save the information using a PC-based controller. This reduces the time needed to document the process control and increases the accuracy of the documentation. As previously mentioned, this is extremely helpful for maintaining FDA audit trails for the production process.

FANUC M-16iC Robot in a Vertical Case Packer Application

11) Reduce damage to goods during the process.

Expensive and fragile items are especially vulnerable to mishandling. Dropped product, bent or broken product, and product contaminated by organic adulterants add cost and reduce productivity. With precise robotic handling, these damages can be reduced or entirely eliminated, increasing cost efficacy and productivity.

Conclusion

Conclusion

Automated production and packaging lines increase productivity and OEE while allowing companies to better utilize valuable human resources. These factors lead to an increased sustainability for the manufacturer by reducing their waste stream, protecting their employees, increasing line productivity, maintaining a low TCO and high ROI. By selecting an experienced system integrator, companies can save time and money while investing in a highly efficient system for manufacturing and packaging pharmaceuticals and medical devices.

About ESS Technologies

ESS Technologies, Inc. specializes in packaging line design, equipment manufacturing, and system integration. Products include: Monoblock fillers/cappers, automatic cartoners, robotic case packers, integrated FANUC robotic systems, robotic palletizers, and custom packaging equipment.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product