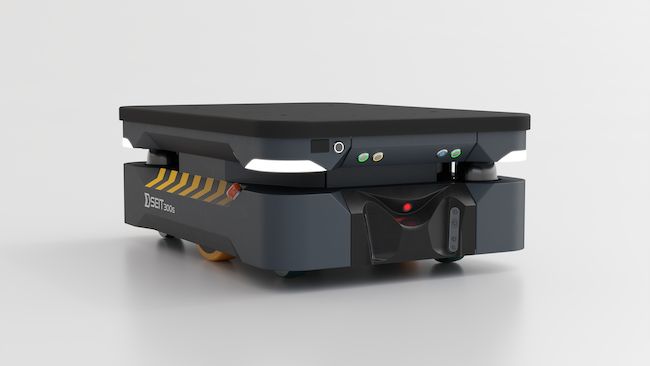

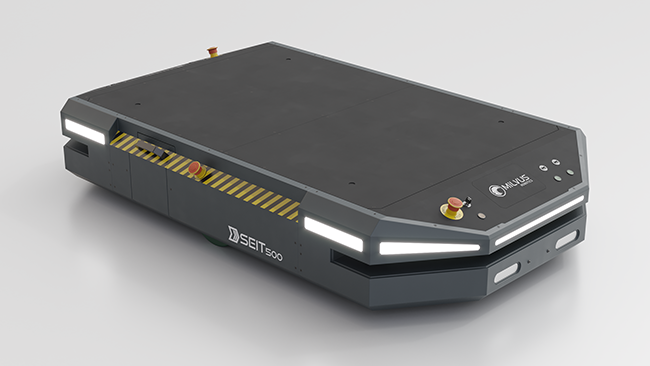

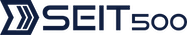

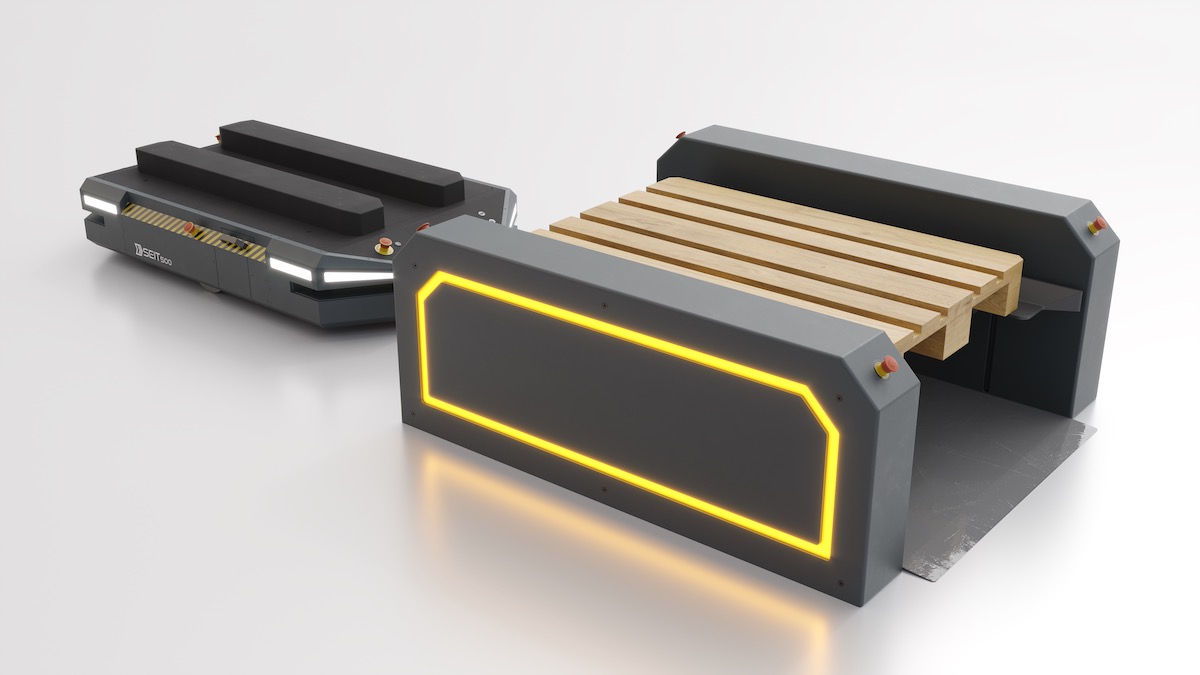

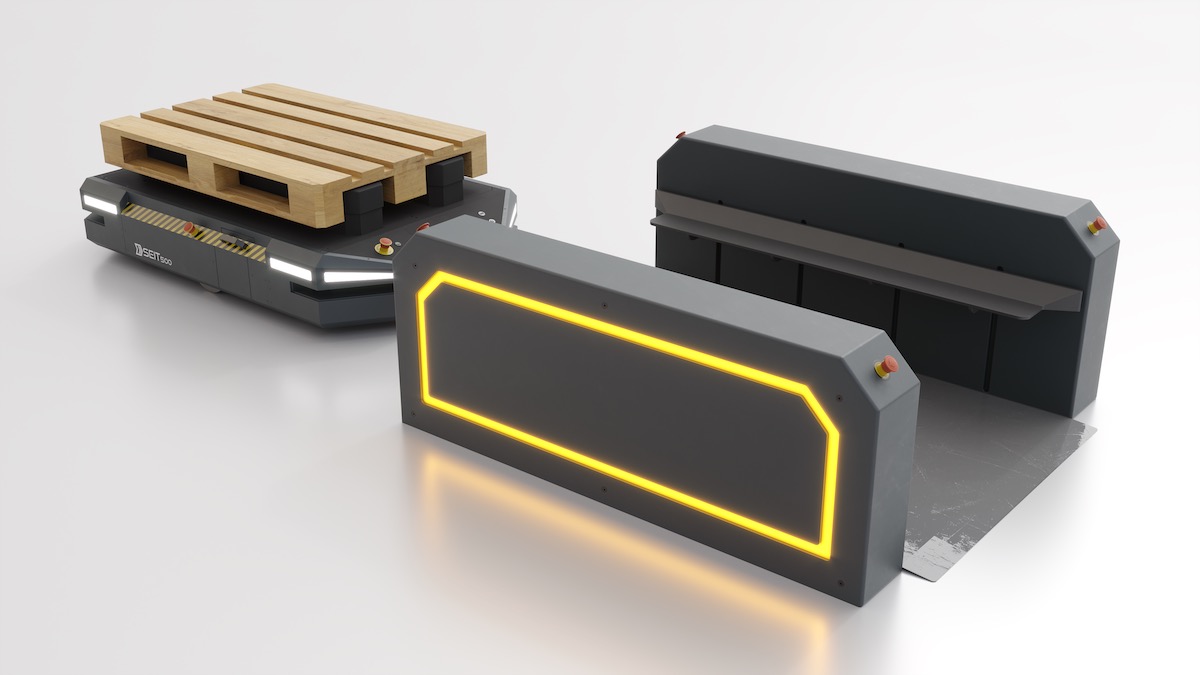

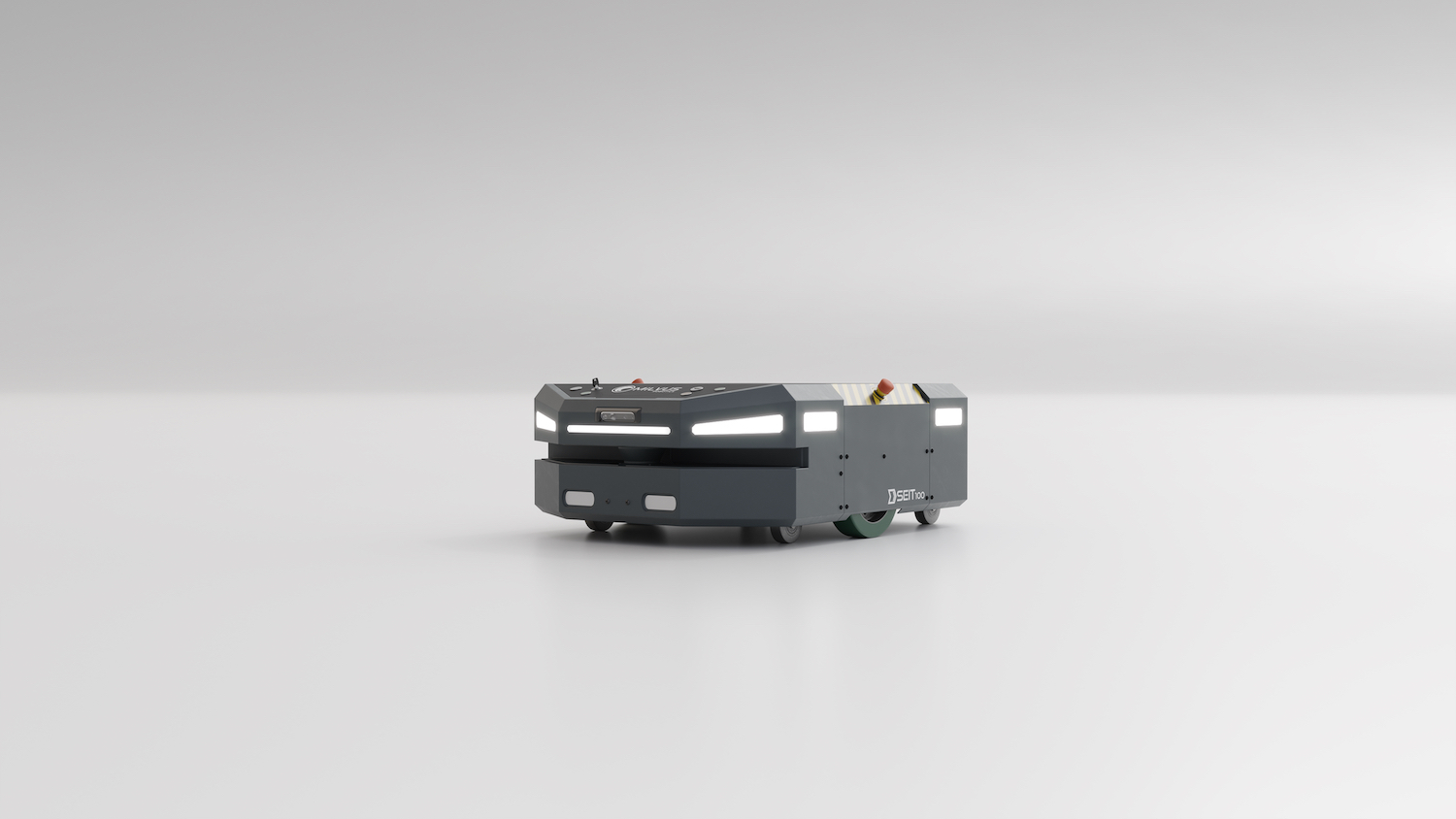

Infrastructure Free

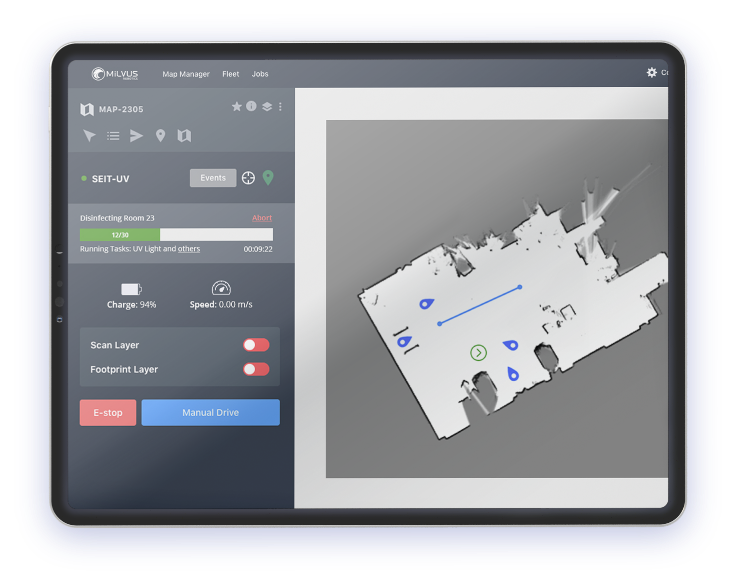

SEIT allows you to navigate throughout the facility or your warehouse, without having to commit any of your resources on infrastructure. SEIT’s navigation requires no physical markers, such as, magnets, beacons, wires or tapes. This means, there will

be no interruption to your operation and no physical changes to your facility. Furthermore, the lack of fixed infrastructure not only provides an initial savings, but also signifies a reduction in future infrastructure costs as these tooling and

equipment undergo wear and tear, or might be replaced all together if the production lines change.

Precise

Precise, is one of the many words that we can use to describe SEIT. But perhaps, it is one of the most crucial ones since manufacturing requires exact precision. SEIT can provide this level of precision, following your commands and execute them on

time, repeatedly and consistently, saving you to worry from possible downtime and the costs come with it.

Safe

SEIT is compatible with recent international safety standards. Furthermore, SEIT’s proactive sensing capabilities not only prevents accidents, but they also benefit the users in terms of reduced accidents and injuries as well as less compensation in

these regards.

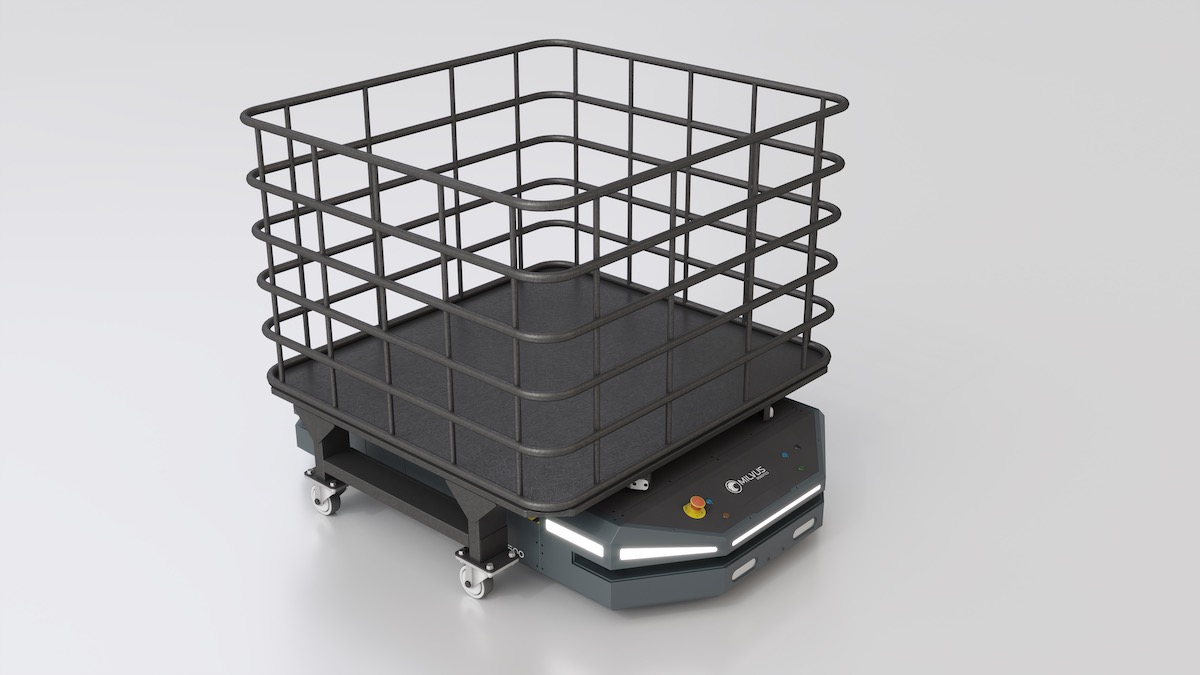

Creates Value

SEIT allows you to reduce transportation related wastes, or in other words, non-value adding operations. Through reorganizing the movement on the production and manufacturing site, it guarantees an efficient and consistent delivery of materials –

which in turn, presents you the option to redistribute your workforce within value-creating roles if desired.

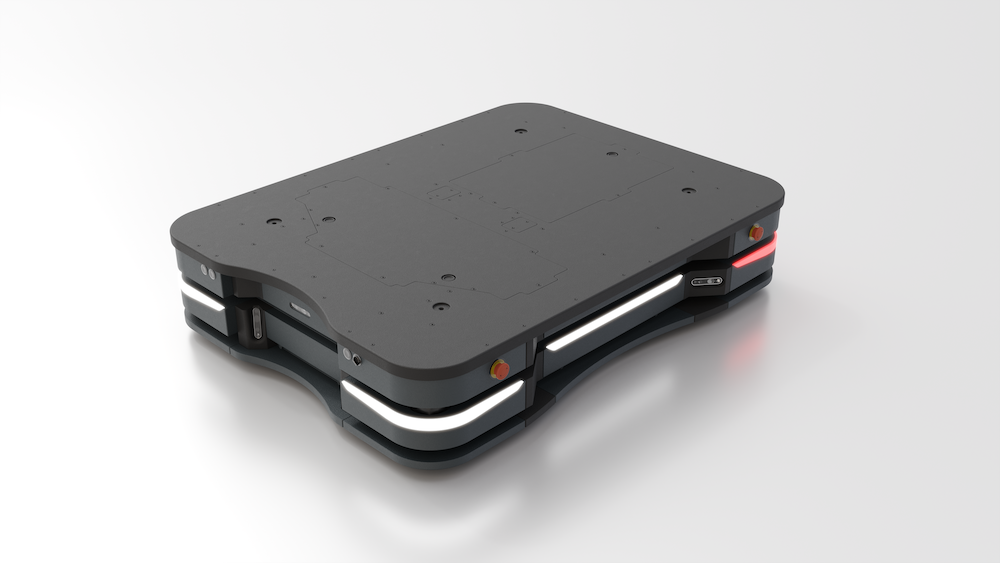

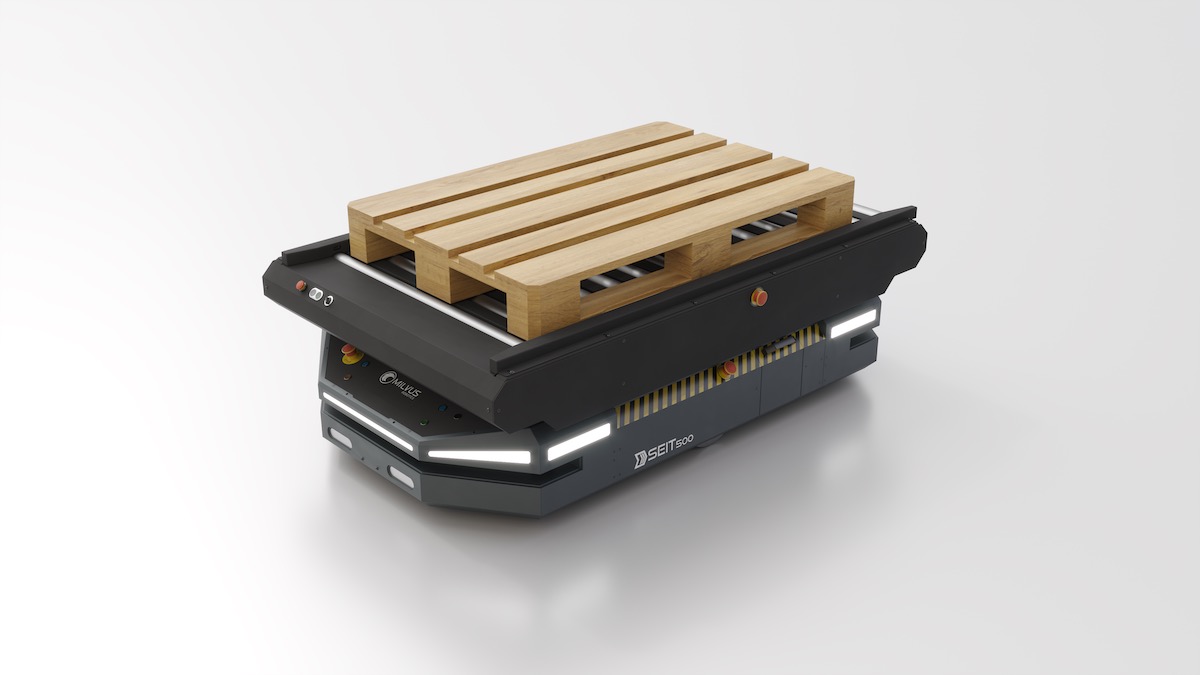

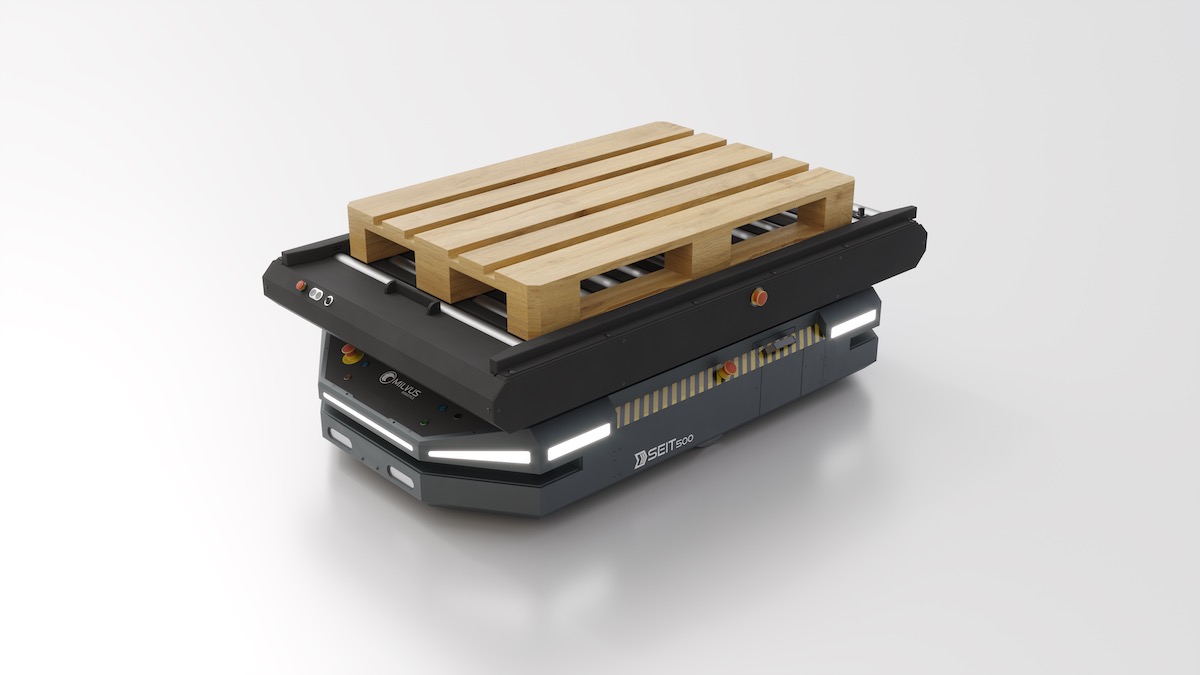

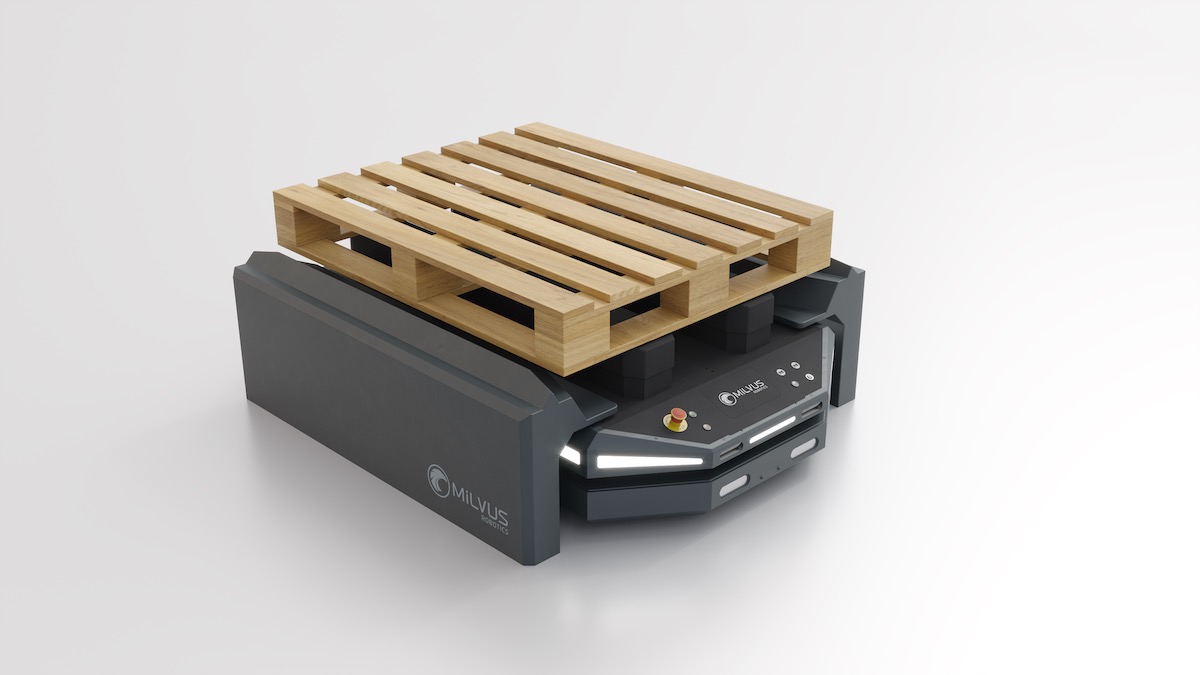

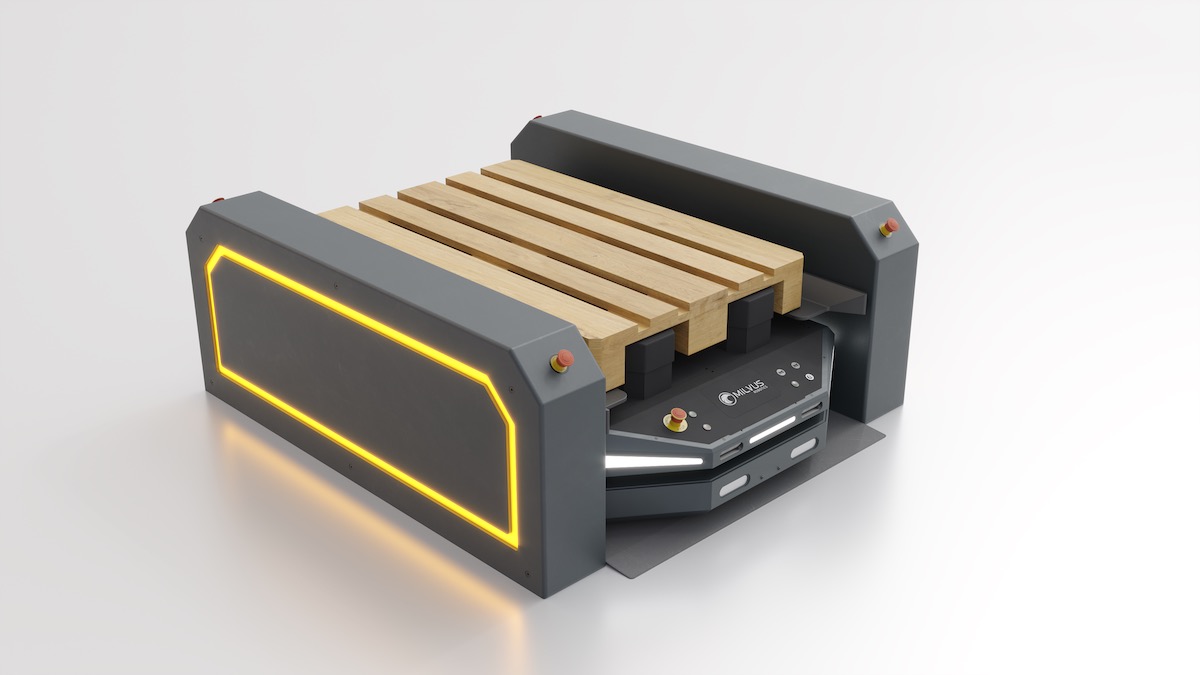

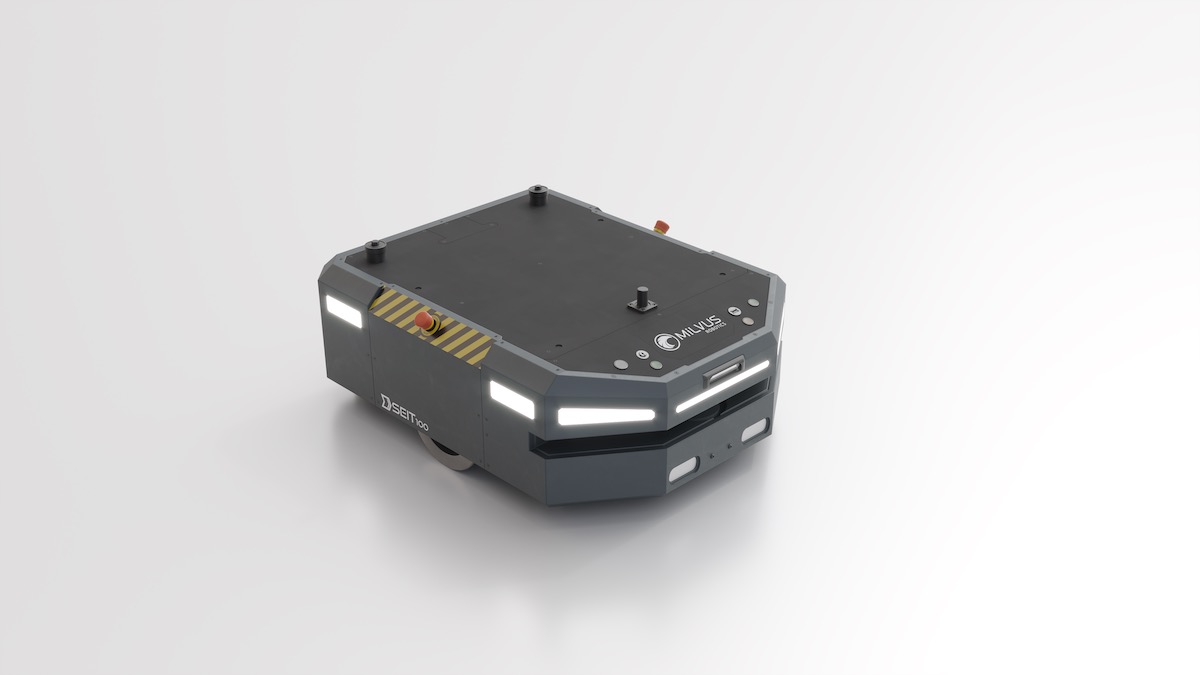

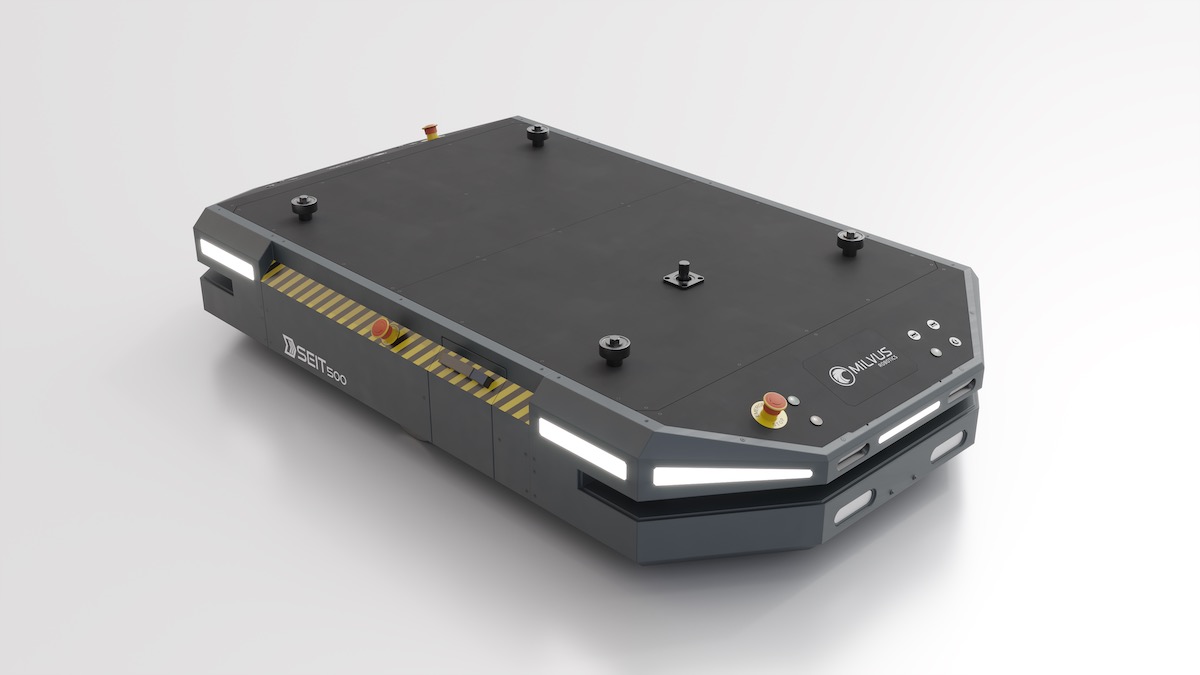

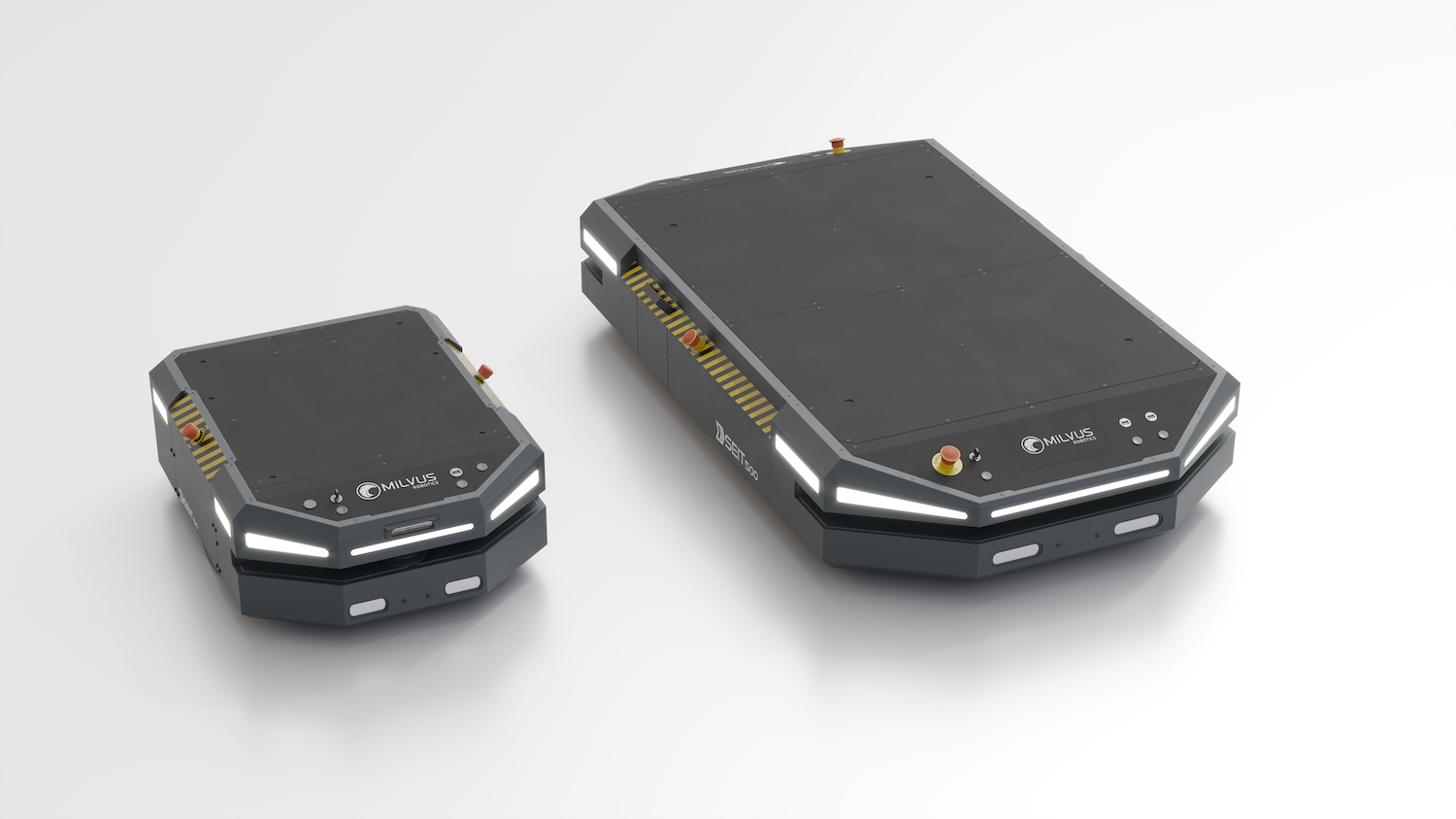

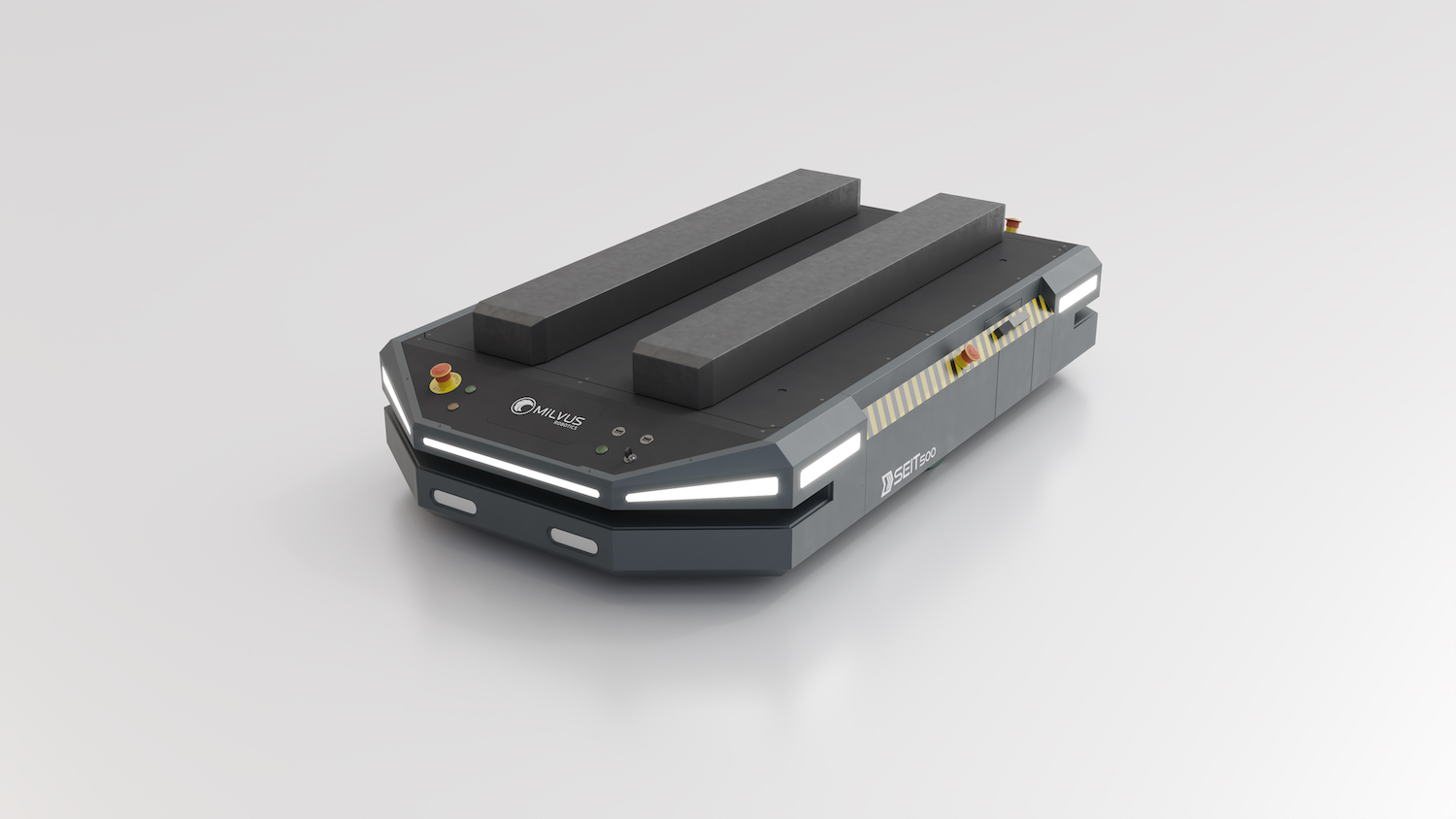

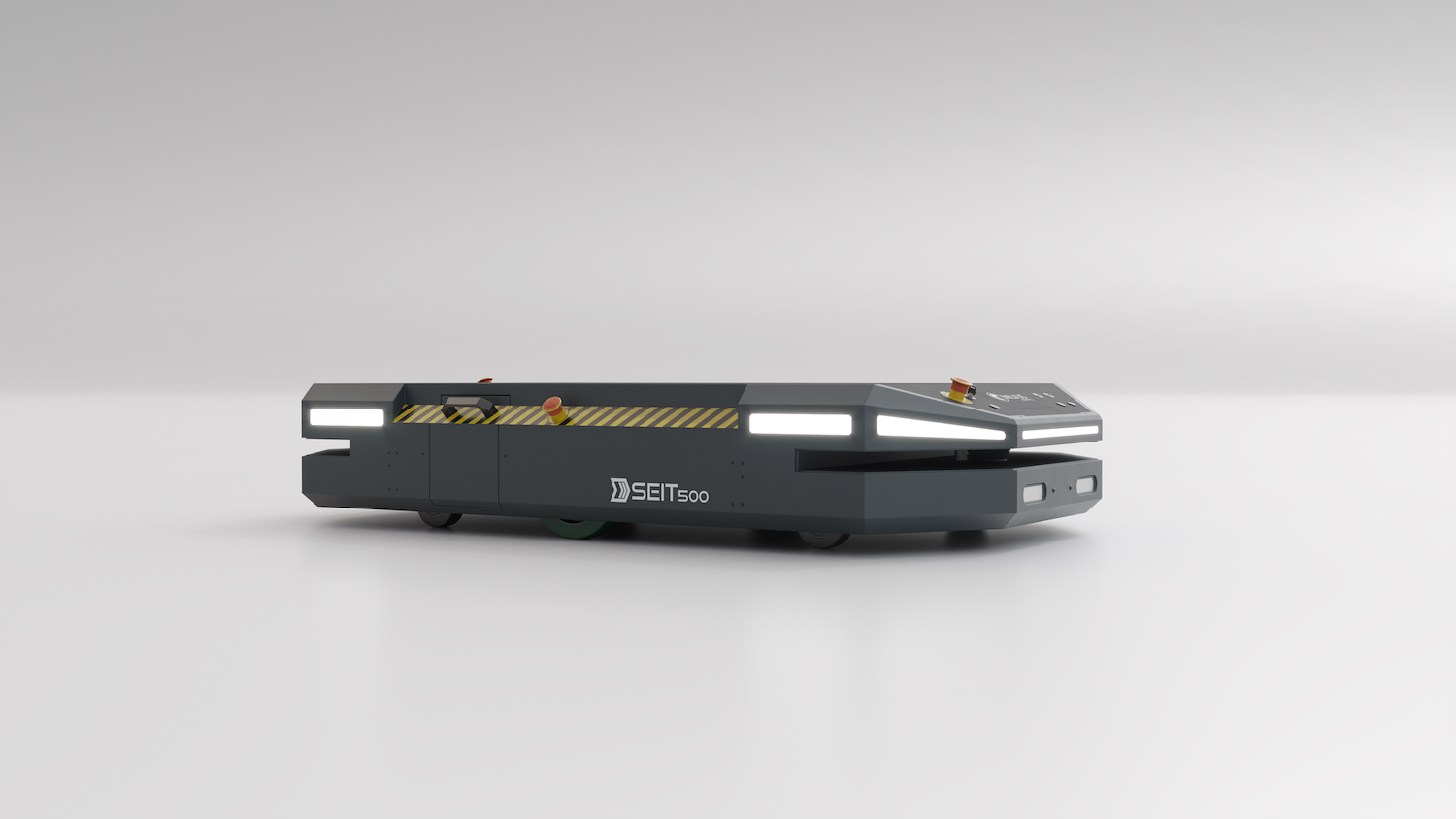

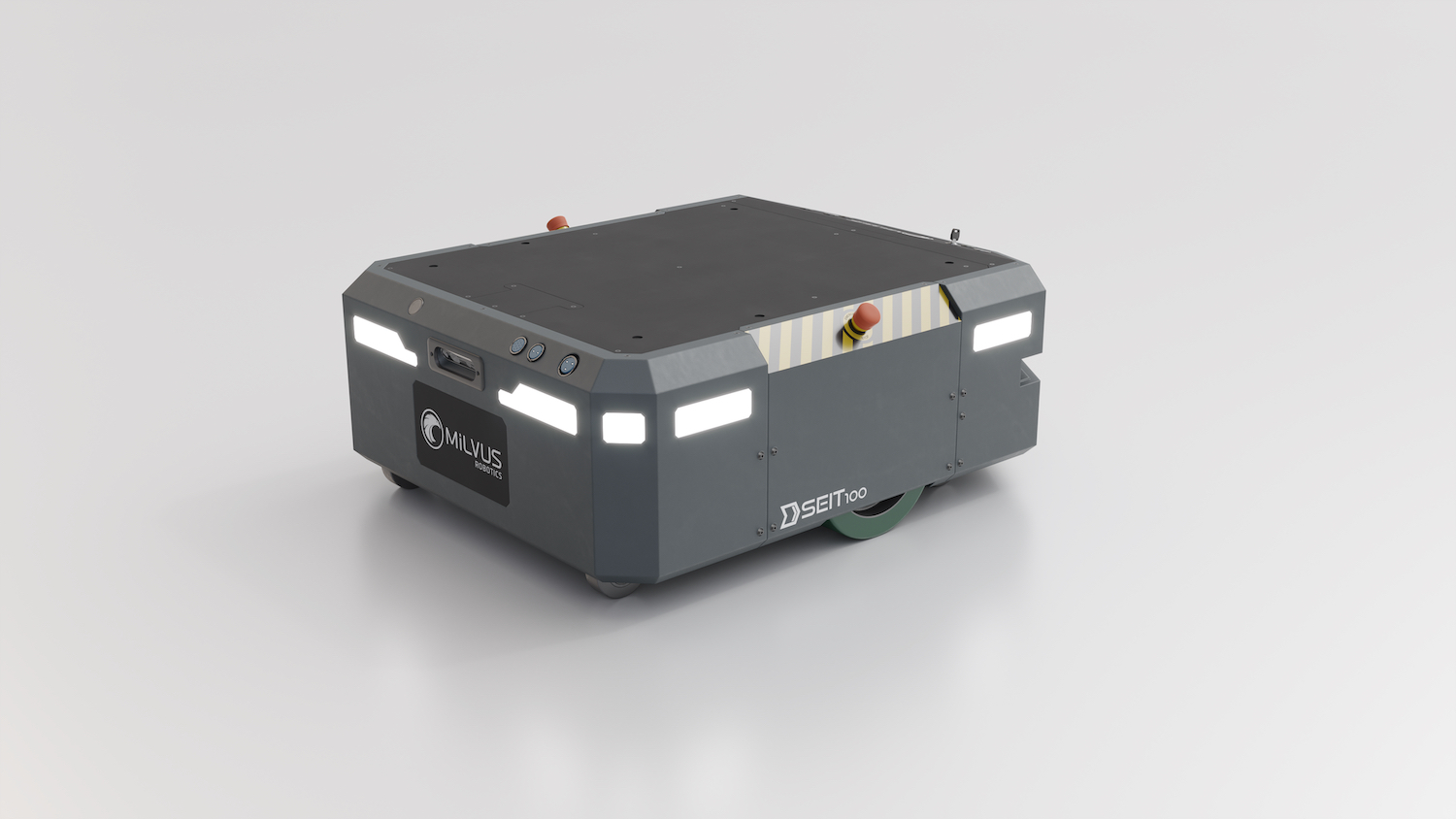

Durable and Strong

SEIT is designed to withstand heavy loads, undertake most arduous tasks and work under harsh environmental conditions. Capable of carrying loads up to 500 kg, SEIT is built with industry standard components that are highly durable and reduce

maintenance costs drastically.