DOOMSDAY CLOCK REMAINS AT 90 SECONDS TO MIDNIGHT

H2 Clipper Achieves Major Advanced "Swarm Robotics" Breakthrough For Large Scale Airship Manufacturing

Why Vision-Guided Systems Elevate Assembly Line Precision

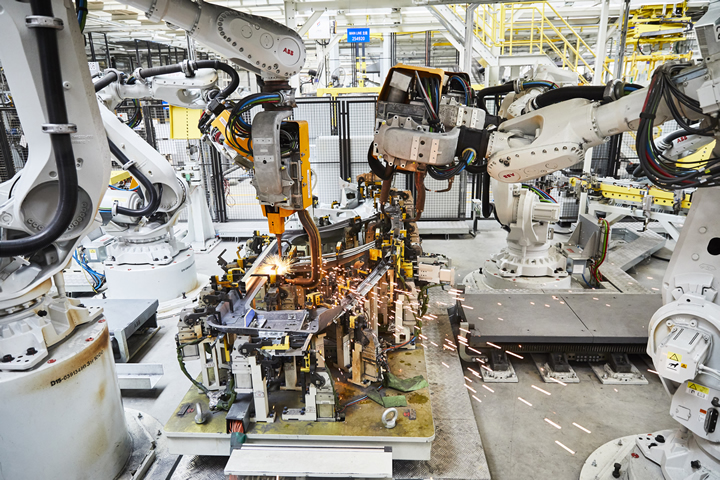

Smart robotic automation solutions from ABB to support sustainability targets for Volvo Cars

What's in store for 2024: Top 5 industry trends

This 3D printer can watch itself fabricate objects

Purdue Polytechnic to dedicate nation's largest smart manufacturing ecosystem for engineering technology

Introducing Titan, Amazon's new mobile robot that can lift up to 2,500 pounds

Delica Drives Efficiency with AGV Installation

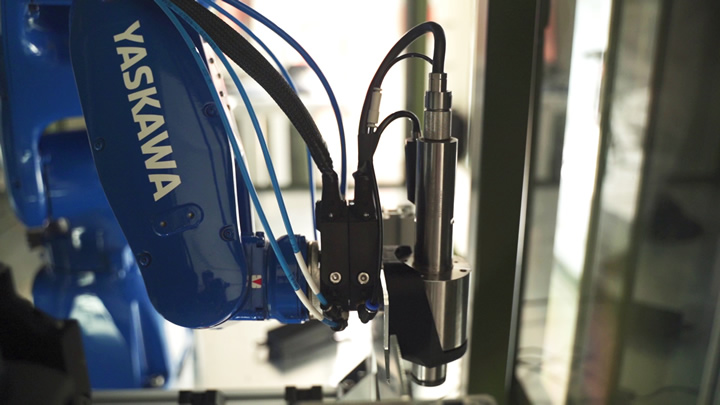

The World's First Dual-Arm Autonomous Robotic Sanding Cell

4 Ways Soft Gripper Robots Improve Food Processing

Running on fumes? AI isn't possible without proper data management

Warehouses may be the first industry to adopt humanoid robot workers

Omron Introduces the SWIR Camera Series Enabling Precision Inspection Across the Manufacturing Process Using Short Wave Infrared Technology

HARDWARE AS A SERVICE: A NEW PARADIGM FOR SERVICE CONTRACTS

Records 16 to 30 of 363

First | Previous | Next | Last

Factory Automation - Featured Product

.jpg)

.jpg)

.jpg)