Implementing Advanced Vision Systems for Safer Robotics

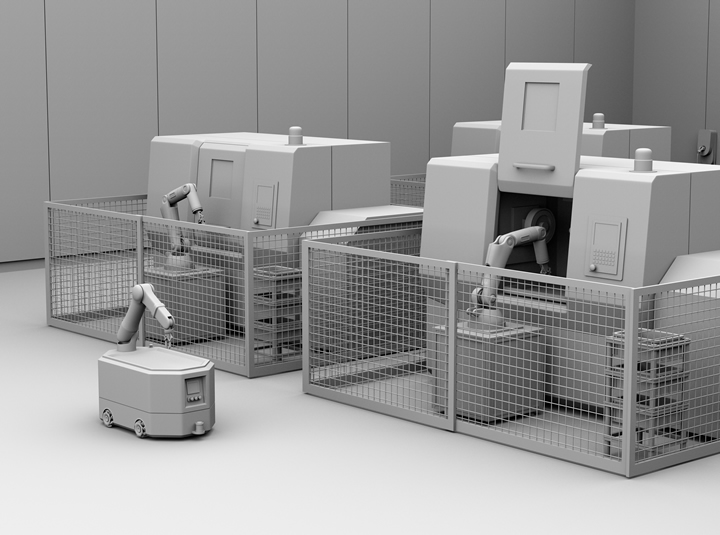

Robots could revolutionize workplace safety. For that to happen, though, the organizations employing this technology must equip it with tools to help it recognize and respond to hazards. That means capitalizing on machine vision.

Global cricket ball manufacturer uses automation with a vision system for efficiency and upskilling

The plan was to place the full trays of cricket ball covers into the dispenser, feeding trays automatically to the TVL700 robot to load and unload the trimming machine. This requires only one operator to load a set of trays every 20 to 25 minutes.

ABB Robotics launches global startup challenge to accelerate innovation in robotics and AI

Startups and scaleups to submit ideas in natural language programming, skill learning, and autonomous decision-making. Winners gain access to ABB's global network, cutting-edge technologies, and long-term partnership opportunities

Tips for choosing a 3D vision system - The future of vision systems in manufacturing

Advanced 3D vision systems are a stark contrast to the vision software of manufacturing's past. Many existing systems still require professional CAD programming to ensure the robot can recognise shapes.

The Interplay Between Robotics and Artificial Intelligence in Manufacturing

AI and robotics make the factories of the future smarter and more efficient. Manufacturers need to use these exponential technologies to gain a competitive advantage.

Special Agents: Chemical Weapons Disposal Done Right

The M55 rocket stockpile was successfully destroyed without any major incidents. With so many complex systems, processes, and disposal procedures, the Robosuits played a key role in ensuring that all of the careful planning and timing would not be disrupted.

The rise of modular robots and the importance of drive train design

As part of an in-house robot build, optimizing the drive train that powers and controls each joint is vital to the robot's performance. The most effective way of achieving this is by developing the drive train as a complete module.

NVIDIA and Alphabet's Intrinsic Put Next-Gen Robotics Within Grasp

Intrinsic, a software and AI robotics company at Alphabet, has integrated NVIDIA AI and Isaac platform technologies to advance the complex field of autonomous robotic manipulation.

Automate 2024 Product Preview

Automate 2024 takes place May 6th - 9th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

NREL Invites Robots To Help Make Wind Turbine Blades

Although robots have been used by the wind energy industry to paint and polish blades, automation has not been widely adopted. Research at the laboratory demonstrates the ability of a robot to trim, grind, and sand blades.

Kawasaki Robotics Shares First Look of New Collaborative Robots, Features New Partnerships and Applications for Industrial Robots at AUTOMATE 2024

At Automate Kawasaki Robotics introduces a line of intelligent cobots and showcases Ai-enabled R and BX Series robots for welding, multi-SKU palletizing and depalletizing as examples of limitless opportunities and human ingenuity

Edge Computing and AI in Manufacturing

With Tacton we wanted to give users the flexibility and configuration options they need to outfit their facility, while ensuring the system was reliable, secure, and easy to install.

Talking AUTOMATE 2024 with TM Robotics

Visitors will have the chance to see the entire THE robot range, including the THE400, THE600, THE800 and THE1000. The line-up includes robots of different sizes and strengths, providing visitors with an opportunity to find the perfect model for their application.

Talking AUTOMATE 2024 with TECH RIM Standards

TRS has been active with A3 for years, and as the Detroit show proved --- there are tremendous opportunities at Automate.

Talking AUTOMATE 2024 with DESTACO

Witness the power of precision movement, workholding, and indexing technology that will take your operations to new heights. Our booth is packed with ultra-precise end-of-arm tooling, state-of-the-art conveyors, and other top products from CAMCO, Ferguson and Robohand.

Records 1 to 15 of 1977

Industrial Robotics - Featured Product

TM Robotics - Shibaura Machine THE SCARA range

The THE range from Shibaura Machine is an extensive line up of SCARA robots. Available in four arm lengths THE400 (400mm), THE600 (600mm) and the most recent THE800 (800mm) and THE1000 (1000mm), this range is suitable for assembly, handling, inspection and pick and place processes in varied industrial applications. The THE1000 boasts a 20kg payload capacity and an impressive 0.44 second cycle time, providing high speeds for processes with large components. In fact, the range has been recognised for as the price-to-performance leader compared to other SCARA models in its price range due to its impressive speed versus payload capacity.

.png)

.jpg)