In the car manufacturing industry, having top-quality automotive seats is really important. But defects detection in the seats can be a challenge.

That’s where EasyODM comes in. It’s a special software that uses machine learning to spot defects quickly and accurately.

This case study showcases how EasyODM helped a one of the largest automotive seats producers worldwide to improve their quality control.

Challenges Faced

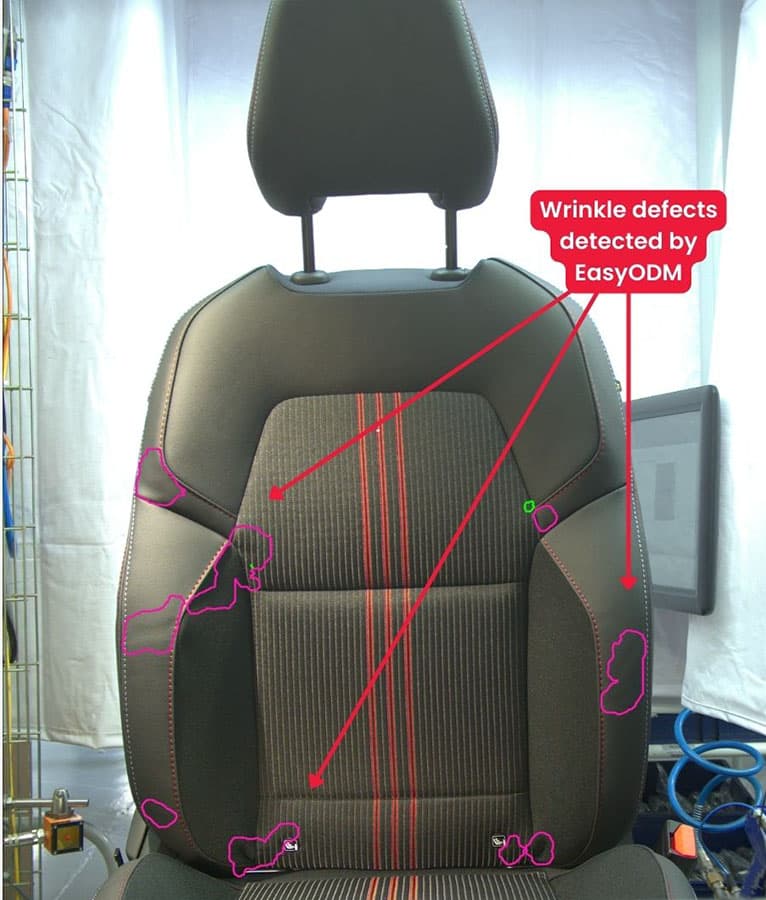

Our client, a leading automotive seats producer, faced a major obstacle in identifying and resolving wrinkles in car seat materials during production.

The traditional manual inspection was slow, laborious, and prone to mistakes. This not only resulted in more defects but also hindered overall efficiency and profitability.

The Solution

EasyODM, our advanced AI-powered quality inspection software, provided the ideal solution our client needed.

Through cutting-edge deep learning algorithms, EasyODM achieved exceptional precision and speed in identifying wrinkles across diverse seat materials.

This self-learning system seamlessly adapted to different surface types, empowering our client to produce more than 40 seat models for top car brands while maintaining uncompromising quality standards.

Once EasyODM’s machine vision inspection detects wrinkles, the seats are seamlessly transitioned to industrial robot ironer, which utilizes hot steam on the production line to smooth out the wrinkles in the car seats.

The Results

The implementation of EasyODM yielded impressive results for our client:

Customer Support and Training

At EasyODM, we prioritize providing exceptional customer support and comprehensive training to ensure a seamless experience for our clients.

Our dedicated support team is available to assist you throughout the onboarding process and beyond. We offer comprehensive training programs tailored to your organization’s needs, equipping your employees with the necessary skills to effectively utilize EasyODM.

Additionally, we provide ongoing technical support to address any questions or issues that may arise, ensuring continuous smooth operations.

With EasyODM, you can trust in our commitment to your success and our dedication to delivering top-notch customer support and training.

Frequently Asked Questions

-

How does EasyODM detect wrinkle defects in automotive seats?

EasyODM utilizes advanced machine vision technology and AI algorithms to analyze seat materials and identify wrinkle defects with high precision. Your team of manufacturing experts, in collaboration with EasyODM, leverages their industry knowledge to guarantee flawless processes.

-

Can EasyODM handle different seat models from various car brands?

Yes, EasyODM is designed to work with a wide range of seat models. Our client, the second-largest automotive seats producer, produces over 40 different seat models for leading car brands, and EasyODM successfully detects defects across all of them.

-

What are the benefits of using EasyODM for automotive seat quality inspection?

By employing EasyODM, our client significantly reduces inspection time from approximately 1 minute per part to just 2.2 seconds. This leads to improved efficiency and eliminates repetitive and tedious work for employees.

-

How accurate is the EasyODM system in detecting seat defects?

EasyODM boasts an impressive accuracy rate of 99%, thanks to its self-learning AI-based algorithms. This ensures reliable and precise detection of wrinkle defects, meeting the stringent quality standards of the automotive industry.

-

What is the return on investment (ROI) for implementing EasyODM?

The ROI for our client, the second-largest automotive seats producer, is projected to be less than 2 years. By automating the quality inspection process with EasyODM, they achieve significant cost savings, improved operational efficiency, and reduced tact time.

-

Can EasyODM be customized for detecting other types of defects in automotive seats?

Absolutely. EasyODM is a flexible software solution that can be trained to detect various types of defects beyond wrinkles, such as tears, stains, misprints, and more. It offers versatility to adapt to the specific quality control needs of automotive seat manufacturing.

-

Can EasyODM detect defects on different types of materials and surfaces?

EasyODM offers extensive customization capabilities, allowing the software to detect defects on a wide range of materials and surfaces. Whether it’s leather, cotton, synthetic fabric, wood, concrete, glass, metal, plastic, or other materials, EasyODM can be trained to inspect and identify defects accurately.

-

What about the technical aspects of EasyODM?

EasyODM is developed using a combination of C++, Python, and C# programming languages. To achieve superior output, we utilize cutting-edge global shutter cameras, high-quality lenses, and advanced LED lighting systems, along with computer hardware. These technical components work in perfect harmony to ensure precise and reliable detection of automotive seat defects.

-

What hardware cameras do you use?

We use premium industrial cameras with f=12mm lenses.

Conclusion

The case study of EasyODM’s collaboration with one of the largest automotive seats producers highlights the transformative power of our software in detecting and addressing defects.

The significant time reduction, enhanced accuracy, and substantial cost savings demonstrate the immense value EasyODM brings to the automotive manufacturing industry.

By automating quality inspection and empowering employees with advanced AI technology, EasyODM propels its clients towards operational excellence and improved profitability.

To learn more about the remarkable results achieved through EasyODM and experience its capabilities firsthand, request a live demo today.

Witness how EasyODM can revolutionize your automotive seats defects detection process and drive your business towards success.

Curious About The Above Solution?

Chat with Gediminas and explore your possibilities without any commitment.

Gediminas Mickus

Business Development Manager

Book a no-obligation free consultation with our expert.