Maximizing ROI for Mobile Robots: A Systems Strategy

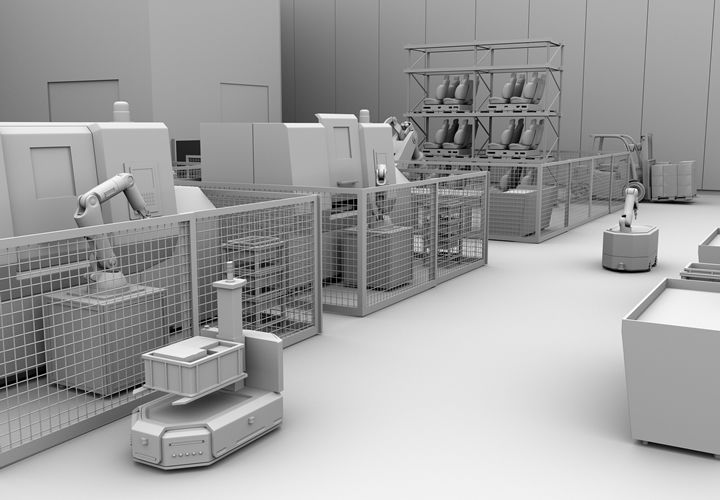

Mobile robots are more than mere devices; they embody intelligence, communication capabilities, and mobility. The primary function is to transport goods, but it operates within the broader context of a business strategy.

A Cut Above: Adding Next-level Protection for Next-generation Welding

By partnering with Roboworld since their first Cobot rolled off the line on Day 1, all of Vectis' robotic welding systems and teach pendants have included Robosuits® and Pendant Armor®.

Productivity Inc. Wants Your Robot to Do More

Using ATI's QC-11 Tool Changer and RCT-151 Radially-Compliant Deburring Tool along with a Renishaw probe, they produced a demonstration highlighting their expertise in aiding potential customers to maximize productivity of the robots already installed in their facilities

Fostering Innovation: The Keys to Success

In a world that's always evolving, innovation is how we keep up, grow, and thrive. So, when we talk about nurturing innovation, we're really talking about fuelling the very essence of human progress and hope.

Reshoring with robots - UK manufacturers can use automation to bring production back home

The advantages of all-electric injection moulding machines demonstrate how automation and robots can help manufacturers bring their operations back home to the UK. Reshoring can be achieved with cost- and energy-efficiency as well as productivity benefits.

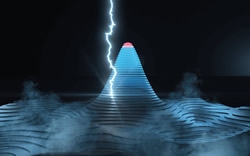

Fiber Alignment and Photonic Chip Test & Assembly Just Got Easier

The new algorithm and technology have the potential to drastically reduce complex fiber alignment and photonics alignment procedure times by several orders of magnitude, surpassing any other existing technique used for automated fiber optic alignment in the market.

Five challenging applications automated with AI-powered robots

Robots equipped with AI vision systems, such as MIRAI, can perceive and adapt to their surroundings. This allows them to handle variance while performing complex tasks, making it possible to automate operations otherwise considered too complex to solve.

Optimizing Material Handling Processes for Increased Efficiency

Over the past few years, all aspects of the warehousing sector have been automated and this naturally includes the materials handling processes. This automation has increased efficiency across the board as well as improving employee safety and productivity.

When You Need a Clutch Performer, Rent a Robot

Like most businesses, yours likely goes through production bursts. Maybe these are predictable surges, like seasonal upticks in demand for your products.

DC microdrives bring dynamics into handling

Miniature drives and microdrives can be found in virtually all areas of automation technology and have a correspondingly wide variety of applications. These range from medical technology and laboratory automation.

Chemical Manufacturing Leader Polysciences Partners With Formic to Introduce Automation To Their Production Process

With a unique capability of offering concept-to-commercialization services to their clients, making continuous production improvements for commercialization is a key focus.

Chinese cars in motion thanks to Stäubli connectors

Stäubli's MPS tool changer provides JAC with flexibility and minimal technician intervention during the manufacturing process, particularly during the handling and welding processes. Water, air and electrical circuits can be connected and disconnected simultaneously.

Nanopositioning and Motion Control Solutions for the Semiconductor Industry

Recently, the convergence of photonics and electronics, known as Silicon Photonics, has marked a significant advancement in both performance and the reduction of power consumption.

Why Do Hardware Startups Fail?

Hardware businesses are notoriously challenging in the vast, dynamic world of startups. There are over 72,500 startups in the U.S. alone, yet only half have a survival rate beyond five years. In hardware startups, the stats are even worse.

Those who adapt the fastest win.

A new type of tool changer now turns the specialist for large series into a flexible all-rounder, with which even small series and individual pieces can be produced economically.

Records 1 to 15 of 725

Factory Automation - Featured Product

Stäubli robotic tool changer solutions

Stäubli is a pioneer in the construction and development of robotic tool changing systems. Our customers benefit from our many years of expertise in all industry sectors, as well as our modular product concept, which offers three efficient solution paths: MPS COMPLETE offers preconfigured robotic tool changers for immediate use. MPS MODULAR allows the user to determine the configuration, while MPS CUSTOMIZED allows the construction of special, application-specific systems.