Routes to Professional Success in Automation

How to Optimize Your CV for a Robotics Engineer Career

FANUC America Launches New CRX Cobot E-Learning Website

How to Simplify the Integration of Robotic Automation

The Center for Robotics and Biosystems at Northwestern

RoboticsTomorrow - Special Tradeshow Coverage

PACK EXPO Las Vegas

iRobot Introduces the Root Coding Robot Through Acquisition of Root Robotics

Omron Helps University of Houston Engineering Students Gain Real-World Skills with New Design and Robotics Laboratory

maxon motor - Formulae Handbook for Design Engineers

Training at Applied Manufacturing Technologies Automation Academy

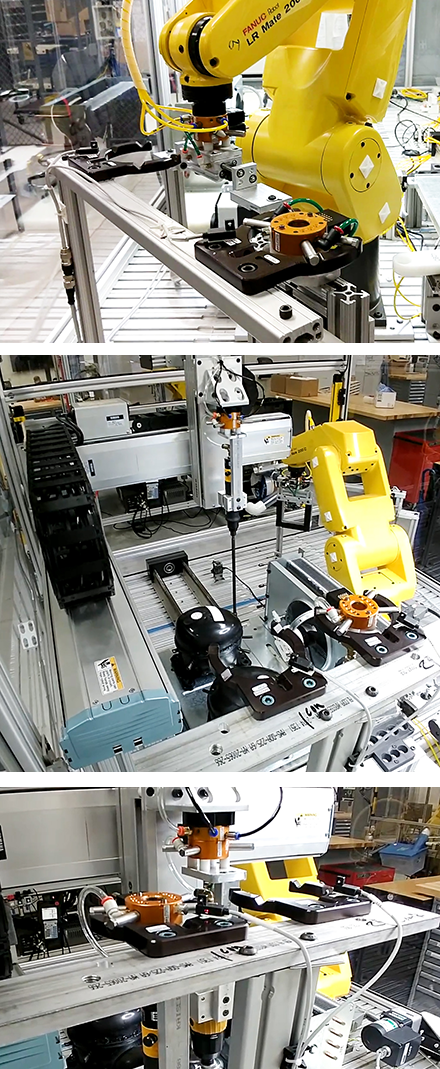

Madison College Takes ATI Tool Changers to School

Top Article for 2018 - How Artificial Intelligence and Robotics Can Create More Employment Opportunities

RoboticsTomorrow - Special Tradeshow Coverage

PACK EXPO International

More Than 69,000 Students Worldwide to Explore Teamwork and Advanced Technology with FIRST® Tech Challenge ROVER RUCKUS Presented by Qualcomm

What Are Robots Doing at Schools?

Records 16 to 30 of 92

First | Previous | Next | Last

Featured Product

.jpg)