The World's First Dual-Arm Autonomous Robotic Sanding Cell

4 Ways Soft Gripper Robots Improve Food Processing

ABB Robotics and Porsche Consulting collaborate to automate the construction industry

Running on fumes? AI isn't possible without proper data management

Warehouses may be the first industry to adopt humanoid robot workers

Omron Introduces the SWIR Camera Series Enabling Precision Inspection Across the Manufacturing Process Using Short Wave Infrared Technology

HARDWARE AS A SERVICE: A NEW PARADIGM FOR SERVICE CONTRACTS

ABB survey reveals unplanned downtime costs $103,000 per hour

Collaborating with AI and Robots - Busting Common Myths

ANSI/A3 R15.08-2 Safety Standard for Industrial Mobile Robot Systems and Applications Now Available

Spotlight on Fronius Welding Automation - Perfect Symbiosis of Welding Technology and Kinematics

EU Automation publishes new guide: How to Get Robotics Right - Avoiding the Common Costly Mistakes of Automation Adoption

Toyota Research Institute Unveils Breakthrough in Teaching Robots New Behaviors

ABB to invest $280 million in its European Robotics hub in Sweden

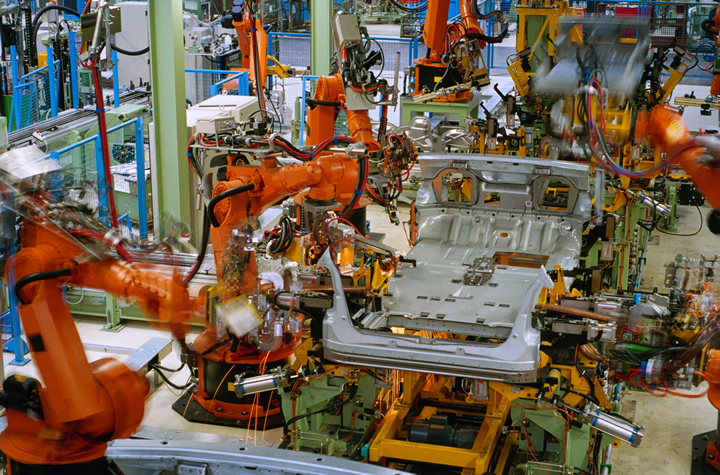

What role does automation play in the manufacturing supply chain?

Records 16 to 30 of 847

First | Previous | Next | Last

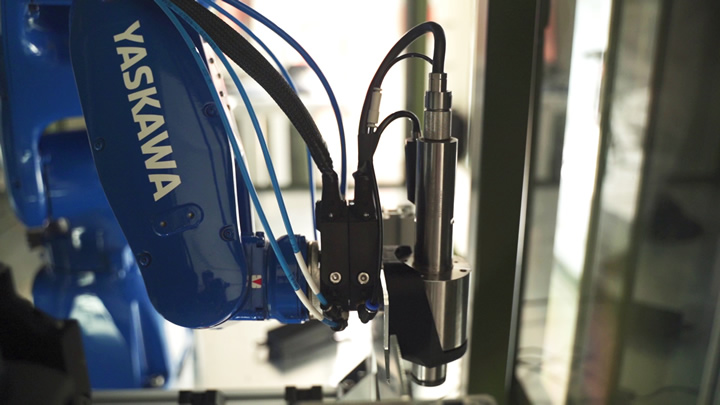

Industrial Robotics - Featured Product