Why Everyone Must Get Ready For 4th Industrial Revolution

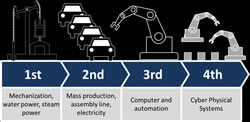

Bernard Marr for Forbes: First came steam and water power; then electricity and assembly lines; then computerization… So what comes next?

Bernard Marr for Forbes: First came steam and water power; then electricity and assembly lines; then computerization… So what comes next?

Some call it the fourth industrial revolution, or industry 4.0, but whatever you call it, it represents the combination of cyber-physical systems, the Internet of Things, and the Internet of Systems.

In short, it is the idea of smart factories in which machines are augmented with web connectivity and connected to a system that can visualize the entire production chain and make decisions on its own.

And it’s well on its way and will change most of our jobs.

Professor Klaus Schwab, Founder and Executive Chairman of the World Economic Forum, has published a book entitled The Fourth Industrial Revolution in which he describes how this fourth revolution is fundamentally different from the previous three, which were characterized mainly by advances in technology.

In this fourth revolution, we are facing a range of new technologies that combine the physical, digital and biological worlds. These new technologies will impact all disciplines, economies and industries, and even challenge our ideas about what it means to be human. Cont'd...

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product