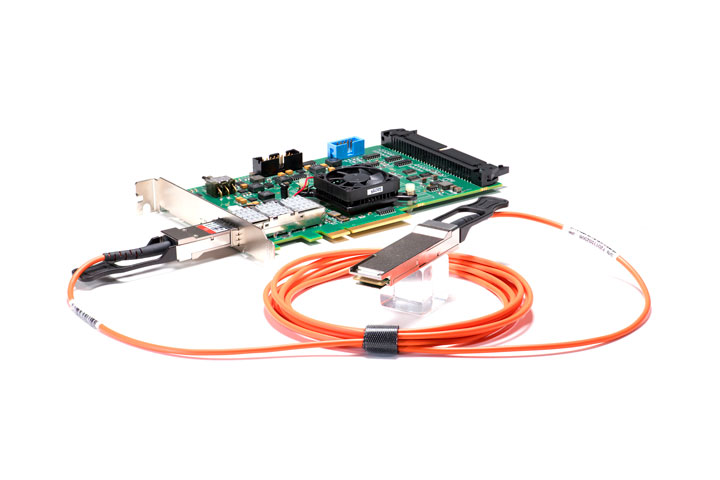

CoaXPress over Fiber

SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

5 Advantages of Buying vs Making an Embedded Conveyor for OEM Applications

How to Successfully Automate Packaging in Low-volume, High-mix Production

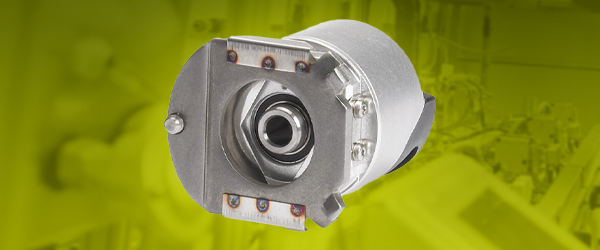

Why Rotary Encoders Might Be the Best Fit for Your Industrial Robotics Design

Case Study: Delta Line Motion System Solutions for Robotics

Bringing Robotics to Small Manufacturing

PACK EXPO 2023 Product Preview

Talking PACK Expo with Brenton Engineering

Why Letting the Machines Do the Tending Will Open the Door to the Next Industrial Revolution

Renaissance of Robotics: The Top 10 Marvels in the Post-COVID Age

The Rise of the Robots - So What?

Integrating Robotics and Autonomy into Industrial Environments

Have You Looked at Automating Fabrication Tasks in the Past? Why Didn't You?

Optimizing Servo System Performance: A Comprehensive Guide to Eliminating Electrical Noise and Enhancing Noise Immunity

Records 31 to 45 of 1113

First | Previous | Next | Last

Industrial Robotics - Featured Product