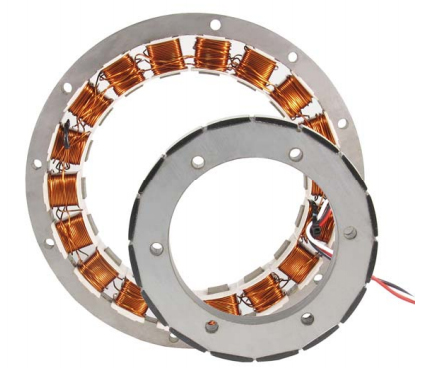

Integrated Wheel Drives for Electric Utility Vehicles

Well look at electrically-powered vehicles in this load class of about 100 lb (45 kg) up to 2,000 lb (900 kg), and in particular the types of propulsion systems used in them, including fully integrated traction drive systems.

Gigabit Ethernet Interfaces and Robotics: John Phillips, Pleora Technologies

Were seeing growing demand for interfaces that dont require a traditional frame grabber inside the personal computer (PC), as well as a migration towards smaller form factor PCs with embedded processing.

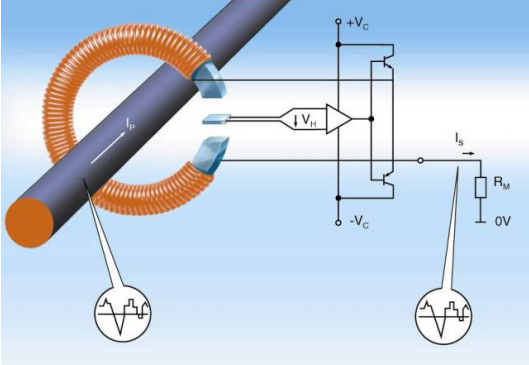

Closed Loop Current Transducer Characteristics

A properly selected current transducer for an application can easily give 25+ years of service. By acknowledging the details behind the data sheet, better performing applications and more robust designs are possible.

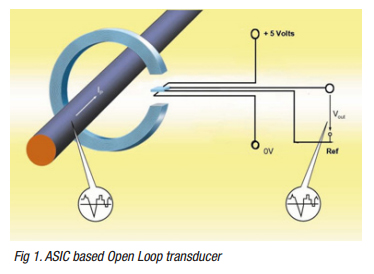

ASIC Based Current Transducers

The implementation of ASIC based current transducers opens up functionality that the traditional discrete component transducers could never achieve.

Flexible Seals for Robotics Systems

The Roxtec system is based on a rubber-sealing module that consists of two halves, a center core, and removable black and blue layers. This construction ensures adaptability to different sizes of cables and pipes.

Face of the Future

Micro drives gives humanoid service robots human traits.

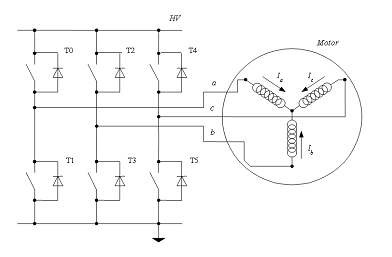

Precise Brushless Torque Control With Only 1 Shunt Resistor

The circuitry to sense precisely the current of three windings of a motor adds a significant space and cost to an electronic board. For that reason, new control algorithms are being developed to work with only one shunt.

Application Case Study: Continental AG, Czech Republic Division

Smart Cameras Provide Additional Benefits to Auto ID Applications

Records 16 to 23 of 23

Featured Product

NVIDIA RTX PRO BLACKWELL DESKTOP GPUs

NVIDIA RTX PRO - Built for Professionals - NVIDIA RTX PRO Blackwell Desktop GPUs feature the latest breakthroughs in AI, ray tracing, and neural rendering technology to power the most innovative workflows in design, engineering, and beyond.

Robotics and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.

.jpg)