Cobots are the future at Danish Alusteel where the large industrial welding robot is well on its way to being shut down. Skilled welders are in short supply so why not let them use their knowledge to instruct the robots?

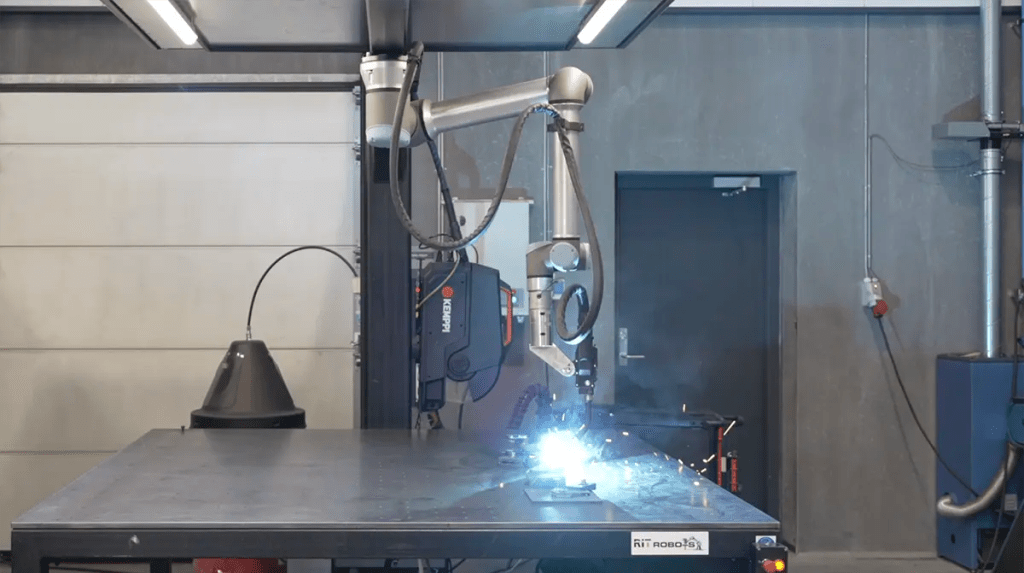

The welding arc precisely hits every single time. Fast, controlled movements and a completely consistent result every single time. A result of years of experience and professional expertise of a skilled craftsman – but performed by a robot doing exactly what it has been programmed to do.

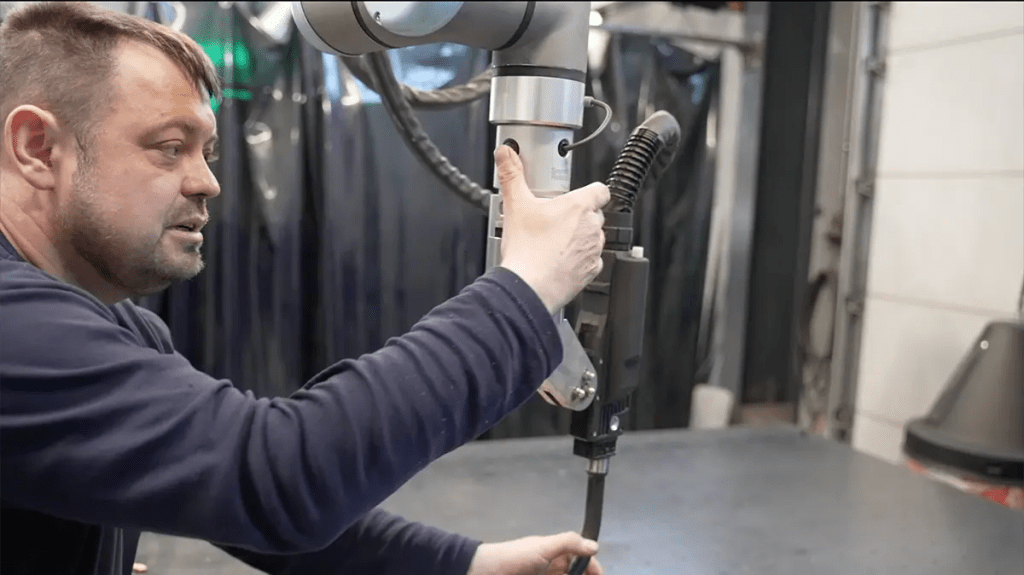

In the large production hall at Danish company Alusteel, Boguslaw Hara hands over welding to the robot arm from Universal Robots. He has been employed for eight years as a blacksmith at Alusteel and through 15 years as a welder in first his native Poland and now Denmark he is a highly skilled craftsman. He knows how to lay the perfect weld, making it durable, uniform, and aesthetic.

Boguslaw Hara made the first weld himself and with just a few presses of the welding arm’s two buttons, he programmed a revolutionary software that controls the robot arm so that it mimics the welding only a blacksmith with vast experience can produce.

And flawless welds are imperative for the family-owned company, which specializes in making components for industry – including for some of the largest Danish robot companies. Few copies of each part, but all executed with accuracy and precision. This requires expertise, but the global shortage of welders can also be felt in the small station town of Kværndrup, just south of world-renowned robot-hub Odense, where Alusteel is based. So, founder Mads Milling had to innovate in order to meet customer demand.

“There are very few skilled welders out there. That’s why the smaller robots are interesting – because they can help the welders. We already have a large industrial welding robot, but because we have a very differentiated customer base, each of whom ordering a small number of components, it made sense for us to find a solution where it is easy to program and where the result is impeccable,” says Mads Milling, who today heads a company, which has more than 50 employees.

Teaching the robot how to weld

Although the robots can handle some of the tasks, this in no way means that the human welder is superfluous. Rather, this means that the working day today is different, because now one of the most important tasks is to show your welding skills to the robot, which can then repeat endlessly – without getting tired. And in the meantime, the welder can then concentrate on those welds that require special skills. The grueling tasks are handled by the robot colleague, so the welder avoids stressful postures and toxic welding fumes.

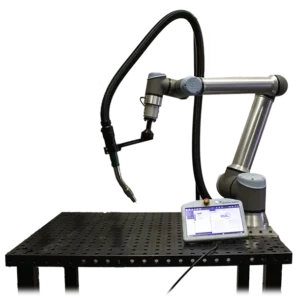

The interaction between the welder and the robot – or rather: the cobot, the collaborative robot – is the whole basic idea behind SmoothTool, the revolutionary solution from Smooth Robotics. A software that lets the skilled welder use all his skills, regardless of the type of power source he uses, and at the same time put a robot to work for him – without knowing anything about robots.

“We remove the complexity of a robot and let the welder program the robot with his actions. In this way, the welding is perfect – even when it is in progress for the hundredth time,” says Ahmad Gheit, lead software developer at Smooth Robotics.

For Mads Milling, this means that the welder and a cobot together increase productivity significantly and that the great flexibility in programming new welding jobs for the cobot means that it is quite a short-term task to set the cobot up for the next project.

The great advantage of the solution is that the welder can use exactly the power source he normally uses and connect it to the cobot, because the SmoothTool software is compatible with virtually all power sources. In this way, all the skilled welders can use their preferred welding solution, providing even greater incentive to use the cobot.

“For us, this means that a welder and a cobot are really like having three men at work. It’s really effective,” he says.

Production time has been reduced by 47%.

In a recent case the company had to make 30 pieces that required extensive welding. The manual version took 43 minutes to complete, but when partnering up with the cobot the welding time went down 47 %, to 23 minutes. In total the order was done in a little over 11 hours instead of the 21 hours, a manual welding process would have required – freeing the welder to do other tasks for more than a full workday.

Therefore, he is now considering investing in even more cobots that can be equipped with the software from Smooth Robotics. Because it makes far more sense than the large industrial robot, which requires far more attention.

“Based on our needs and the purely financial, it makes much more sense to us. We ensure uniform products, and our welders avoid the tedious and repetitive work. They are happy with their new colleague,” says Mads Milling.

About Alusteel

Production company focused on delivering high quality solutions to companies in automation, windmills and offshore, construction, automotive and industry.

- Founded in 2001 by Mads Milling

- 53 employees

- Based in Kværndrup, Denmark