Brushless Motors: What's the Big Difference?

The electronic switching of currents to the coils of the BLDC motor is more efficient than the mechanical switching of the DC motor.

Siemens' World-record Electric Aircraft Motor Punches Above Its Weight

From Gizmag: Researchers at Siemens have created a new prototype electric motor specifically designed for aircraft that weighs in at just 50 kg (110 lb) and is claimed to produce about 260 kW (348 hp) at just 2,500 RPM. With a quoted power five times greater than any comparable powerplant, the new motor promises enough grunt to get aircraft with take-off weights of up to 1,800 kg (2 ton) off the ground...

... As a result, the new aircraft electric drive system achieves a claimed weight-to-performance ratio of 5 kW per kilogram. This ratio is an exceptional figure – especially if compared to similarly powerful industrial electric motors used in heavy machinery that produce less than 1 kW per kilogram, or even to more efficient electric motors for vehicles that generate around 2 kW per kilogram... (full article)

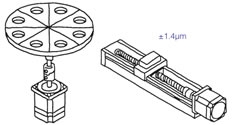

Everything You Need to Know About Stepper Motors

Recent servo motors are equipped with the encoder of 20 bits (1,048,576 steps) which has a very fine resolution. Because of this, errors due to the encoder installation accuracy have a huge effect on stopping accuracy.

Oriental Motor Introduces New KIIS Series Three-Phase Standard AC Motors in 200 W (1/4 HP) with Hypoid Gear

Our Most Compact, Highest Performing and Most Efficient Three-Phase AC Motor Just Received a Boost in Power and Performance

Spinning motors just got simpler with TI's latest stepper technologies

AutoTune™ technology dynamically tunes motors, and integrated current sensing saves 20 percent board space

Development of Battery-Free Multi-Rotation Absolute Encoder

In recent years, there have been many demands for equipment with high productivity to have a system that retains positioning information, even after the main power supply is turned off.

High Performance Drive in a Small Package

Maxon sets new standards in micro drives.

Service Robots Use Flat Motors

Service robots being designed for the disabled must be reliable, safe, and easy to use. Having the right motion system components is essential for these highly specific applications.

Records 1 to 8 of 8

Featured Product

REIKU's Cable Saver™ - The Most Versatile Modular Robotic Cable Management Solution

REIKU's Cable Saver™ Solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labor costs. It's available in three sizes 36, 52 and 70 mm.

All of the robots cables and hoses are protected when routed through the Cable Saver™ corrugated tubing.The Cable Saver™ uses a spring retraction system housed inside the Energy Tube™ to keep this service loop out of harms way in safe location at the rear of the Robot when not required. The Cable Saver™ is a COMPLETE solution for any make or model of robot. It installs quickly-on either side of the robot and has been tested to resist over 15 million repetitive cycles.

REIKU is committed to providing the most modular, effective options for ensuring your robotic components operate without downtime due to cable management.

www.CableSaver.com