Troubleshooting Robots - Enhancing Manufacturing Security Through Innovative Troubleshooting

Multi-couplings reduce down time and improve efficiency

Safeguarding Your PCBA Design From Electromagnetic Interference

Robots Can Support the Future of Bioplastics - Economical Manufacturing With Bioplastics Needs 6-axis Robots

Navigating the Shift: Industry 4.0 vs. Industry 5.0 - Welcoming the Next Wave of Innovation

Embracing a Purpose Built AIML System in Robotics

Advanced Ground Robotics Need Advanced Networking Solutions

Averting Factory Fires, Diminishing Downtime: How Thermal Imaging is Safeguarding International Production Lines

Top Viewed Articles of 2023

Trends in Industrial Robotics to Watch in 2024

Building Customers' Trust With Robots - Advanced 3D Vision Systems Improve Food Traceability

Unveiling the Unlikely: Surprising Sectors Transformed by Robotic Innovations

TinyML: What is It and Why Does It Matter

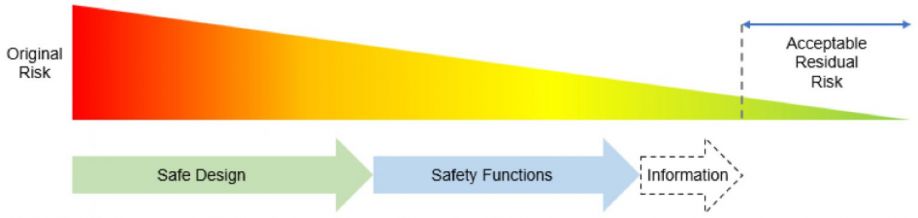

Machine Functional Safety - PL and SIL Ratings

What Are The Differences Between Safe LiDAR and LiDAR?

Records 16 to 30 of 725

First | Previous | Next | Last

Factory Automation - Featured Product