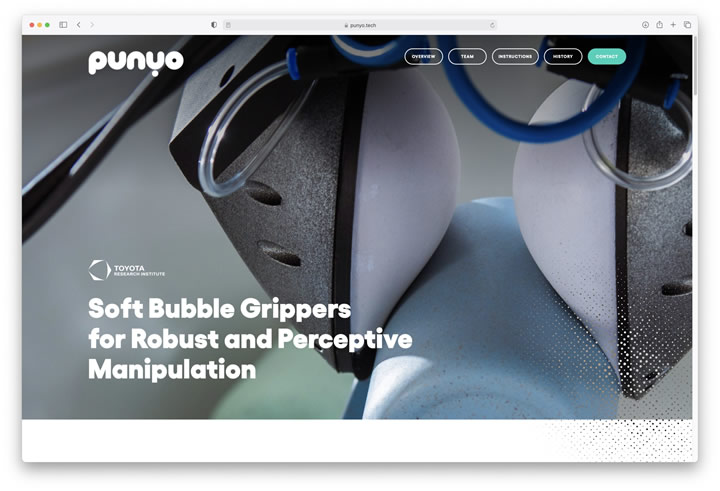

Toyota Research Institute Shares Design to Help Advance the Field of Soft Robotics

The Toyota Research Institute (TRI) is helping to accelerate the field of soft robotics by sharing the design source files and full build instruction for its innovative domestic robot hands.

How Open-Source Robotics Hardware Is Accelerating Research and Innovation

Erico Guizzo for IEEE Spectrum: Weve seen how, over the last several years, open source software-platforms like the Robot Operating System (ROS), Gazebo, and OpenCV, among others-has played a huge role in helping researchers and companies build robots better and faster. Can the same thing happen with robot hardware?

Rethink Robotics Leads in Research and Education with Open Source SDK

Introduces high performance Sawyer robot with software development kit

9 open source robotics projects

Jason Baker for OpenSource: Open source isn't just changing the way we interact with the world, it's changing the way the world interacts back with us. Case in point: open source robotics.

Robots are playing an increasing role in our world, and while we perhaps haven't reached the utopian future with robotic housekeepers imagined for us in the Jetsons, robotics are making advances in fields that fifty years ago would have been completely unimaginable.

While undoubtedly manufacturing has been one of the biggest beneficiaries of the robot renaissance, we are seeing robots enter the mainstream as well. Many of us have robots that clean our floors, clear our gutters, mow our grass, and more.

And now, with the advances of self driving cars, drones, and other transport technologies, the line between what is a robot and what is a vehicle is steadily blurring.

But let's be honest: a lot of us have an interest in robotics simply because it's fun! And the good news is you don't need to be an electrical engineer to enjoy robotics as a hobby. Fortunately, there are a number of open source projects out there that can help even the most novice beginner get started. Full Article:

Records 1 to 4 of 4

Featured Product

Harmonic Drive - Simplify with our New, Innovative Family of Compact Rotary Actuators with Integrated Servo Drive!

The SHA-IDT Series is a family of compact actuators that deliver high torque with exceptional accuracy and repeatability. These hollow shaft servo actuators feature Harmonic Drive® precision strain wave gears combined with a brushless servomotor, a brake, two magnetic absolute encoders and an integrated servo drive with CANopen® communication. This revolutionary product eliminates the need for an external drive and greatly simplifies wiring yet delivers high-positional accuracy and torsional stiffness in a compact housing.