By giving robots and humans the same voice, real-time escalation systems transform factories into agile, responsive, and collaborative environments. They ensure that no signal-machine or human-goes unheard.

Giving Robots and Humans the Same Voice: Real-Time Escalation Systems for Smart Factories

Article from | Orca Lean

Walk into any modern factory today and you’ll see a carefully orchestrated dance between humans and machines. Robots handle repetitive precision work, operators oversee lines, supervisors track production, and managers keep an eye on output. But despite all this technology, a single unresolved issue—a stalled robot, a jammed conveyor, a missing part—can bring the entire system to a grinding halt.

The irony? Robots already know when something is wrong. They flash alarms, send digital error codes, or stop entirely. Humans, too, often see problems early—a strange vibration, a material misfeed, or a small defect creeping into the output. Yet both sides often struggle to get the right people’s attention at the right time.

Why? Because while robots and humans generate signals, factories still rely on outdated escalation methods: whiteboards, radios, emails, or manual reporting. In an era where every second of downtime can cost thousands of dollars, this gap is unsustainable.

The solution lies in real-time escalation systems—platforms that give both robots and humans a unified voice so issues can be acted on instantly.

The Escalation Problem in Modern Factories

Smart factories are increasingly powered by robotics. Assembly cobots, automated guided vehicles, and machine vision systems generate a flood of data every second. This makes operations faster and more reliable—but also more complex.

Here’s the challenge:

- A robot arm halts mid-cycle and sends an error signal. But the alert remains local, visible only to the nearest operator.

- That operator, juggling multiple responsibilities, can’t immediately notify maintenance.

- By the time the supervisor hears about it, 20 minutes of lost production have already piled up.

Multiply this scenario across multiple lines, shifts, and plants, and the financial impact is staggering. Studies show that unplanned downtime can cost manufacturers $20,000 to $30,000 per minute in lost productivity and wasted materials.

Traditional escalation tools—whiteboards, emails, phone calls—can’t keep pace with this environment. They are slow, fragmented, and lack visibility across teams. In robotics-driven plants, the communication gap between machine signals and human escalation becomes a bottleneck that directly hits throughput and profitability.

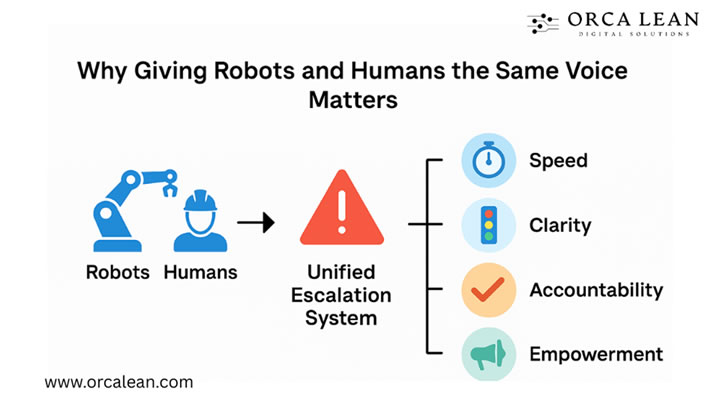

Why Giving Robots and Humans the Same Voice Matters

Think of robots as specialists who speak in error codes and binary signals. They can say, “Something is wrong,” but they can’t explain why. Humans, on the other hand, bring context: “The sensor fault is recurring because the wiring harness is loose,” or “This misalignment started after yesterday’s changeover.”

When these two voices are separated, delays creep in. The robot’s alarm blinks, but no one knows until an operator flags it. The operator sees the problem, but can’t find the supervisor. The supervisor gets the message late, and by then, the issue has escalated into lost output and frustrated workers.

A unified escalation system solves this by ensuring:

- Speed: Both robot alarms and human inputs appear instantly on shared dashboards.

- Clarity: Everyone sees the same red/yellow/green signals, reducing confusion.

- Accountability: Escalations are tracked, not lost in hallway conversations.

- Empowerment: Operators no longer feel like they’re “shouting into the void.”

For manufacturers, the payoff is measurable. Faster mean time to resolution (MTTR), fewer prolonged stoppages, and a culture where problems are surfaced and solved rather than hidden. In the context of Industry 4.0, this is the missing piece—not just machines talking to machines, but machines and humans talking together.

Features of Real-Time Escalation Systems

So what does a true real-time escalation system look like in practice? The best platforms combine robotic signals, operator feedback, and visual management into a single environment. Key features include:

- Centralized Alerts: Whether it’s a robotic stoppage, a safety incident, or a material shortage, all issues funnel into one system—no more scattered messages.

- Visual Displays: Factory-wide screens make issues impossible to ignore. A red signal on Line 2 is instantly visible to operators, supervisors, and managers alike.

- Escalation Rules: Automatic routing ensures the right person is notified. A quality issue goes to the quality manager; a machine fault pings maintenance.

- Traffic-Light Indicators: Standardized urgency markers (green/yellow/red) allow teams to prioritize quickly without endless debate.

- Mobile and Tablet Access: Operators can escalate issues with a single tap, even while on the line—eliminating lag.

- Audit Trail: Every escalation is logged, creating a valuable data set for root cause analysis and continuous improvement.

Together, these features shift escalation from a chaotic process into a structured, proactive system.

Comm Screen in Action: Unifying Factory Communication

This is where OrcaLean’s Comm Screen steps in. Designed for the realities of the shop floor, Comm Screen brings robots and humans onto the same stage.

Imagine a real scenario:

- A robot on Line 3 halts due to a sensor fault. Instead of flashing an isolated light, the signal instantly appears on a factory-wide Comm Screen display.

- The nearest operator adds context: “Recurring fault after last night’s changeover.”

- A supervisor sees the escalation in real time, assigns maintenance, and updates status within minutes.

Instead of waiting for word-of-mouth escalation, the issue is captured, displayed, and resolved in record time.

For VPs and plant managers, this translates into:

- Clarity: They see the same information operators see, without relying on filtered reports.

- Speed: Problems are resolved before they snowball into hours of lost output.

- Culture: Operators feel empowered, knowing their voice is amplified alongside machine signals.

By merging robotic data with human input, Comm Screen doesn’t just reduce downtime—it creates a more connected, collaborative factory culture.

The Bigger Picture: Escalation as a Competitive Advantage

Factories often chase metrics like OEE, scrap rate, and FTQ. But behind every one of these numbers lies a common driver: how fast and effectively problems are escalated and solved.

Companies that master escalation:

- Recover faster from stoppages, minimizing lost throughput.

- Build stronger cross-shift alignment, since every escalation is visible and logged.

- Drive continuous improvement, as logged escalations highlight recurring issues worth solving permanently.

As factories move toward Industry 5.0—where robotics and humans collaborate more closely than ever—escalation systems will evolve further. Integration with AI, predictive analytics, and ERP/MES systems will allow not just faster responses, but proactive interventions.

In other words: escalation is no longer just a fire drill. It’s a strategic capability.

Conclusion

Smart factories thrive on seamless communication. But when robots and humans speak in different languages, silence is expensive. Every minute of downtime, every missed signal, every unresolved issue eats into margins and morale.

By giving robots and humans the same voice, real-time escalation systems transform factories into agile, responsive, and collaborative environments. They ensure that no signal—machine or human—goes unheard.

OrcaLean’s Comm Screen is built for exactly this purpose: to unify alerts, instructions, and escalations so factories can cut downtime, empower teams, and keep production moving.

Because in today’s manufacturing world, silence costs too much.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product