A Cut Above: Adding Next-level Protection for Next-generation Welding

By partnering with Roboworld since their first Cobot rolled off the line on Day 1, all of Vectis' robotic welding systems and teach pendants have included Robosuits® and Pendant Armor®.

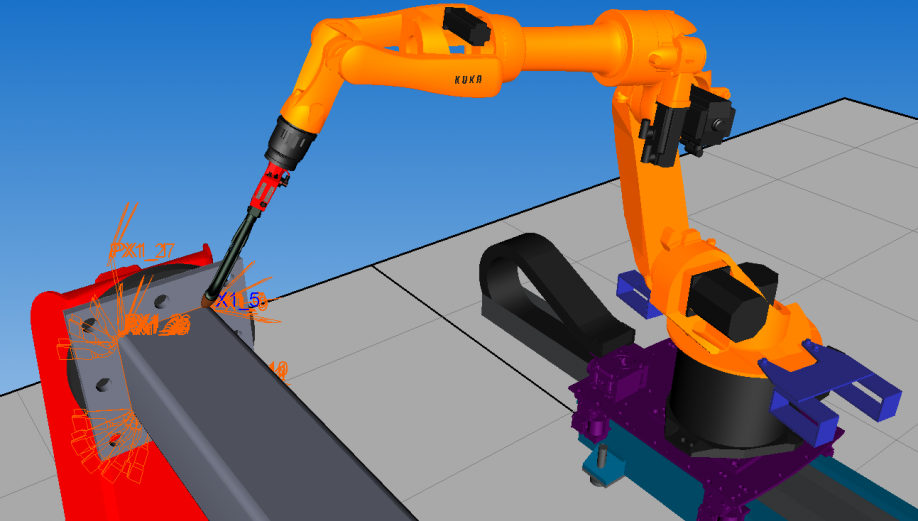

Sustainable Industry Repair using RoboDK

The purpose of the project was to improve laser welding procedures and determine if sustainable gear repair was possible using robot toolpath programming, digital twin, simulation, and post-processing.

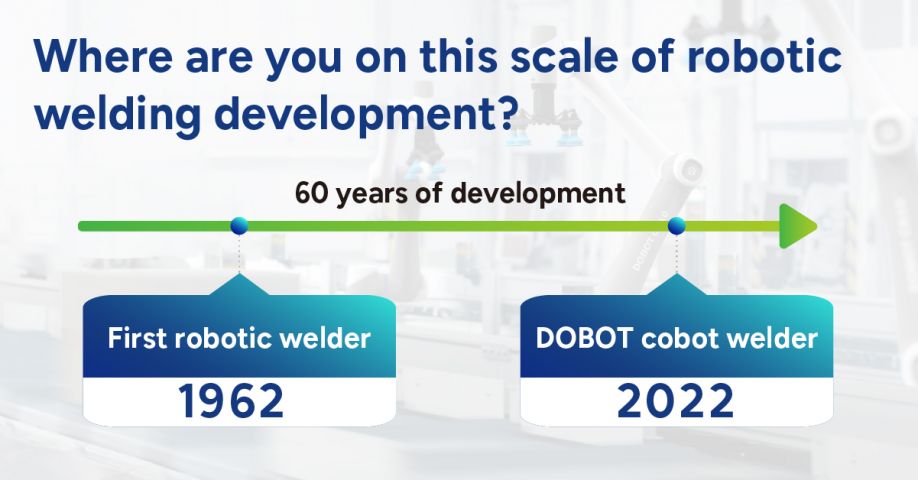

Robotic Welding on a Way to Automation

As the time comes by, the role of robotic welders is growing. To step up into Industry 4.0 and head into Industry 5.0, more and more manufacturers are applying the concepts and principles of automated welding.

Robotic Welding Trends for 2022

Like most manual and fabrication processes in the digital age, welding has been enhanced and improved by technological concepts such as automation in recent times.

Three Reasons to Robotize Soldering Operations

As electronics get smaller and manufacturers come under greater pressure to improve efficiency and throughput, the traditional hand soldering method is no longer up to scratch.

Emerging Applications for Robotics in the Aerospace Industry: 5 Innovations

The aerospace industry is constantly evolving, and modern robotics are driving that change. The last several years have seen significant growth in robotics, with much of it concentrating on industrial applications for the aerospace manufacturing process.

Could Cobots Be the Answer to the Welder Shortage?

The American Welding Society has predicted a deficit of 400,000 welders by 2024. According to specialist welding technologists K-TIG, a US welder's skills are in such high demand they can demand a salary of $100,000.

Boyce Technologies designs and mass produces FDA-approved ventilators in just 30 days

ABB assists Boyce to repurpose their advanced manufacturing facility, enabling them to make 3,000 ventilators in record time for New York hospitals.

FANUC Introduces Collaborative Arc Welding Robot at FABTECH 2019

FANUC's new collaborative arc welding robots offer the same high level of performance that FANUC ARC Mate robots are known for including world-renowned technology and proven reliability.

Acura Provides All Access Look into the Performance Manufacturing Center (PMC)

"Inside PMC" is an all-access pass to one of the world's most advanced manufacturing facilities and home of the second-generation Acura NSX supercar

RoboticsTomorrow - Special Tradeshow Coverage

FABTECH 2018

FABTECH takes place in Atlanta, GA November 6th - 8th. This RoboticsTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

Shortage of Professional Welders Leaves Room for Robots in the Field

It seems likely robots will continue to be instrumental in helping companies cope with the persistent welding skills shortage. This is a strong example of how technology can assist with overcoming factors that cant always be easy to control or solve.

Robotic Welding 101

Robotic welding design from the ground up.

Welding With OCTOPUZ

In a continuing series, OCTOPUZ will be showing their expertise in the field of offline programming software for robotics. In this article, we will be examining robotic welding.

Robotmaster Reduces Outsourcing, Increases Production and Profitability

Adding a robotic system enabled Groupe Gravel, a metal fabricator, to profitably automate cutting and welding for high-mix short-batch production. Robotmaster's tools enabled automatic path creation from CAD models drastically improved programming time.

Records 1 to 15 of 18

Featured Product

ATI Industrial Automation - Manual Tool Changers

Simpler, stronger, and more precise. ATI Industrial Automation has developed a series of Manual Tool Changers that provides a cost-effective solution for quickly changing tools by hand. They feature a unique design that combines high strength, excellent repeatability, and a patent-pending screw-cam locking mechanism with multiple fail-safe features, which resists vibration and prevents loosening. These robust and compact Manual Tool Changers can handle payloads up to 80 pounds (36 kg) and pass pneumatics and electrical signals.

.jpg)