A classic problem in engineering is the rotational inverted pendulum. It is used to demonstrate and examine movement patterns and control algorithms in control and electrical engineering as well as in mechanical engineering. These help to control robots and other machines.

MiniMACS6 Stabilizes the Furuta Pendulum

Article from | maxon group

The pendulum, named after its Japanese inventor Katsuhisa Furuta, has a simple structure. A driven arm rotates in the horizontal plane and a pendulum attached to that arm rotates in the vertical plane. Theoretical modeling and the need to stabilize these movements are issues that have long racked the brains of engineers. With the Furuta pendulum, there are two variables: the direction of the rotational joint and that of the pendulum, which can be controlled. The pendulum is controlled in the vertical, unstable position, while the arm assumes any position. Since it is a nonlinear, unstable system, it is suitable for conducting experiments, for testing existing control algorithms, and for developing new calculation methods. It frequently combines approaches from research areas such as robotics, control theory, and computerized control.

Finding the right controller

A suitable controller can be developed using different design strategies. Suitable controller structures for an inverted pendulum include PID, LQR, fuzzy, or self-learning neural controllers. The physical system with multiple degrees of freedom can be modeled mathematically. For the swing-up of the pendulum from the rest position (zero position), nonlinear approaches such as energy approaches are required. A suitable controller is then designed with the help of the mathematical description. This controller can be approximated or discretized for real-time-capable systems and transferred to a controller such as the MiniMACS6-AMP4.

The compact controller

The maxon MiniMACS6-AMP4 is a programmable master controller with integrated power stages. It is the stabilizing controller for the rotational inverted pendulum. This allows complex movement patterns to be executed with simple commands, for example for jerk-free synchronization with a rotating master axis. Benefits of the MiniMACS6-AMP4 multi-axis controller:

- Assumes the master function; no higher-level controller required

- License-free motion control functionality included

- Compact drive solution with integrated power stages

The license-free automation software ApossIDE (Integrated Development Environment) can be used to set up positioning and synchronization tasks with simple commands or you can run your own control algorithms using C (ApossC).

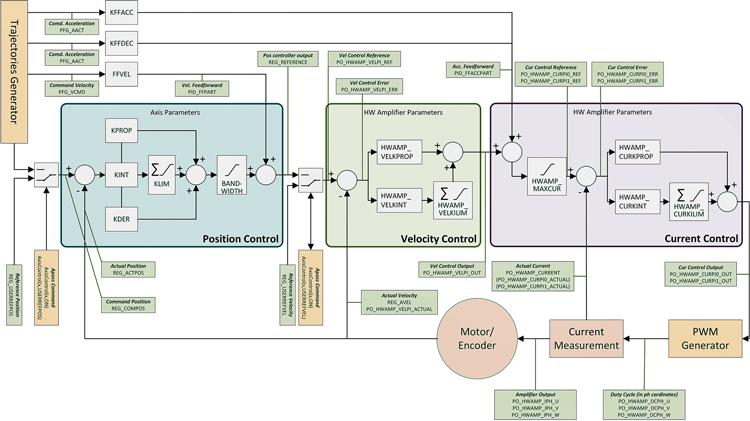

Cascade control

In action: The MiniMACS6-AMP4 stabilizes the rotational inverted pendulum.

COMPACT MiniMACS6-AMP4 multi-axis controller

The programmable multi-axis controller with integrated power stages is the stabilizing controller for the rotational inverted pendulum and ensures jerk-free synchronization with the rotating axis.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

The rise of modular robots and the importance of drive train design

Optimizing Material Handling Processes for Increased Efficiency

200 Times Faster Subsea Inspection

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product