A warehouse is the place, building or industrial plant where goods are manufactured, handled and/or stored before distribution, use or subsequent sale. Each warehouse is different in terms of its structure, capacity or space, just as the activities that take place in it. Robotnik explores the benefits of using robots for warehouse management solutions and automating processes.

Whatever its characteristics, the fact is that the warehouse innovation ensures greater efficiency in production and, therefore, improves profitability.

Moreover, the concepts ‘warehouse innovation’ and ‘warehouse automation’ have a direct relationship with mobile robotics since, from the beginning, the development of this technology has been linked to the improvement of logistics processes in warehouses and factories.

This article provides answers to the 3 most frequently asked questions by end users regarding warehouse automation.

WHAT ARE THE BENEFITS OF USING MOBILE ROBOTS IN WAREHOUSE LOGISTICS?

Although their use is widespread, there are still users who wonder about the real benefits of mobile robots warehouse optimization. Here are 15 benefits of mobile robotics that improve the warehouse efficiency:

- Increased efficiency: mobile robots can autonomously transport and manipulate materials, which can significantly improve efficiency in warehouses and distribution centers.

- Reduced labor costs: logistics automation can increase profitability by reducing the need for labor and thus labor costs.

- Increased accuracy: mobile robots can perform tasks accurately and repetitively, reducing the possibility of errors and improving service quality.

- Increased safety: AMRs can work in hazardous or challenging environments without compromising worker safety.

- Reduced wear and tear on materials: mobile robots can handle materials with care and precision, reducing the risk of damaging them.

- Space optimization: mobile robots can move autonomously and use space more efficiently, increasing warehouse optimization.

- Increased flexibility: one of the advantages of AMRs is that they can easily adapt to different tasks and storage requirements, which improves the flexibility of the operation.

- Reduced downtime: mobile robots can work non-stop, reducing inactivity time.

- Improved service quality: mobile robots can improve service quality by speeding up processes and reducing errors.

- Increased speed: mobile robots can move quickly through the warehouse and reduce delivery times.

- Increased load capacity: Mobile robots can transport heavy and bulky loads without the risk of injury.

- Improved tracking and control: mobile robots can be equipped with sensors and tracking and control technology to provide real-time, up-to-date data.

- Reduced emissions: Mobile robots are a cleaner, greener alternative to fossil-fueled transport and material handling vehicles.

- Increased productivity: Logistics automation with mobile robots can improve overall warehouse productivity by reducing downtime and optimizing resources.

- Increased customer satisfaction: Logistics automation with mobile robots impacts customer satisfaction by speeding up delivery times, increasing production capacity, reducing errors and improving service quality.

HOW DO MOBILE ROBOTS IMPROVE WAREHOUSE EFFICIENCY?

There are different automated warehouse management solutions available (sorting systems, packaging systems, storage systems, etc.), but when it comes to material handling automation, the most efficient solution is autonomous mobile manipulation, as shown in these use cases.

Warehouse material handling automation is one of the most common and effective strategic operations in logistics environments. RB-KAIROS+ has been developed to automate this type of material handling processes, especially those that need to be carried out at different points within the same warehouse.

Despite popular perception, the incorporation of robotics or autonomous mobile handling in warehouses does not mean that the human team is no longer needed. Workers are still key in a warehouse, factory or logistics plant because of their creative and strategic capacity, which is far superior to that of mobile robots.

On the other hand, repetitive, heavy or dangerous material handling tasks can be delegated to an RB-KAIROS+ that will perform them without risk, injury or fatigue, thus allowing people to devote their efforts to more valuable tasks. The coexistence of humans and robots is already the current reality in Industry 4.0 since, an operator, after a short initial training, will be able to control and manage a mobile robot through Robotnik’s Advanced User Interface.

HOW DOES MOBILE ROBOT TECHNOLOGY INCREASE PRODUCTIVITY IN WAREHOUSES?

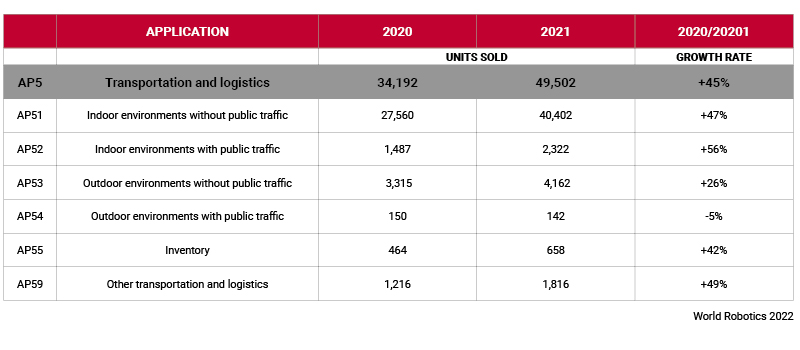

The data support the contribution of mobile robotics to the industrial environment. Specifically, the International Federation of Robotics throws out some revealing figures on logistics automation in warehouses:

- More than 49,500 robots were sold in 2021 for logistics or transport tasks in logistics environments (examples transport use cases).

- In 2021, up to 26% growth was experienced in robots such as the RB-VOGUI, trained for transport and logistics in outdoor environments.

- Transportation and logistics will also remain a group of applications with strong double-digit growth rates of 40% on average each year between 2022 and 2025.

To conclude this article by asking the question “How does mobile robot technology increase warehouse productivity?”, it can be stated that mobile robotics is revolutionizing logistics automation and exponentially increasing warehouse productivity. Mobile robots can perform repetitive tasks, move products at high speed and accuracy, and work without errors, significantly improving both warehouse operations and optimizing product distribution and reducing errors in the supply chain.