Chemical Manufacturing Leader Polysciences Partners With Formic to Introduce Automation To Their Production Process

Chinese cars in motion thanks to Stäubli connectors

ABB identifies new frontiers for robotics and AI in 2024

Nanopositioning and Motion Control Solutions for the Semiconductor Industry

Those who adapt the fastest win.

IMTS 2024 Offers Hidden Technology Gems, New Exhibitors

Troubleshooting Robots - Enhancing Manufacturing Security Through Innovative Troubleshooting

Anyware Robotics Emerges from Stealth Mode to Reveal Its Pixmo Robots for Container and Truck Unloading

Multi-couplings reduce down time and improve efficiency

Which Product Transfer is Best - Pros and Cons of 6 Transfer Methods

Safeguarding Your PCBA Design From Electromagnetic Interference

Why Multi-Camera Synchronization is a Key Feature in Cameras that Enable Autonomous Mobility

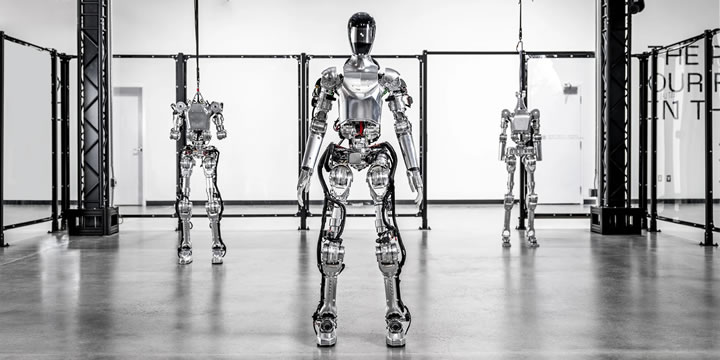

Figure announces commercial agreement with BMW Manufacturing to bring general purpose robots into automotive production

Robots Can Support the Future of Bioplastics - Economical Manufacturing With Bioplastics Needs 6-axis Robots

Navigating the Shift: Industry 4.0 vs. Industry 5.0 - Welcoming the Next Wave of Innovation

Records 16 to 30 of 1963

First | Previous | Next | Last

Industrial Robotics - Featured Product

.jpg)