What Are The Differences Between Safe LiDAR and LiDAR?

Why Industrial Robotics is Experiencing Steady Growth

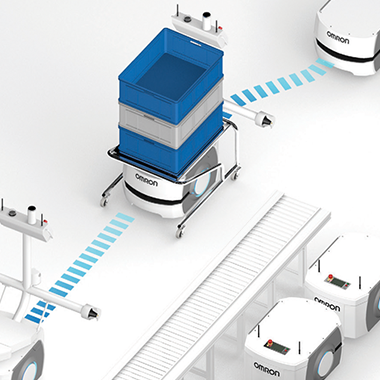

Synchronized Mobile Robot Fleets Bring New Versatility and Investment Protection to Assembly Operations

What's Holding Back Robot Adoption? - With the UK Lagging Behind Its Competitors, What Needs to Change?

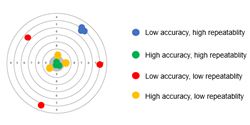

What are Resolution, Accuracy & Repeatability

Laser-Guided Vehicles: Supporting Sustainability in Manufacturing and Distribution

Implementing the Most Efficient Picking Paths to Meet Crucial KPIs

Automatic Loading and Unloading of Pressed Parts Through 3D Container Inspection

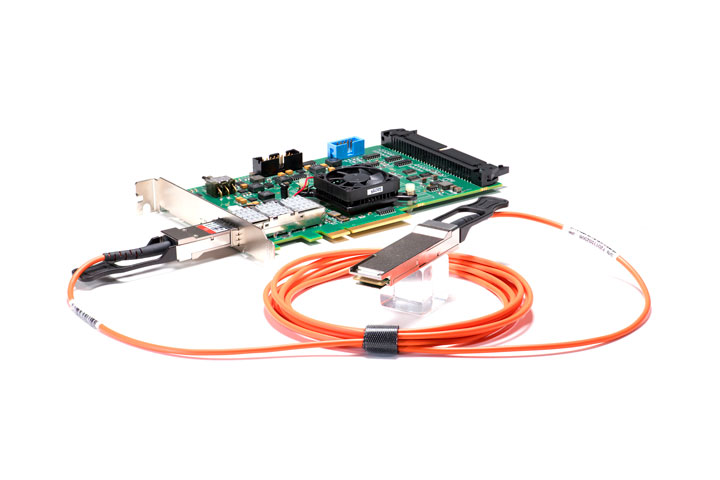

CoaXPress over Fiber

SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

Preparing Your Facility for Mobile Robots: Key Considerations for Seamless Integration

Important Trends Impacting the AMR Space

5 Advantages of Buying vs Making an Embedded Conveyor for OEM Applications

What Place Do Robots Have in the Future of eCommerce?

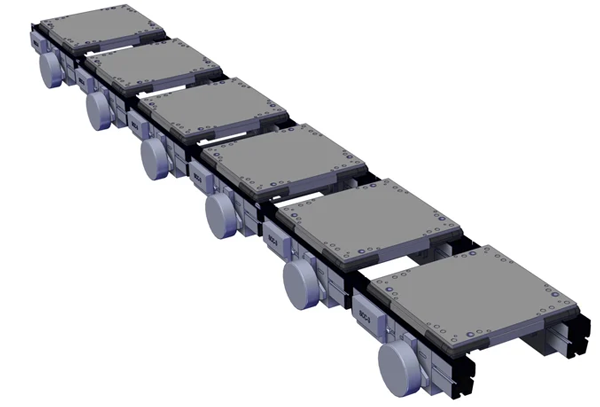

Case Study: Glide-Line's Zero Contact Zoned Conveyor For Integrator, Mid-South Industrial Automation

Records 31 to 45 of 726

First | Previous | Next | Last

Factory Automation - Featured Product