Industrial Robotics - Articles, Stories & Interviews

Aerospace's Automation Breakthrough: How Robotics and AI Orchestration Are Rewriting the Supply Chain

For aerospace, the next leap will come from integrating physical automation with AI systems capable of coordinating the flow of information across complex, multi-vendor, secure environments that protect confidential information all while transforming efficiency..

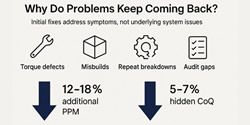

KPI Growth has an enemy called "Recurrence" - Fight it with Standard Work to Sustain the Growth.

Continuous Improvement is often misunderstood as an engine for solving more problems. In reality, the defining capability of a mature operation is ensuring the same problems never return.

Stefa Mini Solutions for Next-Generation Robotic Applications

The Stefa Mini, Cassette and Nano Seals all have smaller cross sections than comparable seals in the market today. This matters because a smaller seal allows for smaller glands (the area the seal slips into on the equipment) and smaller glands mean overall smaller equipment.

Robot-Driven Manufacturing Enables "Lights-Out" Production

The required solution would need to provide seamless connectivity and communication with the RoboDrill machines, as well as additional factory machinery throughout the company targeted for robotic automation moving forward.

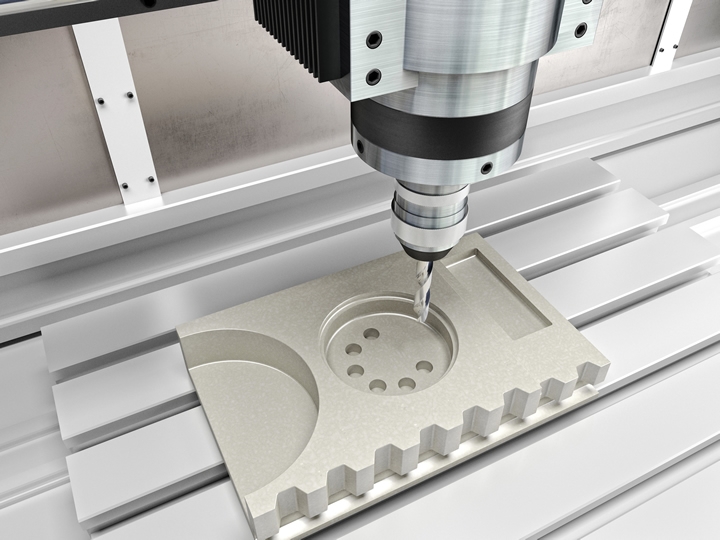

Robotecki Redefines Robotics Precision Cutting and Drilling Applications with RoboDK

With their application, the team at Robotecki not only reduced labor-dependency for these key tasks, they improved the quality of production and throughput.

2025 Top Article - The Future of Machining: Key Trends and Innovations

AI and robotics are seen to deeply disturb specialized industry sectors, bringing beneficial pioneering modernizations in machining, industrial manufacturing and machine shops. Elitsa Krumova explores the future of machining in more depth on behalf of DELMIA.

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

Compared to alternative solutions, such as multiple robots or overhead gantry systems, StackTrax can provide a space and cost-saving alternative that will improve cycle time and overall throughput.

Industrial Robotics - Featured Stories

Powering Robotics: How Networks Enable the Era of "Physical LLMs"

Physical AI describes intelligent systems that can sense, interpret, and act in real environments. Think of self-driving cars navigating busy streets, robotic arms assembling machinery with precision, or smart grids adapting in real time to energy demands.

International robotic safety conference 2025: Key takeaways shaping the future of safe automation

The International Robotic Safety Conference highlighted how rapidly the safety environment is evolving, driven by new standards that reflect innovative robotics technologies and tightening global regulations.

How to Overcome Cobot Design Challenges

Although collaborative robots have become widely available and used in numerous industries, the professionals who design them frequently encounter and must overcome various challenges in cobot design. How should designers address them?

Industrial Robotics - News Headlines

Pickit 3D launches major release of its 3D robot vision solution

Simpler, more powerful and more resilient

New Data Reveals Why Manufacturers Can't Compete for Robotics Talent: A 2x Salary Gap

"The data reveals that manufacturing's hiring challenge isn't about finding qualified engineers. It's about competing with industries paying twice as much," said James Dam, founder of CareersInRobotics.com. The disparity is industry-wide, affecting every sector of the robotics market.

Mouser Drives Electronic Design Excellence with Motor Control Resource Hub for Engineers

Advanced motor control seeks to precisely regulate a motor's speed, torque, and position. These innovations are critical for next-generation mobility and electric vehicle (EV) systems, strengthening both efficiency and driving range.

Industrial Robotics - Featured Product

Robotmaster 2024

Robotmaster 2024

Program multi-robot cells and automatically solve robotic errors with ease. Hypertherm Associates announces a new version to its robotic programming software. Robotmaster 2024 addresses key market trends including the support for programming multiple robots in a single work cell and the demand for automatic trajectory optimization and robotic error correction.

Industrial Robotics - Featured Company

MVTec LLC

MVTec is a leading international manufacturer of software for machine vision used in all demanding areas of imaging like the semi-conductor industry, inspection, optical quality control, metrology, medicine or surveillance. In particular, software by MVTec enables new automation solutions in settings of the Industrial Internet of Things. MVTec is the developer and vendor of the general purpose machine vision software products HALCON and MERLIC.