Parallella: $119 Parallel Computing Platform with 16-core Epiphany chip

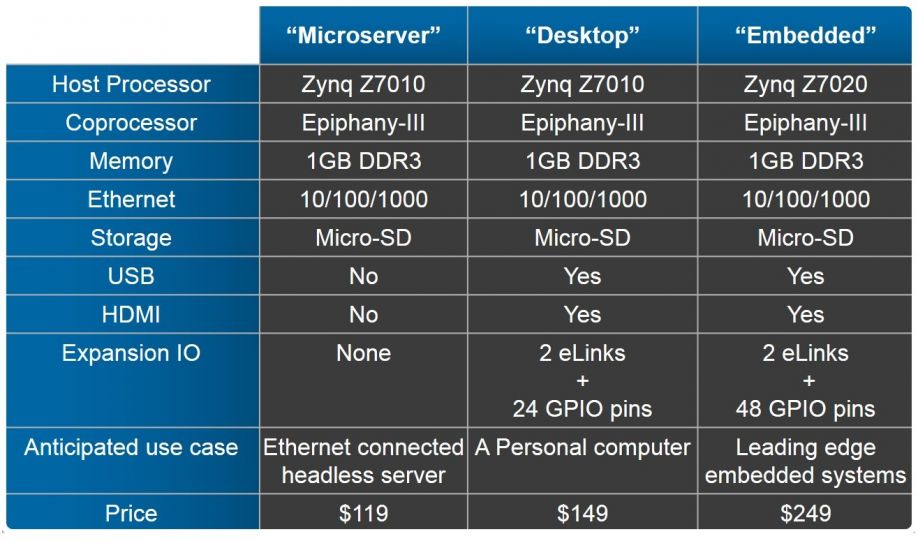

Parallella Computer Specifications:

The Parallella platform is an open source, energy efficient, high performance, credit-card sized computer based on the Epiphany multicore chips developed by Adapteva. This affordable platform is designed for developing and implementing high performance, parallel processing applications developed to take advantage of the on-board Epiphany chip. The Epiphany 16 or 64 core chips consists of a scalable array of simple RISC processors programmable in C/C++ connected together with a fast on chip network within a single shared memory architecture... (cont'd)

A realtime raytracing example running on the 16-core Epiphany chip:

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product