Booth #6773 - This year’s show will be an importing stepping stone into our next chapter as we rapidly expand our distributor network and market traction.

Contributed by | OnRobot

Tell us about your company.

OnRobot is the global leader of end-of-arm-tooling for collaborative robot applications. Established in 2015, OnRobot merged with Perception Robotics and OptoForce in 2018, followed by a recent acquisition of Purple Robotics. Our product range now features a wide assortment of robot equipment, including: electric grippers, force/torque sensors, gecko grippers, and tool changers. This new combination of offerings makes it quicker and simpler to automate tasks such as packaging, quality control, materials handling, machine operation, assembly, and welding. Headquartered in Odense, Denmark, our North American office is located in Dallas, TX. We also have offices in Germany, China, Malaysia, and Hungary.

Your company will be exhibiting at AUTOMATE, what is it that makes this an important event for your company?

This is our second showcase at Automate, our debut in 2017 helped facilitate our entry into the U.S. market, paving the way for crucial new customer and sales partner relationships. This year’s show will be an importing stepping stone into our next chapter as we rapidly expand our distributor network and market traction.

What makes your booth a must visit for AUTOMATE Attendees?

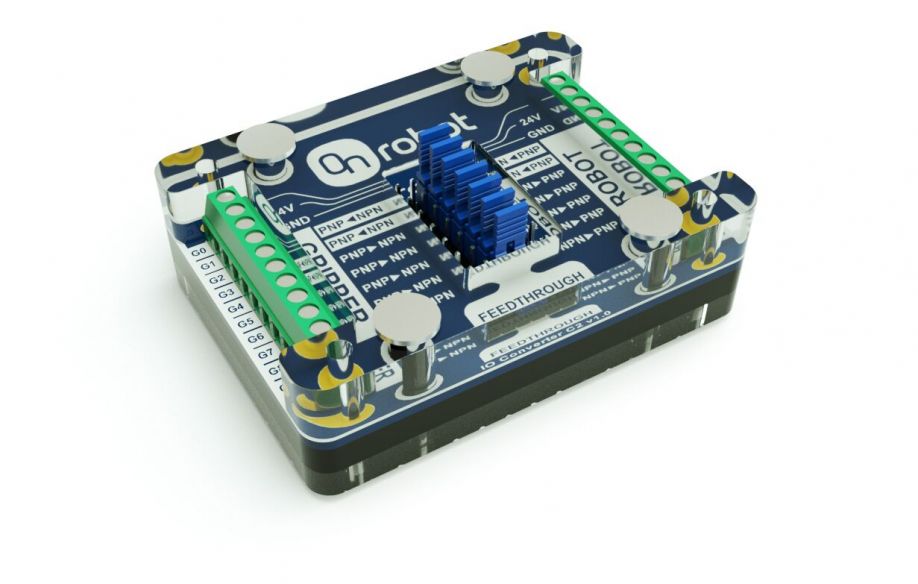

Integrating grippers with robot arms is often one of the biggest headaches when developing new robotic applications. A major obstacle is mismatched I/O signals between the end-of-arm-tooling (EOAT) and the robot arm. To address this challenge, we’re Iaunching the new Digital I/O Converter Kit at our Automate booth. The converter supports seamless integration of our RG2, RG6, Gecko, and VG10 grippers with a wider range of both collaborative robots (cobots) and traditional robotic arms, such as KUKA, FANUC, Yaskawa, Kawasaki, Doosan, Nachi, and Techman models. Our mission is to facilitate faster deployment of collaborative applications, the converter is an important piece of that puzzle. We look forward to showing the improved compatibility to our booth visitors.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

OnRobot end-of-arm tooling is now increasingly showcased in other Automate booths as well where our OEM partners chose our EOAT for their own automated solutions. We look forward to walking the show floor, witnessing our products in action all over McCormick Place.

Give us your thoughts on what the future holds for manufacturers and automation technology.

Collaborative robots are now the fastest growing segment of industrial automation, expected to grow ten-fold by 2025. The cobot arm, however, is fast becoming a commodity as real innovation now happens in the EOAT realm. Our goal is to be the cobot one-stop-shop solutions provider for all EOAT products.”

If you would like please provide contact information for a reader to setup a booth demo.

To setup an appointment for a booth demo or visit, please contact: sales@onrobot.com

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product