Auto Pan-Tilt Camera System For Tracking Fast Moving Objects

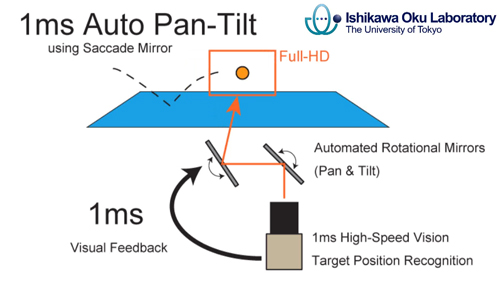

A team at the University of Japan have developed a camera system for tracking fast moving objects automatically and accurately without motion prediction. The example video shown on their website demonstrates the camera tracking a ping pong game. Even a high-speed object like a bouncing pingpong ball in play can be tracked at the center due to a high-speed optical gaze controller Saccade Mirror and a 1000-fps high-speed vision. The Saccade Mirror controls a camera's gazing direction not by moving the camera itself but by rotating two-axis small galvanometer mirrors. It takes no more than 3.5 ms even if it controls the gaze by 60 deg, the widest angle, for both pan and tilt. The newest prototype system accesses a Full HD image quality for an actual broadcasting service.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product