Drones will eventually be “as ubiquitous as pigeons”, London-based futurist Liam Young recently predicted. They will be used for a lot of different tasks. One overlooked drone application even has the potential to become a trillion dollar business. And to save the world.

Udo Zillmann | Daidalos Capital

As ubiquitous as pigeons

Drones will eventually be “as ubiquitous as pigeons”, London-based futurist Liam Young recently predicted. They are omnipresent already. Only 5 years ago drones belonged to the realm of the military, unaffordable for anyone else. Today, they are for hobbyists and even kids. Drones arrived in our lives and conquered the extreme ends of the market for technical goods. They proved to provide the best value for both, defense budgets and pocket money. Now the race is on to fill the gap in the middle: startups, corporates and analysts try to find the most promising commercial applications for drones. That is quite a challenge since drones can be used for a surprising variety of tasks. Much media attention was paid to Amazons’, Google’s and DHL’s announcement of using delivery drones. Others see the future for drones in surveillance, detecting fires, cracks in pipelines or illegal wood logging. They can also monitor farmland in detail for precision farming. Or communication: autonomous solar powered drones can be used to hover at high altitude over an area for months to provide wireless communication similar to a satellite. Facebook and Google have invested in startup companies in this field. But there are other disruptive uses for drone technology which the current debate is largely unaware of.

One example is Elon Musk and his SpaceX company. He is working at landing and later reusing Falcon rockets after they have delivered their payload into space. It is impossible for a pilot to control a precision upright landing of a rocket that literally falls out of the sky. Only cutting-edge drone technology can do the job. If the rocket was to be recycled it would lower the flight costs from the cost of building a rocket to the cost of refueling it. That ist US$ 200,000 instead of US$ 55 million. The business potential for the “rocket drone” would be enormous.

Or take Miles Loyd. In the energy crises of the late 1970s Miles Loyd worked as an engineer at Lawrence Livermore National Laboratory. He attempted to build the best wind generator imaginable.

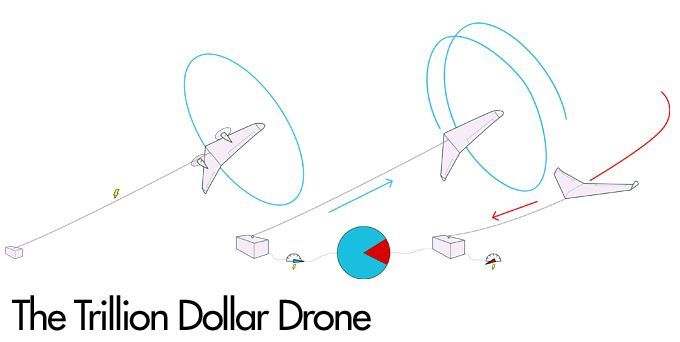

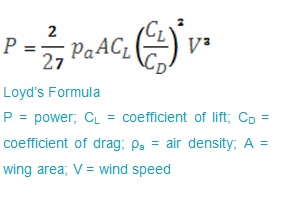

He had the radical idea of building it without a tower, only using a flying wing connected to the ground by a tether, much like a kite. He calculated the expected energy output of his “flying wind generator”. Based on the formula he first established – today known as Loyd’s Formula – he found that a wing with the size, weight and aerodynamics of a standard plane wing of the 1970s could produce 6.7 MW of power. Even larger wings with an output of 45 MW seemed feasible. To put this into perspective: even today, 35 years later, the average wind turbine is still below 3 MW and the largest existing prototype has 8 MW. Loyd obtained a patent and published an article on this new technology.

And here the story ends.

He could not convince investors to finance his flying wind generator, because he had no solution for one problem: how to control the flying wing without a pilot?

Today, we have a technology that lets us control flying objects without a pilot. It is called: drones.

If we can apply this new technology to Loyd’s old formula we can build a new type of drone: the wind drone.

Wind Drone Technology

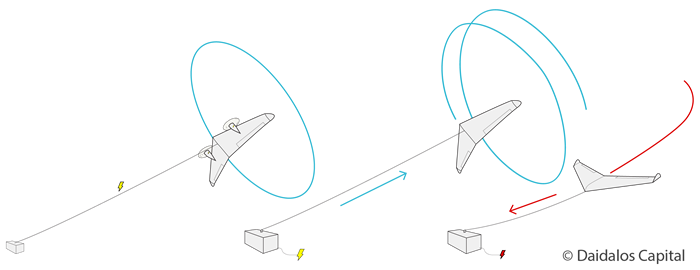

How exactly does a wind drone work? There is a great resemblance to kite surfers. Kite surfers use a kite and a tether to pull a surfer through the water. The same mechanism can be used to generate electricity. The tethered kite or wing is connected to a drum and a generator on the ground and the tether is wound around the drum. The wing tears at the tether and turns the drum to generate electricity. Once the tether is fully unwound, the wing nosedives and the tether is quickly reeled in. Then the cycle starts again. This up-and-down motion inspired the name “yo-yo” type wind drone.

Google X, overseen by Sergey Brin, is working on a different wind drone in its Makani project. Google’s approach is to use little propellers (mini wind turbines) and generators directly mounted on the wing where they produce electricity. An electric cable is woven into the tether and transfers the electricity to the ground. In 2013 Makani presented a working prototype. They already built their first scaled up product with 600 kW output and announced that it will fly in 2015.

Flying wind turbine on the left, "yoyo" on the right

Google will be the first team to show a wind drone with power outputs comparable to today’s wind turbines. But they are not the only ones who have realized that drone technology is ripe to take on Loyd’s formula. Companies including 3M, ABB, Alstom, E.ON, Honeywell, Statkraft and Softbank have conducted research on wind drones and/or financed one of the dozens of airborne wind energy startups worldwide. Some of the prototypes use soft wings resembling a surf kite or a paraglider, others use hard wings like the wing of an airplane. The designs also differ in many other details. A dominant design has not yet emerged. But irrespective of their final design, wind drones share three characteristics that could turn them into the killer application for drone technology: they will disrupt their market, they will be one of the first autonomous drone applications to be market ready and they will have the largest market of all drone applications.

Disrupting the Market

Producing wind energy is not a new idea and we already have a tried and trusted device for this task: the wind turbine. Wind drones will have to offer significant advantages over wind turbines to conquer this market. Airborne wind energy companies claim that wind drones can be built at half the price of wind turbines. In addition, they claim that downtimes for wind drones will be significantly lower and wind drones therefore produce twice as much energy with the same rated power. According to their calculations energy from wind drones could therefore be available at just one quarter of the price of energy produced by wind turbines. But are such claims realistic?

Costs

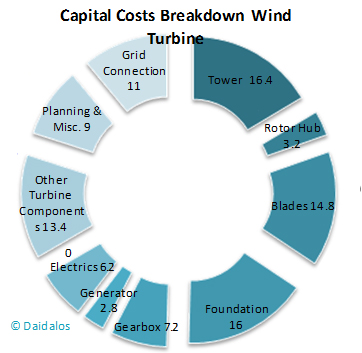

Can you manufacture wind drones more cheaply than wind turbines? The capital costs of a wind turbine which make up the bulk of the total costs of wind energy are the following:

The structural elements, the tower, the blades, the foundation and the rotor hub make up half of the total capital costs of wind turbines. Material requirements are extremely high: Up to 700 tons of steel for the tower, another 100 tons of steel for the rotor hub, up to 100 tons of glass-fiber reinforced plastic for the blades, and up to 4000 tons of concrete for the foundation.

Wind drones lack theses massive structures. The tower is replaced by a thin tether. A wind drone with the power of the largest existing wind turbine (8 MW) requires a tether that is 2.5 inches/6 cm thick and would weigh less than one ton. Only minimal foundations are required and the wings can be much lighter requiring only 1 to 10% of the material of the blades of a wind turbine. The Google Makani 600 kW wing weighs below 2 tons including the tether and generators on board. A comparable 600 kW wind turbine weighs between 50 and 100 tons without foundation.

The required components for power generation are cheap in comparison: the costs for the electricity producing generator amount to less than 3% of total costs. Certainly, wind drones will need more and better sensors, processors and other control components, but these cost much less than the saved materials.

Stop Building Lever Arms

How can a wind drone save half the costs of a wind turbine? It is all about physics. A basic construction principle in engineering is to avoid a 90° force on an unsupported lever arm wherever possible. Large bridges are therefore supported by arches, columns, or suspension tethers. If parts cannot be supported they have to be made as short as possible.

Wind turbine engineers have done the opposite. Rightfully wanting to build ever larger and more efficient wind turbines they worked to increase the height of the towers and the length of the blades.

Crazy architecture, routine in wind turbine design: building huge lever arms. Pictures roughly true to scale; unsupported lever: Skywalk Grand Canyon 70 ft/21 m, wind turbine max: 720 ft/220 m (total height), 475 ft/145 m (tower), 260 ft/80 m (blade length)

Both are lever arms in a 90° angle to the wind force and they are not supported. Wind engineers would love to tether the tower and the blades. But it is not possible. The wind can blow from all directions, so the rotor has to be able to rotate around the tower and the blades have to spin freely. Nonetheless, wind engineers have excelled in building ever larger wind turbines. They hold the record for building the longest unsupported lever arms in the world. Undoubtedly a great achievement, but one that does not help saving material. The tether of a drone can be 1000 times lighter than the tower of a turbine simply because it avoids lever arms.

Unleash the Drones

A simple physical fact cuts costs in half. Can other physical facts double the output? Since wind drones are not restricted by lever arms they can fly higher. They easily reach altitudes twice as high as normal wind towers (300m/1000ft instead of 150m/500ft). Physical fact: on average the wind speed increases with altitude. Physical fact: higher wind speed means more wind power. Physical fact: wind power increases with the cube of the wind speed. Double the wind speed therefore means wind power multiplied by 8 (2³).

Altogether these physical facts lead to the conclusion that there is no such thing as a “bad location” for wind drones. Wind drones only know good and excellent wind sites. They will find enough wind at almost any site.

The impact of height differences can easily be illustrated by using wind data of Dresden (Germany). At the altitude of wind turbines it is a very poor wind location. Not even with the support of the generous German feed-in tariffs does it allow economic energy generation. At wind drone altitude, the wind speed is 60% higher (grey columns). This does not sound spectacular, but due to the cubed relationship between wind speed and power the available wind power almost quadruples (blue columns).

At this altitude Dresden becomes an extremely windy place with a wind force only matched by few wind turbine locations such as coasts, mountains or offshore locations. The world’s largest offshore wind park London Array, has a comparable average wind speed of 9.2 m/s at 100 m hub height. The reason is simple. Obstacles on land like forests, hills and buildings slow the wind down. Offshore winds partly owe their strength to the lack of obstacles. The same applies to high altitude winds: no obstacles to slow them down.

In addition, offshore or high altitude winds are steadier and therefore a more reliable source of electricity. Offshore wind turbines run at full capacity more often. Their idle periods per year are much shorter. Their so-called capacity factor is higher. They are therefore better suited to provide base load electricity. On average the output of offshore turbines is twice as high as that of onshore turbines with the same rated capacity. But since offshore turbines cost two to three times as much as onshore turbines, the advantage is quickly outweighed. Offshore wind energy is still more costly than onshore wind. According to research conducted by E.ON, Germany’s largest utility, offshore wind drones can boost offshore wind turbines’ high yields by another 50%. They can run at full capacity 70% per annum.

In summary, wind drones have lower production costs, they can access much stronger high altitude winds and therefore run at full capacity for greater amounts of time. The estimate of many airborne wind energy startups seems realistic: electricity for a quarter of the price of today’s wind energy.

Google shares this belief in the cost-cutting power of wind drones. Google calculated that less than 16% of all the onshore US sites are suitable for economic wind energy production with wind turbines. For wind drones this figure more than quadruples. 66% of the United States become viable.

The higher capacity factor does not only lower the price, it also increases quality. The intermittency of most renewable energy sources causes a lot of concerns. Electricity grid operators face the challenge of matching the fluctuating production of renewables with demand. Current scenarios foresee the necessity to invest billions into stronger grids and energy storage. If wind drones can produce with a capacity factor of 70% as envisaged by E-ON, they could replace coal, nuclear and gas power plants without the necessity of massive new investments in grid and storage. Grid and distribution costs already make up for the greater part of our electricity bills. The high quality of wind drone power could become a decisive factor, even more important than its low cost.

Time to Market

The first wind drone prototypes are in operation. But when will they be market ready? Soon. Sooner than many other autonomous drones. The reasons: simplicity, safety and the law.

The concepts in real life: Google’s Makani flying wind turbine on the left, and a soft-kite yoyo configuration from German competitor Enerkite. The drum can be seen on the top of the truck. Flying is autonomous, driving is not. © Google Makani, Enerkite

The 600 kW prototype of Google Makani will also fly soon. © Google Makani

Round and Round we Go

Various drones have various tasks which vary in difficulty. Wind drones are the ones with the easy job. They fly the same simple pattern, say a circle, over the same space over and over and over again. Conventional wisdom has it that robots and drones will first get into the dull, dirty and dangerous jobs. Sorry, wind drones, we cannot get you dirty and dangerous, but when it comes to dullness it is hard to beat your job.

Flying the same patterns over the same area means that the sensors know exactly what to expect, that the software has to know only a few flight patterns, and that the only variation can come from different weather, namely changes in wind speed and direction. And if the wind drone has to land for inspection or due to extreme weather, the landing site is also always nearby.

Safety (Makes Them) First

No matter how simple a task, something can always go wrong and in case of flying objects the result can be a crash. To be a commercial success, every drone will have to prove that it is safe.

In the beginning wind drones will only be installed in controlled areas in the countryside, or over the sea, where unauthorized access is not allowed. If the public cannot access the flight area, the public cannot be harmed. This is the simplest recipe for safety. Amazon on the other hand might find it difficult to deliver its parcel to your doorstep while keeping a safe distance from people.

Wind drones also have a built-in safety feature that is unique to drones: They are kept constantly on the leash, pardon, tether. So even if all controls go out of control, wind drones can only crash within the area of the tether and will not do any harm outside.

Stationary operation and the strictly defined flight area of wind drones not only increase safety on the ground but also in the air. Wind drone parks can be included in air maps and turned into no-flight zones for low flying air traffic, just as wind parks are today. Air regulators have already honored the additional safety and special features of wind drones. A draft decree of the European airspace authority EASA has an exemption for wind drones (and other drones on the tether) allowing them to fly higher than other drones without the same restrictions. And under the new EASA “concept of drone operation” the degree of regulation will depend on a specific risk assessment for each use of drones. In case of operation in segregated areas, where drones do not pose a risk to the public, the operator might even approve its own risk assessment. Airspace regulators worldwide are currently working on regulation for drones. They will mostly use comparable flexible concepts, since applying existing strict regulation standards for manned aviation to drones would choke off the respective national drone industry without any safety benefits. So wind drones are not only safer in practice, but this additional safety in the air and on the ground will lead to much lighter regulations. This will make them faster, easier and cheaper to build than other more hazardous and therefore stricter regulated free flying drones or aircraft.

Buy an autonomous car today. It will fit your gear, too.

What is true for drones is also true for autonomous cars. Many believe that autonomous cars will become commercial reality in a few years. This is not true. Fully autonomous cars have long ago hit the market. They have been available for purchase since 2008. Where? At your local Caterpillar or Komatsu dealer, specialized in mining equipment. More and more mines are equipped with fully autonomous haul trucks, which transport rocks and minerals within the mine. Have the engineers at Caterpillar and Komatsu outclassed their counterparts at Google, GM, Tesla, BMW, Volvo, Toyota, Audi, Mercedes by launching their product a decade earlier? Not quite. Haul trucks perform limited and well defined repetitive tasks. They operate stationary in mines, which are controlled distant places with no access for the public. There is little or no regulation on their development and use. The conclusion for drones is obvious.

Huge Market

The strongest argument for wind drones is their potential market: it is huge.

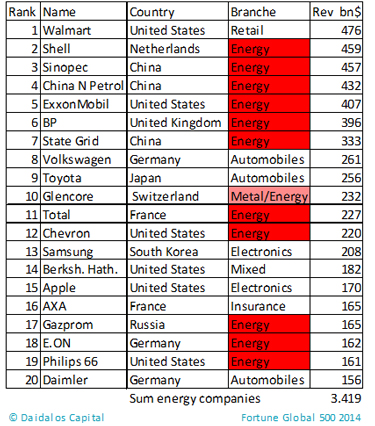

To begin with, the global wind turbine market is a large market. Its volume amounted to USD 80 billion in 2013. Its growth rate averaged 25% per year over the last decade and the market will continue to grow strongly. But wind drones are not limited to the existing market for wind turbines. A look at the top 20 global companies with the largest revenue as compiled by the Fortune Global 500 list illustrates their full market potential:

Energy is big business. But wind energy is still minuscule and accounts for less than 1% of total global energy use. This will change. And it is mostly a question of competitiveness. Onshore wind turbines are on the brink of becoming competitive with coal and natural gas. This so called grid-parity has been reached in some regions. It means that wind energy is already the cheapest source of electricity even without subsidies. Add wind drones’ potential to slash these costs to one quarter, add steadier production and add their ability to be deployed almost anywhere.

This means that wind drones cannot only compete with wind turbines in their niche but will become the cheapest source of electricity. Cheaper than coal, gas, nuclear and hydro power.

And since electric cars are on the rise, the electricity produced by wind drones will be able to play in the energy major league and compete with oil as a transportation fuel. And oil will have a hard time competing, even at the current “cheap” oil prices. Taking into account the inefficiencies of the combustion engine, oil at US$ 60 per barrel is still a more expensive source of power for a car than the electricity produced by today’s wind turbines. Based on the analysis above, oil would have to sell at a quarter of that price, below 15 US$ per barrel to compete with wind drone energy on a pure cost of fuel basis.

The digital revolution has disrupted many markets, created vast riches and young billionaires. But we have to bear in mind that the digital revolution has only taken place in very limited markets so far. The so-called digital giants Google and Facebook – and many others – are all competing for a share of the online advertising market. This market has a total global volume of USD 150 billion. Compare this to the annual average 2 trillion US$ investment into energy supply required in the next 20 years according to the International Energy Agency. Compare this to the 3.4 trillion US$ revenue that the 11 largest energy companies on the Fortune Global 500 list share. Or compare it to the total global energy market that is assumed to have a size of 6 to 10 trillion US$. This is a difference in market size that could come close to a factor of 100. We cannot imagine what it will look like when the drones the digital revolution created take on the largest market of the world, the energy market.

World Changing

We have illustrated how the laws of physics in combination with sensors, chips and smart algorithms can replace the tons of steel and concrete wind turbines are made of. This can make wind drone power cheaper than electricity from fossil fuels. Their ability to harvest stronger winds higher up in the air gives wind drones the potential to provide power where it is needed irrespective of the existing wind resource. Cost-effective electricity made by wind drones could even provide the basis for the clean synthetic fuels of the future. And this fuel could be available at less than today’s oil price.

A lack of wind will no longer be a problem. We have seen how the wind resource dramatically increases by doubling the altitude. But this is only the first humble hop of wind drones into the air. Once these altitudes are mastered, it will be tempting to gradually go higher, until they reach the jet stream at 10 km/33,000 ft. Before, many technical and legal problems will have to be solved. But it will be attempted. The wind resources at this altitude are simply too enticing. The median energy density over New York at this height is more than 10 kW/m² of which about 5 kW/m² can be used. The total energy consumption per person in the US amounts to 10.5 kW. This includes all electricity use, heating, car and aviation fuels, and even industrial energy consumption. This means that harvesting wind in an area of 2 m² (22 sq ft) per person, the size of an open front door, could on average provide all our energy. If 10 wind turbines with today’s dimensions were installed in that altitude over New York, they could have the same rated power as an average nuclear power plant, over 1 GW. High-altitude wind energy is not only an extremely concentrated source of energy, it is also abundant. It can provide about 100 times of today’s global energy consumption. High altitude wind energy could allow us to live a greener lifestyle without the need to reduce our use of energy. For the energy sector this could mean nothing less than finally solving the conflict between economy and ecology.

Burning fossil fuels started the industrial revolution. It enabled the advances of mankind in the last 200 years. Without fossil fuels feeding 7 billion people on this planet would be impossible. But fossil fuels also destroy and pollute nature, poison our cities and homes and cause an ever more dangerous climate change. Furthermore, our reliance on fossil fuels leads to unjustified wealth and power imbalances, to wars over their control and to undemocratic regimes.

When mankind started to burn fossil fuels it made a huge leap forward. When it stops to burn fossil fuels, it will make another big step towards a better world. Drones will help to bring this day much closer than most of us believe today.

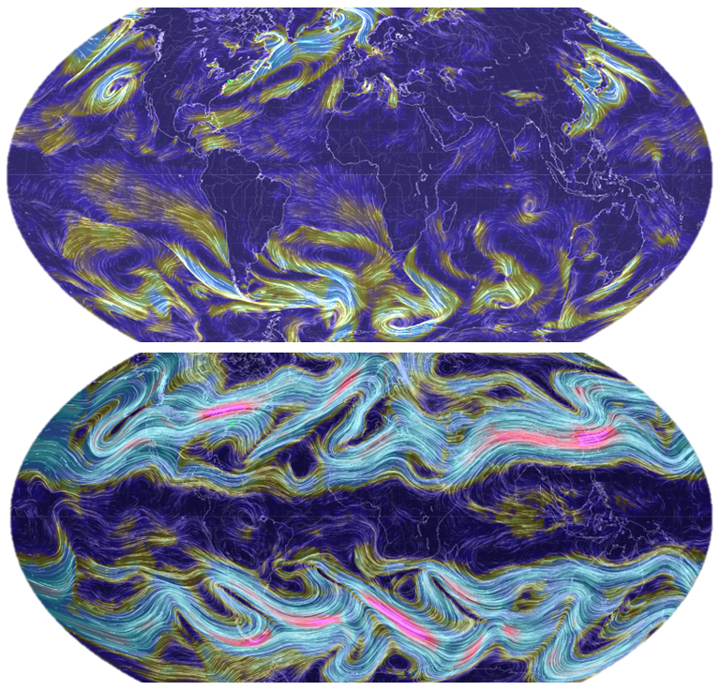

Wind power density at 100m (1) and at 10,500 m altitude (2)

Color code, all figures in kW/sqm:

- dark blue, no stripes: negligible

- dark blue = below 0.5

- brown = 0.5 to 2

- medium blue = 2 to 10

- turquoise = 10 to 40

- red = 40 to 70

- pink = over 70

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product