What role does automation play in the manufacturing supply chain?

The Future Of Industrial Automation - Trends And Technologies To Watch

How Remote Industrial Robotic Control Makes the Most of Automation

CMES Robotics Introduces Innovative Mixed Case Palletizing Solutions

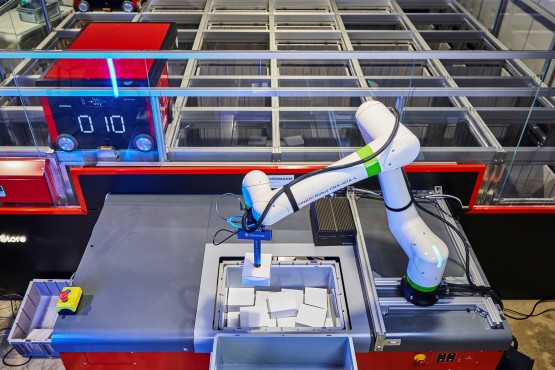

Tompkins Industries Reaches New Heights with its Vertical Lift Automation System

This 3D Printed Gripper Doesn't Need Electronics To Function

The Role of Robotics in Attracting Talent Back to the Warehouse

What is Digital Twin technology and why is it important for manufacturers?

Record Automate 2023 Event Leads to Annual Show

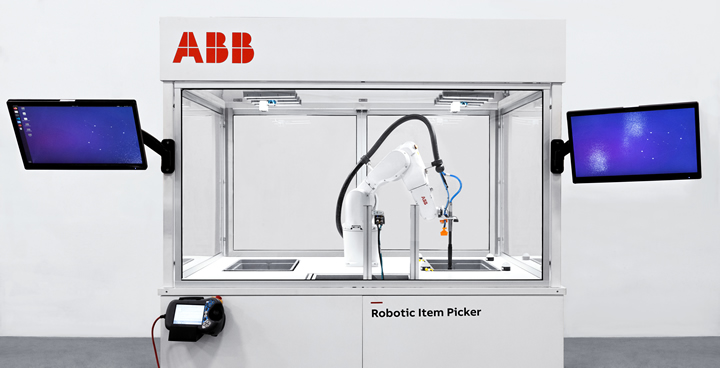

ABB predicts top US robotics trends

How the Talent Shortage Is Helping and Hindering the Field of Robotics

Climate-neutral, highly economical production through AI and digitization

Tackling the lack of specialists with innovative robotics solutions

The Top 5 Things Every Manufacturing CIO Should Know

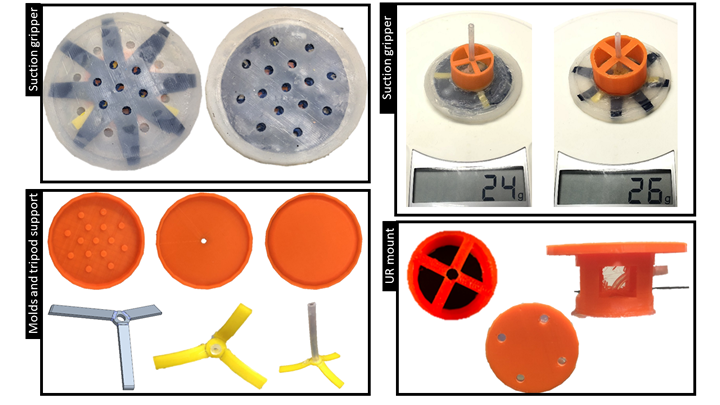

Sheet-Jamming Technology Revolutionizes Soft Robotics Grippers

Records 31 to 45 of 848

First | Previous | Next | Last

Industrial Robotics - Featured Product

.jpg)

.jpg)

.jpg)

.jpg)