VIVALDI Digital Solutions GmbH has developed an exemplary, innovative solution for AI quality inspection in real time. In addition to an edge server with an Intel processor, intelligent image processing plays a key role in the so-called SensorBox.

Multi-camera system with AI and seamless traceability leaves no chance for product defects

Multi-camera system with AI and seamless traceability leaves no chance for product defects

Case Study from | IDS Imaging Development Systems

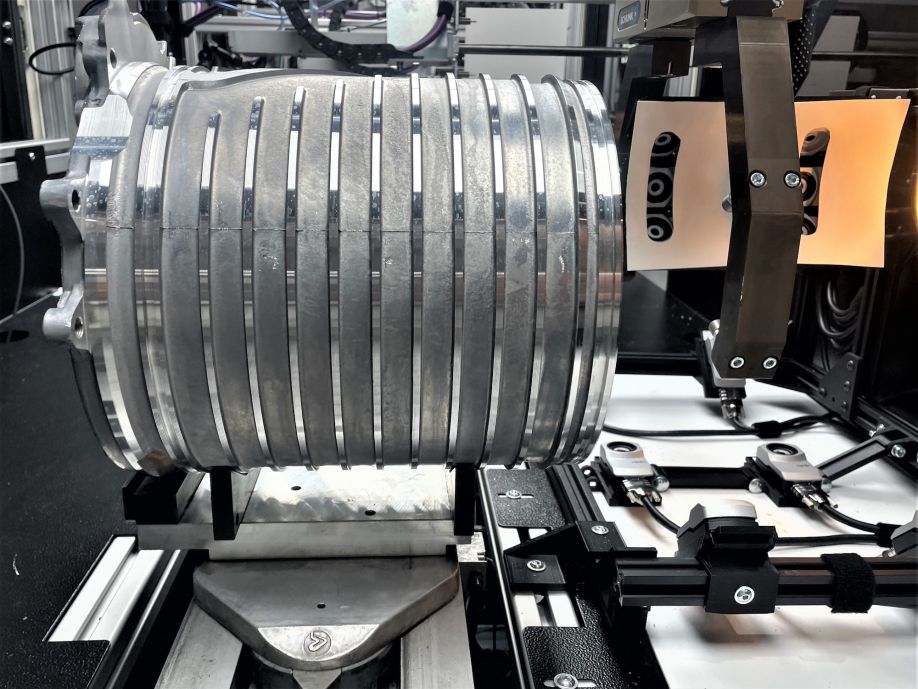

In areas such as high-precision metalworking, accuracy is non-negotiable. This includes the automotive industry and its suppliers, which is in crisis in Germany for a variety of reasons. The industry is under enormous pressure to deliver products of impeccable quality and at the same time reduce operating costs, for example by increasing process speeds. The automotive industry's quality assurance standards are strict, the component geometries are complex and the demands on precision and process reliability are enormous. Fluctuations in detection, insufficient traceability to individual serial numbers or batches and changing environmental conditions can lead to costly errors, production downtime and complaints.

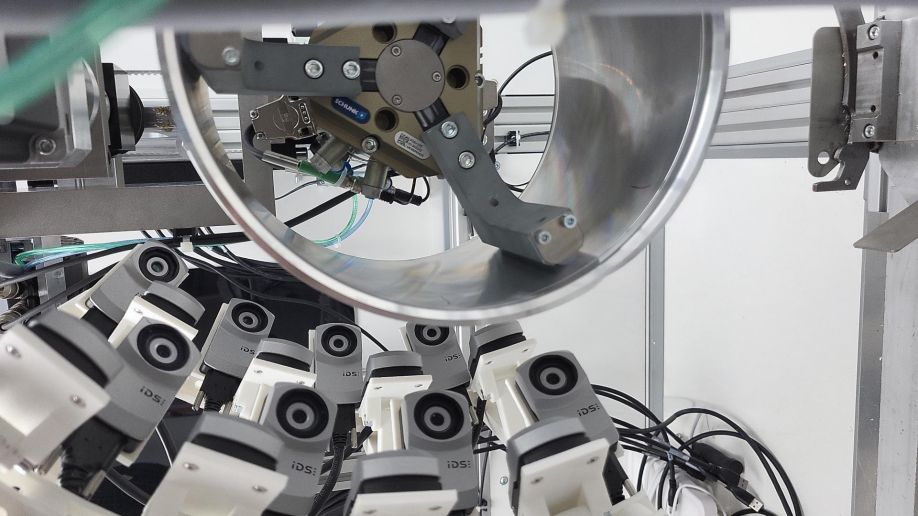

VIVALDI Digital Solutions GmbH has developed an exemplary, innovative solution for AI quality inspection in real time. In addition to an edge server with an Intel processor, intelligent image processing plays a key role in the so-called SensorBox. Designed for an automotive supplier and its production site in the Czech Republic, up to 70 USB3 uEye+ XC autofocus cameras from IDS Imaging Development Systems perform automatic visual inspection for surface inspection in several inspection cells.

Round component geometries with strong reflections must also be inspected with process reliability

Simultaneous image recording ensures a complete inspection and helps to maintain the cycle time

Why did the AI specialist choose the uEye XC camera from IDS?

"The BSI pixel technology enables the sensor to deliver consistently precise and reliable results, even in changing light conditions," explains Jürgen Hejna, Product Owner 2D cameras at IDS. It is not only the excellent low-light performance and minimal pixel noise that make the sensor particularly suitable for this application. "The 24x digital zoom, combined with auto white balance and precise color correction, contributes significantly to the success of this demanding test procedure," emphasizes Jürgen Hejna.

AI-supported analyses and synchronous camera control via edge server

Image processing is carried out via an optimized infrastructure. Up to eight cameras can be connected per USB hub, enabling simultaneous recording of several inspection areas. A maximum of two of these USB hubs are connected to a self-developed 'cam controller', which bundles and processes the image signals. Several cam controllers are networked with the edge server. This server not only calculates the AI-supported analyses, but also communicates directly with the system controller, which coordinates the triggering of the cameras and ensures synchronized recording.

"Image processing is a central component for traceability, which is the actual technological centerpiece of the solution, and IDS is the ideal partner for this point”, underlines Uwe Siegwart. "Digitized quality data acquisition in real time and linking with other production parameters not only increases efficiency, but also significantly reduces rejects and rework. Errors are minimized, costs are reduced and production processes are optimized."

The system has already paid off in the Czech Republic: The number of complaints per year has been reduced by two thirds and the number of unrecognized surface defects has even been reduced to zero.

Outlook

Camera

uEye XC - Automatically perfect images

Client

About IDS Imaging Development Systems GmbH

IDS Imaging Development Systems GmbH is a leading manufacturer of industrial cameras and pioneer in industrial image processing. The owner-managed company develops modular concepts of powerful and versatile USB, GigE and 3D camera as well as models with Artificial Intelligence (AI). The almost unlimited range of applications covers multiple non-industrial and industrial sectors of equipment, plant and mechanical engineering. The AI image processing platform IDS NXT is extremely versatile and opens up new areas of application where classic rule-based image processing reaches its limits. With visionpier, IDS operates an online marketplace that brings together suppliers of ready-made image processing solutions and interested end customers in a targeted manner.

Since its foundation in 1997 as a two-man company, IDS has developed into an independent, ISO and environmentally certified family business with around 350 employees. The headquarters in Obersulm, Germany, is both a development and production site. With branches and representative offices in the USA, Japan, South Korea, the UK, France and the Netherlands, the technology company is also globally represented.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

IDS Imaging Development Systems Inc.

World-class image processing and industrial cameras "Made in Germany". Machine vision systems from IDS are powerful and easy to use. IDS is a leading provider of area scan cameras with USB and GigE interfaces, 3D industrial cameras and industrial cameras with artificial intelligence. Industrial monitoring cameras with streaming and event recording complete the portfolio. One of IDS's key strengths is customized solutions. An experienced project team of hardware and software developers makes almost anything technically possible to meet individual specifications - from custom design and PCB electronics to specific connector configurations. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency and flexibility for your application.

Other Articles

High-precision process monitoring and error detection in additive manufacturing

Inspection of critical infrastructure using intelligent drones

Automate 2025 Q&A with IDS Imaging

More about IDS Imaging Development Systems Inc.

Featured Product