Maximizing ROI for Mobile Robots: A Systems Strategy

Mobile robots are more than mere devices; they embody intelligence, communication capabilities, and mobility. The primary function is to transport goods, but it operates within the broader context of a business strategy.

Anyware Robotics Emerges from Stealth Mode to Reveal Its Pixmo Robots for Container and Truck Unloading

The Versatile Robots Unload Boxes More Safely, Cost-Effectively, Reliably, and Quickly than Manual Unloading Practices

How to Handle Post-Holiday Returns with Warehouse Automation

For retail warehouses, processing this flood of returns tests capacities and efficiency. But technologies like warehouse automation and robotics can transform returns management into a streamlined operation.

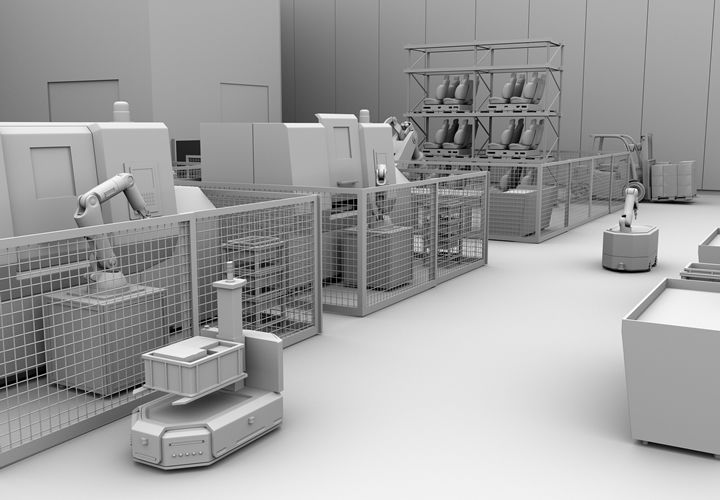

Synchronized Mobile Robot Fleets Bring New Versatility and Investment Protection to Assembly Operations

A trend toward replacing those fixed, conveyor-based assembly lines with fleets of mobile robots holds the promise of another step change in manufacturing efficiency and new adaptability to market volatility.

Laser-Guided Vehicles: Supporting Sustainability in Manufacturing and Distribution

Compared to conventional lift trucks, LGVs provide more consistent throughput of pallets between manufacturing and distribution functions, less damage to racking, raw materials and merchandise, reduced labor requirements, and lower cost of operation.

Warehouses may be the first industry to adopt humanoid robot workers

With the news that Amazon is testing a humanoid robot - Agility Robotics' Digit - in its warehouses, we explore what the future looks like for bipedal robots in logistics.

Dexterity AI and FedEx Unveil First-of-its-Kind Robotics Trailer Loading Technology

Dexterity AI focuses on the complexity of truck loading by giving mobile robots a suite of intelligence ranging from the ability to see, touch, think, and move quickly to pack trailers with stable, dense walls of randomized boxes.

Stack AV Launches Autonomous Trucking Business to Revolutionize the Transportation of Goods

Stack AV is developing AI-powered technology to maximize trucks' uptime, optimize existing infrastructure, improve roadway safety, and minimize emissions. Stack AV is backed by SoftBank Group Corp.

Clevon's T-Mobile Powered Autonomous Delivery Robot Fleet Zooms Into Smart City Peachtree Corners

The company's autonomous robot carriers (ARCs), powered by T-Mobile connectivity, are designed to collect orders at warehouses, retail stores, dark stores and micro fulfillment centers, and then deliver those goods to people and businesses around the city.

Forklift Safety: AGVs to the Rescue

As a relatively new addition to site operations, standards and data on AGV safety are still developing, but some AGV manufacturers are going above and beyond the minimum requirements to help ensure accident-free operations.

KPI INTEGRATED SOLUTIONS OPENS FIRST FULL-SCALE DEMONSTRATION SITE IN NORTH AMERICA FOR NEW GEEK+ FOUR-WAY SHUTTLE SOLUTION

As part of a KPI-designed operation that increases storage capacity, boosts throughput, and builds flexibility, the Geek+ Four-way Shuttle supports multiple picking and storage strategies for pallets, containers, and individual units.

Cincoze DI-1000 Drives AGVs in Factories and Warehouses

An enormous warehouse necessitates mapping of thousands of positions, and for the system to track order numbers and individual products on the pallets while transmitting information wirelessly back to the central control room for collection and monitoring.

Increase Manufacturing Efficiency with MiR Robots | AHS

As the labor pool continually changes and work environment standards become higher, it is becoming more difficult to attract and retain employees that are willing to perform repeatable, monotonous tasks.

Pallet Moving Robots Are Game Changers - And Easy to Implement Fast

Even if you don't have immediate plans to add robotic automation to your order picking process, you can still leverage the benefits with pallet moving robots. These robots improve the workflow at the transport dock - improving the speed to unload and load trucks.

Autonomous Navigation - With Millimeter Precision

In the age of the Internet of Things (IoT) and Industry 4.0, intralogistics plays an increasingly important role. The precise transport of goods and materials will become a key factor in efficient production.

Records 1 to 15 of 70

Featured Product

uEye XC AUTOMATICALLY PERFECT IMAGES

Combining the ease of use of a webcam with the performance and reliability of an industrial camera? The uEye XC autofocus camera from IDS Imaging Development Systems proves that this is possible. Its high-resolution imaging, simple setup and adaptability make it an invaluable tool for improving quality control and streamlining workflows in industrial settings - especially for cases where users would normally employ a webcam. The uEye XC autofocus camera features a 13 MP onsemi sensor and supports two different protocols: USB3 Vision, which enables programmability and customization, and UVC (USB Video Class). The UVC functionality enables a single cable connection for easy setup and commissioning, while delivering high-resolution images and video. This makes the uEye XC camera an ideal option for applications that require quick setup and need to manage variable object distances. Additional features such as digital zoom, automatic white balance and color correction ensure precise detail capture, which is essential for quality control.