LINAK offers easy integration with robotics applications through CANOpen. Our DC actuators match up with battery voltage to provide the complete linear motion system.

Actuator Technology in Robotics Applications

Actuator Technology in Robotics Applications

Q&A with Anthony Fossaluzza | LINAK Actuators

Tell us about yourself and your role with LINAK.

My name is Anthony Fossaluzza, I’ve worked at LINAK as an Application Engineer for five years. I work with customers in the construction, bulk handling, industrial automation and robotics industries to find the best LINAK actuator for their application.

My name is Anthony Fossaluzza, I’ve worked at LINAK as an Application Engineer for five years. I work with customers in the construction, bulk handling, industrial automation and robotics industries to find the best LINAK actuator for their application.

How does LINAK fit in to the robotics industry?

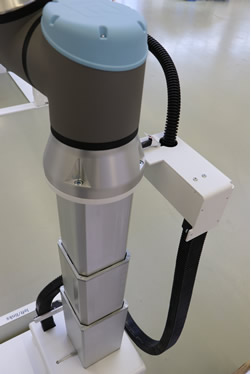

LINAK provides electric linear movement that can extend or add movement to robotics equipment or can replace pneumatics and hydraulics in certain applications.

What sort of robotics applications are you seeing LINAK actuators being used in?

Our lifting columns can be added to cobots to extend their reach. LINAK actuators can be used in small scissor lifts and to adjust forks on forklifts. Our actuators can also be found on lifting robots such as the Scallog system for lifting heavy shelves.

How does the LINAK technology benefit these robotics applications?

LINAK offers easy integration with robotics applications through CANOpen. Our DC actuators match up with battery voltage to provide the complete linear motion system. LINAK actuators are IP rated and tested to operate in industrial environments.

What makes LINAK actuators different than other actuators?

All of our actuators are custom built for each application. Our sales and engineering teams take the time to build the best actuator for your application. Nothing we make is cookie cutter, therefore our customers receive exactly what they need with sales and engineering support throughout the process.

What trends have you seen from attending recent industry events?

There is a major push for companies to be more automated. This can be challenging to do so in existing equipment without having to incorporate multiple components and technologies. LINAK actuators are a complete linear motion system that can easily be integrated into existing equipment to automate it.

Our customers want to quickly move from prototype to production, and we’re able to meet that requirement.

What do you think the robotics industry will look like in five years?

Unfathomable, things are changing so quickly, it’s hard to even guess what it will look in one year.

Click here to learn more about LINAK actuators and their use in the robotics industry.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product