Stäubli’s MPS tool changer provides JAC with flexibility and minimal technician intervention during the manufacturing process, particularly during the handling and welding processes. Water, air and electrical circuits can be connected and disconnected simultaneously.

Chinese cars in motion thanks to Stäubli connectors

Case Study from | Staubli Corporation

THE PARTNER

Jianghuai Automobile Group Corp., Ltd. (JAC) is a Chinese auto manufacturer that produces its own line of commercial vehicles, vehicles for public transportation and alternative energy vehicles, and also develops gearboxes and engines.

APPLICATION

Manual or automatized connection of all fluid and electrical energies on the assembly and production lines as well as for cold or hot engine tests.

The challenge

With an annual output of 1 million units, JAC needed connection and tool changing solutions that offered the utmost efficiency, dependability and durability in their manufacturing process – particularly during assembly and testing processes.

“The maintenance procedures of Stäubli products are very easy. Their durability allows us to significantly reduce our operating costs."

Kanghe Yang, Engineer

The solution

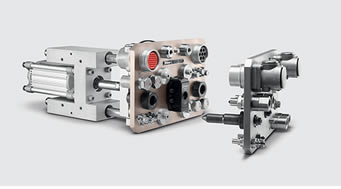

Stäubli’s Multi-Coupling System (MCS) provided JAC with a safe and reliable connector solution, customized for their needs. With MCS, different energy sources can be connected by a single motion at a single point. During the assembly process, the MCS is used to connect all fluid and electrical circuits. Stäubli’s MPS tool changer provides JAC with flexibility and minimal technician intervention during the manufacturing process, particularly during the handling and welding processes. Water, air and electrical circuits can be connected and disconnected simultaneously.

Stäubli solutions are also integrated during cold and hot testing phases. Designed to meet the customer specifications, the dedicated mono couplings RPE are used to connect the engine plug profile and for the connection of all fluid circuits between the test bench and the engines. JAC used standard Stäubli quick-release couplings. Manual or automatic MCS are utilized once again in the testing phases for the simultaneous connection of all fluid and electrical circuits (water, oil, air, signal and power).

The result

Stäubli’s quick couplings, MCS and MPS systems have made JAC’s manufacturing process more efficient and reliable. Due to the low maintenance required to maintain these systems, JAC has been able to significantly lower its operating costs, optimized their facility’s efficiency and improved productivity.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Staubli Corporation

Stäubli is a leading manufacturer of textile machinery, quick release couplings and robotics systems. With a workforce of over 4500 employees Stäubli is present in 25 countries supported by a comprehensive distribution network in 50 countries worldwide. Stäubli's North American headquarters is located in Duncan, South Carolina and has over 200 employees supporting Textile, Connectors and Robotics customers, with a dynamic sales force strategically placed on the West Coast, Canada, Mexico, and elsewhere throughout the continent.

Other Articles

Multi-couplings reduce down time and improve efficiency

Talking AUTOMATE 2023 with Stäubli

Talking Automate 2022 with Stäubli Group

More about Staubli Corporation

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product