Similar to UPC, Radio Frequency Identification (RFID) has had delayed acceptance in the industry. Patented in 1983, initial RFID research completed in Los Alamos during the 1970s has seen limited acceptance.

The Benefits of Radio Frequency Identification (RFID)

The Benefits of Radio Frequency Identification (RFID)

Scott Moon | Tompkins International

Each year the National Retail Federation (NRF) publishes the shrinkage realized within the all aspects of the retail industry. With shrink consistently hovering around 1.4%, tightening margins require that retailers become more creative to sell enough goods to cover this loss. When you apply this percentage against the industry revenue, what appears to be a manageable number equates to an estimated $46.8B in 2018.

Background

The initial great breakthrough came from Norman Joseph Woodland and Bernard Silver (US Patent 2,612,994) filed in 1952 that used a Morse code of thin and thick bars to code data. It took another twenty years before the Wrigley Company created a Universal Product Code (UPC) in a grocery application to take this technology and launch it into what it is today.

By creating a way to collect a specific item identification by a quick scan, inventory control became efficient. The days when the shop keeper would walk around with a physical stock ledger and count the items he owned versus what he physically found could now be done electronically and with ease. This single invention revolutionized how inventory would be managed.

Today’s Paradigm

The eCommerce revolution is putting tremendous pressure on “traditional” retail to manage tight margins in a marketplace where loss is a profit draining anchor. Despite this drain, we have done little other than sensor tags on an item that are removable to stop this loss. These temporary tags are easily defeated leaving the retailer with labor and cameras as their only line of additional defense.

The Next Generation

Similar to UPC, Radio Frequency Identification (RFID) has had delayed acceptance in the industry. Patented in 1983, initial RFID research completed in Los Alamos during the 1970’s has seen limited acceptance.

Since its inception, the size of an RFID tag has reduced coupled with more powerful reading devices advances has positioned the RFID technology ready for prime time. Retailers and manufactures must strategically work together to integrate tags into products that ensure the tag removal defaces the product. Once accomplished, inventory control will take its next big step in providing strong oversight and control.

The Economics

Realizing this approach will be based on the cost to integrate tags into garments, the industry must drive prices to a reasonable level where it costs pennies and nickels to make it happen. The higher the loss one wants to remove, the higher average cost needs to be to be able to afford the tag cost.

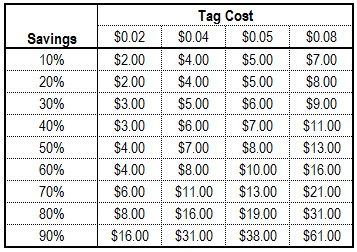

The Item Cost that Delivers the Savings Target Covering the Tag Cost

For tags to be applicable to any items, the cost of the tag must be one cent or less. In the chart above, it shows the cost of the item within the matrix. If the tag cost two cents and you wanted to reduce the shrink by 10%, the cost of the item would need to be two dollars or more to deliver on the requirement. Similarly, if the tag cost eight cents per tag and you wanted to deliver 30% in loss reduction, the item would need to cost nine dollars or more for RFID to be of value.

No longer do you need cameras and staff to watch for shoplifters. You merely need to arm the door with an RFID sensor and it will capture the offender. Further, shoppers could be identified upon entry and any removed item automatically charged upon exit. Check-out labor can be greatly reduced and staff can focus on selling rather than clerical activities.

What Did the Customer Touch/Review?

With RFID retailers can track items that moved from the shelf. They can see what customers looked at and inspected. This will help them better understand items of interest.

If touches decline, retailers can quickly recognize a “poor” assortment and mark it down immediately. They could also see high desired items and begin to unleash the supply chain to chase additional stock (raw materials and finished goods).

RFID could be the next evolution to not only inventory control but a new science of customer product handling, helping to better understand customer interest and desires.

Summary

Retail is caving under the weight of margin pressures. It’s time for the industry to take control of shrink/loss and unleash the power of RFID technology and leverage it to understand customer touches and how it forecasts revenue. By doing so, the burden that brick and mortar in fixed cost could become a competitive advantage to understand true customer desires that eCommerce now leverages to understand customer interest. A physical touch (fabric, color, style) review from a customer tells more about the products desire than an online click.

Traditional retail has the benefit of enabling real-time consumption and satisfaction while in the store. It’s time traditional retail evolves how it views customer traffic and repositions it to their advantage. Instead of worrying about clerical activities, store staff can get back to understanding their customer and deliver true customer service.

The applications are endless. Whether indoors or out, in a mobile van or in a store, RFID is ready to meets today’s needs in any application.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product