3D printing is not the miracle we were promised

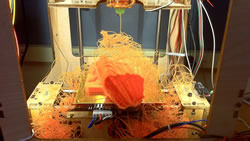

Mike Murphy for Quartz: 3D printing has been hailed as the future of manufacturing for years now. Consumers and investors were sold on the idea of being able to print anything at any time from a little box in their houses. But that Jetsons-like vision hasn’t come to pass. The 3D printers available to consumers are great for making small prototypes or tchotchkes. But they’re still slow, inaccurate and generally only print one material at a time. And that’s not going to change any time soon.

Mike Murphy for Quartz: 3D printing has been hailed as the future of manufacturing for years now. Consumers and investors were sold on the idea of being able to print anything at any time from a little box in their houses. But that Jetsons-like vision hasn’t come to pass. The 3D printers available to consumers are great for making small prototypes or tchotchkes. But they’re still slow, inaccurate and generally only print one material at a time. And that’s not going to change any time soon.

That reality is setting in for 3D printer makers. Stratasys, which owns MakerBot and is one of the world’s largest manufacturers of commercial and industrial 3D printers, announced its fifth straight quarter of losses today. 3D Systems, which was founded by the man who invented 3D printing—Chuck Hull—isn’t faring much better.

Wall Street’s interest in 3D printing seems to have peaked in the first week of 2014: The stock prices for both Stratasys and 3D Systems were at their highest on January 3 last year. Stratasys had completed the purchase of MakerBot—which has been called the “Apple” of 3D printing—about three months earlier, and it looked as if things were on the up. But a little over a year later, MakerBot laid off a fifth of its staff, closed its stores, and started focusing on selling to schools.

As it stands, it seems that the market is retracting to industrial printers, for companies that benefit from rapidly prototyping objects. 3D printing makes a lot of sense when companies can quickly model and print their ideas—anything from new bike helmets to car doors or sprockets. These are where (relatively) cheap, disposable plastic models thrive, as companies can churn out all the models they need, and then turn to more traditional automated processes, like CNC milling or vacuum forming, to build their final product at scale, using materials that will actually last. Cont'd...

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product