Talking IMTS with Octopuz

OCTOPUZ will be exhibiting at IMTS 2018 located at booth #236036. At IMTS we will be showcasing the latest version of OCTOPUZ 2.0.3 released fall 2018.

Securing The Robots

There is no magic bullet for robot security. They are simply devices executing code, which are just as likely to be compromised as any other device in an organisation.

Talking AUTOMATE 2017 with Mobile Industrial Robots (MiR Robots)

We will be exhibiting our MiR100™ robot-a collaborative and safe, cost-effective autonomous mobile robot that quickly automates internal transportation and logistics.

Talking AUTOMATE 2017 with Eddie Stevenson, DENSO

DENSO will be leading an Expert Huddle this year at Automate. The discussion topic will be "How do you Determine the True Cost of Ownership for Robotics?"

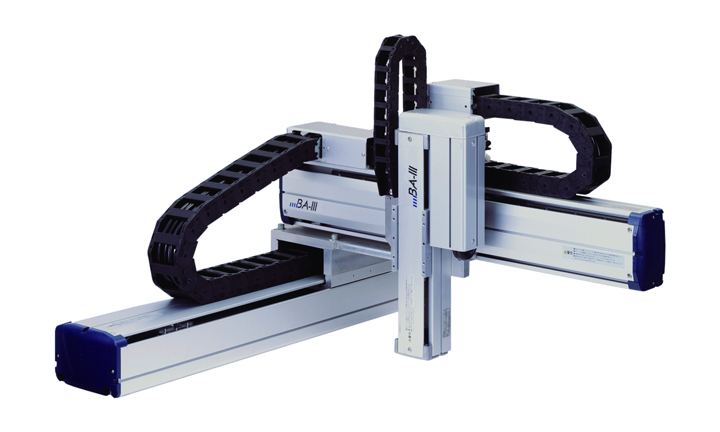

Talking AUTOMATE 2017 with TM Robotics

TM Robotics will be announcing the newest 6-axis robot from Toshiba Machine. Customers are looking for light to medium duty robots to perform tasks, without breaking the bank.

Talking AUTOMATE 2017 with ATI Industrial Automation

We will feature four live robotic demonstrations and a variety of products on display in our booth. Our knowledgeable account managers will be on site as well to help with your specific applications.

Talking AUTOMATE 2017 with Ken Wyman of Allied Motion

This is Allied Motions inaugural exhibition at Automate. So visitors will see, many for the first time, our capabilities and products for automation industry solutions.

InterDrone Las Vegas Welcomes Leading Venture Capitalists to Program. Accel Partners to Sponsor Start-Up Zone

Largest North American Drone Conference Creates Dynamic Environment Called The Hangar for Start-Ups to Connect With Leading Funding Companies; Adjoins Main Expo Hall, Includes Targeted Panel Sessions

Sciaky, Inc. to Highlight New Metal Additive Manufacturing Systems at RAPID 3D Printing Event in Long Beach, CA

The RAPID 3D Printing Event takes place May 19-21 at the Long Beach Convention Center in Long Beach, California.

SIMM, South China's largest machinery trade show, opens today

More than 1,100 international and local exhibitors to showcase intelligent manufacturing technologies that are set to transform the industry

Records 1 to 10 of 10

Featured Product

The maxon IDX Compact Drive with Integrated Positioning Controller

The compact brushless EC-i motor combined with an EPOS4 positioning controller delivers a highly dynamic, powerful drive package with field-oriented control (FOC), high efficiency, and maintenance-free components in a high-quality industrial housing. The maxon IDX drives are suitable for use across the entire speed range (from standstill to maximum speed) and have an extremely high overload capability. Together with a positioning controller, the integrated sensor (single turn) enables absolute positioning.