Maximizing ROI for Mobile Robots: A Systems Strategy

Mobile robots are more than mere devices; they embody intelligence, communication capabilities, and mobility. The primary function is to transport goods, but it operates within the broader context of a business strategy.

A Cut Above: Adding Next-level Protection for Next-generation Welding

By partnering with Roboworld since their first Cobot rolled off the line on Day 1, all of Vectis' robotic welding systems and teach pendants have included Robosuits® and Pendant Armor®.

Are Labeling and Palletizing Robots the Secret Weapon Manufacturers Need?

Robots are not magic fixes to all manufacturing industry obstacles, but they can allow users to overcome many challenges when implemented thoughtfully.

Amazon announces over €700 million investment in robotics and AI powered technologies across Europe

Amazon is using its Innovation Lab, home to a diverse team of scientists and engineers from all over the world, to develop and test new technologies to better support employees and deliver for customers.

Productivity Inc. Wants Your Robot to Do More

Using ATI's QC-11 Tool Changer and RCT-151 Radially-Compliant Deburring Tool along with a Renishaw probe, they produced a demonstration highlighting their expertise in aiding potential customers to maximize productivity of the robots already installed in their facilities

Shibaura Machine to unveil new SCARA features at Automate 2024

Visitors will be able to see the two newest models in the THE range, the THE800 and THE1000, in action at the show at its booth managed by TM Robotics, its distribution partner in North, Central and South America,.

Fostering Innovation: The Keys to Success

In a world that's always evolving, innovation is how we keep up, grow, and thrive. So, when we talk about nurturing innovation, we're really talking about fuelling the very essence of human progress and hope.

How Small Manufacturers are Building a Business Case for Robotics

Smaller manufacturers are the fastest-growing area of industrial robotics today, driven by the need for new collaborative robotics systems.

Reshoring with robots - UK manufacturers can use automation to bring production back home

The advantages of all-electric injection moulding machines demonstrate how automation and robots can help manufacturers bring their operations back home to the UK. Reshoring can be achieved with cost- and energy-efficiency as well as productivity benefits.

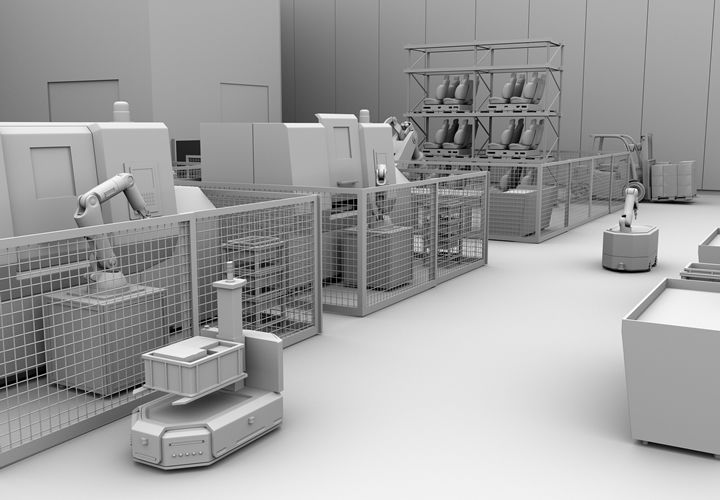

Factories of the future - What will manufacturing facilities look like in 2044

The landscape of manufacturing is set to evolve dramatically over the next two decades, as cutting-edge technologies redefine the way we produce goods. To envision what the future may look like, we do not need to rely solely on idle speculation.

Fiber Alignment and Photonic Chip Test & Assembly Just Got Easier

The new algorithm and technology have the potential to drastically reduce complex fiber alignment and photonics alignment procedure times by several orders of magnitude, surpassing any other existing technique used for automated fiber optic alignment in the market.

Five challenging applications automated with AI-powered robots

Robots equipped with AI vision systems, such as MIRAI, can perceive and adapt to their surroundings. This allows them to handle variance while performing complex tasks, making it possible to automate operations otherwise considered too complex to solve.

Optimizing Material Handling Processes for Increased Efficiency

Over the past few years, all aspects of the warehousing sector have been automated and this naturally includes the materials handling processes. This automation has increased efficiency across the board as well as improving employee safety and productivity.

When You Need a Clutch Performer, Rent a Robot

Like most businesses, yours likely goes through production bursts. Maybe these are predictable surges, like seasonal upticks in demand for your products.

Apptronik and Mercedes-Benz Enter Commercial Agreement That Will Pilot Apptronik's Apollo Humanoid Robot in Mercedes-Benz Manufacturing Facilities

The partnership represents Apptronik's first publicly announced commercial deployment of Apollo and the first application of humanoid robotics for Mercedes-Benz

Records 1 to 15 of 1088

Factory Automation - Featured Product

Revolutionize Your PCB Prototyping Assembled in the USA: Fast Turnaround, High Quality

At MacroFab, we understand the challenges engineers face when searching for the perfect partner to bring their visions to life. Traditional overseas prototype factories may offer low-cost solutions but often have hidden compromises. Say goodbye to subpar quality, communication barriers, and frustrating delays - choose MacroFab for a stress-free, reliable, and professional prototyping experience.

.jpg)