It's true that advanced simulation tools have helped improve the efficiency and effectiveness of robotic workcell design and path planning, but it still remains an incredibly time consuming process.

Key Considerations for Maximizing Manufacturing Efficiency

Key Considerations for Maximizing Manufacturing Efficiency

Ville Lehtonen, Vice President of Product, | Realtime Robotics

Robotic automation has become a cornerstone of productivity, revolutionizing industries such as manufacturing, warehousing, and logistics. However, achieving peak performance in multi-robot workcells remains a significant challenge. Often measured by cycle time, optimizing the performance of each workcell is critical to ensuring production lines operate at maximum efficiency - avoiding bottlenecks, and maintaining throughput.

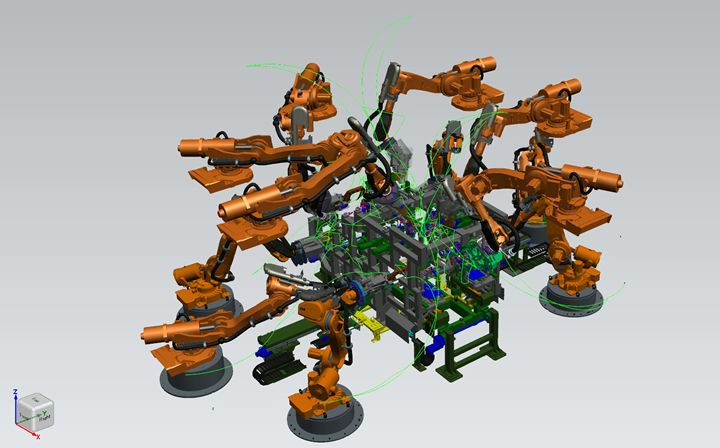

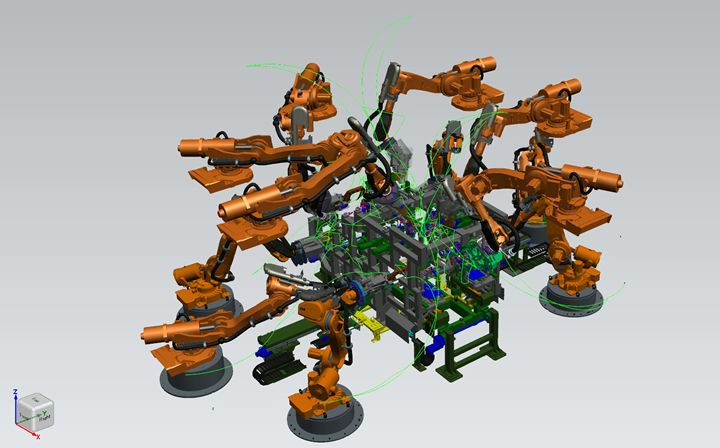

While adding more robots to a workcell might seem like a straightforward way to enhance productivity, this approach can introduce new complexities rather than solve existing issues. It’s true that advanced simulation tools have helped improve the efficiency and effectiveness of robotic workcell design and path planning, but it still remains an incredibly time consuming process. In fact, any automation offered within current simulation tools only considers how to improve the operations of one robot at a time.

The Challenge of Optimization

The design and path planning of robotic workcells is a complex process that involves assigning tasks, sequencing actions, and choreographing movements to prevent collisions - all while striving to achieve the fastest possible cycle time. For even a small number of robots and tasks, the number of potential configurations is enormous - making it nearly impossible for engineers to manually explore all options.

Typically, the only way to accomplish the goal of faster, more efficient workcell path planning is to leverage engineers with years of experience, who know some of the best tricks for wringing out additional seconds from a design. However, the industry needs to come to grips with the fact that the number of truly experienced simulation engineers in the workforce is dwindling - and those that remain don't have the capacity to both design workcells and coach the few new engineers entering the workforce. Not to mention that, despite their expertise, there are still limits on just how fast a human can design and test different configurations.

A primary bottleneck in this process is motion planning; i.e., determining how robots will move in sync to complete tasks without collisions. Motion planning for robots with multiple degrees of freedom is time-intensive - and the entire path planning process often has to be restarted if task assignments or sequences are adjusted. For years, the manufacturing and logistics industries have only had one answer to this problem - to throw more and more engineers at it until a solution is found.

From Bottlenecks to Breakthroughs

One of the biggest barriers to smarter automation in today’s factories is the limited amount of “horsepower” available to solve complex robotic workcells. A lot of the damage here is subtle, as the tricks commonly used to reduce complexity have other costs, typically in the form of more hardware and more floor space use. Instead of having two robots palletizing side by side, organizations can avoid the collision problem by installing a dual lane converter in the conveyor, and placing two palletizer stations instead of one. The floor space and conveyor costs are considerable, but nobody blinks an eye because solving for the robot proximity is considered far too risky.

Similarly to this, the status quo has ripple effects across the entire production lifecycle. It discourages teams from making incremental improvements to processes that could deliver significant gains. It also delays critical paths in bringing new products to market - especially in industries where speed is everything. Worse still, it makes any late-stage design changes - such as modifications to a car model already in development - painfully costly and disruptive. Reinvesting in modern, AI-powered automation tools can change that trajectory, giving factories the agility, insight, and efficiency needed to stay competitive.

The path forward lies in adopting technologies that go beyond brute-force programming and instead enable intelligent automation from the start. Advanced tools - especially those utilizing AI while remaining deterministic - can automatically generate optimized robot paths, prevent collisions before they happen, and streamline the entire design-to-deployment process. This not only frees engineers to focus on higher-value work, it also opens up far cheaper and lower floor space options and makes it far easier to adapt to changes midstream, without blowing up timelines or budgets. By reinvesting in smarter solutions, manufacturers can unlock faster cycle times, reduce rework, and make better decisions earlier in the process - all of which lead to more agile, profitable operations.

Designing for High-Performance

To unlock the full potential of robotic automation, manufacturers and engineers must take a new overall approach. The key is to enable engineers to work to their fullest potential, focusing on the whole workcell - not just a single robot at a time. Future success hinges on the ability to provide engineers with the tools and new approaches needed to solve complex problems more efficiently.

Here are some best practices that organizations should consider:

- Understand the Task

Is the task at hand static or dynamic? Are there existing products on the market that solve this problem? How much is this problem worth it to your organization to solve? As the expertise of an outside company will likely be necessary, the conversation can be simplified a lot by having a clear number in mind at the start of the conversation. You might be positively surprised.

- Can You Adapt to Changes?

It is reasonable to assume that during a 50,000h MTBF robot lifetime, things will change. A conservative assumption would consider some changes every 2 years. Price those in as you plan, and make sure any ROI doesn’t get demolished.

- Don’t Reinvent Wheels, Or Pay Someone Else To Do So

The leading edge of robotics technology is constantly in motion, and an organization might end up spending tens, if not hundreds of thousands of dollars, solving a problem that has already been solved. This can be challenging, but a good test of a potential partner is asking them about what “the state of the art” is for solving the problem at hand. Robot positioning, motion planning, collision avoidance and more are frequently used as reasons for massive invoices, but much of that is unnecessary labor by now.

- Collaboration and Scalability

Ensure that workcell programming solutions integrate seamlessly with existing hardware and software platforms. Scalable tools allow manufacturers to adapt to changing demands and expand their operations without sacrificing performance.

- Sustainability

Emerging technologies are paving the way for solutions that not only improve cycle times, but also address energy consumption, floor space usage, and overall system sustainability. By incorporating these variables into the overall optimization process, manufacturers can reduce waste, lower operating costs, and contribute to a greener industrial ecosystem. In addition, upcoming regulations will require various sustainability measures - such as CO2 emissions occurring during production - to be tracked and reported. Solutions that can help improve energy efficiency will stand out.

The Future of Manufacturing Optimization

To compete in today’s global manufacturing environment, it’s no longer enough to simply automate; you have to automate intelligently. For organizations that do not own hundreds of robots, integration tends to cost 5x more than the robots. This creates a situation where minor robotic installations can take well north of half a decade to pay themselves back, and in practice it might require dozens of robots to get a truly great ROI. In a world where 93% of American factories employ less than 100 people, this paradigm keeps the advantage with big companies.

Organizations need to keep an eye out for technological advances, and integrators that take advantage of them rapidly, to make sure investments will not only be an educational adventure, but an actually profitable project. One that has a great ROI - and can make the organization competitive in spaces and geographies where it was previously priced out.

The future of factory automation depends on breaking free from outdated constraints and giving engineers the power to design, iterate, and optimize with confidence, instead of being beaten down with mundane, repeatable tasks. The tools exist. The opportunity is now.

Ville Lehtonen is the VP Product at Realtime Robotics. He has worked in robotics for over 17 years, with experience spanning Life Sciences, Logistics, and Manufacturing. In Life Sciences, Ville contributed to automation innovation at both LabMinds and HighRes Biosolutions. In Logistics, he led product at Pickle Robot, helping scale AI-powered unloading systems into commercial operation. Most recently, he has focused on real-time motion planning and adaptive control for high-mix manufacturing environments. Ville holds graduate degrees from Oxford University and Aalto University, with a background in both business and computer science. Originally from Finland, he currently resides in Boston, MA.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product