DESTACO Unveils the eRDH Series Electric Parallel Gripper: The Future of Automated Handling

This latest addition to the DESTACO Robohand product line represents a significant leap forward in gripping technology, offering unparalleled precision, flexibility, and ease of use.

How Autonomous AI Tackles Quality Control Costs

Quality is often viewed as a direct driver of customer satisfaction and operational efficiency in manufacturing. Yet some organizations fail to recognize the hidden costs of quality issues, significantly impacting the bottom line.

Battery inspection using machine vision - fast, reliable, and variable

Averna has developed a procedure for automating battery inspection for one of its customers. The fact that potential errors are extremely varied increases the complexity of the inspection process.

How to Achieve the Full Benefits of a Warehouse Digital Twin

A warehouse digital twin needs more than a highly capable WMS, it also needs a reliable technology to capture all the necessary inventory data, and this is where computer vision plays a pivotal role.

Physical AI: Embracing AI's Moment in Robotics

Manufacturers currently use automation to streamline workflows, enhance efficiency, cut costs, and meet growing consumer demands. Yet they face a myriad of disruptions such as labor shortages, limitations of current technologies, and costly downtimes on production lines.

From Displacement to Empowerment: How Robotics Developers Can Lead the Workforce Reskilling Revolution

As automation continues to integrate into our factories, warehouses, and supply chains, the conversation around workforce transition and reskilling has become one of the most urgent and defining challenges of our time.

Multi-axis motion control drives pipe-based robots

Surveying and maintaining underground pipes can be complex and resource intensive. To streamline the process, construction and facility management teams are increasingly turning to robots that can provide inspection as well as repair.

How AI, Robotics, and Automation Power Next Generation Pack Assembly

Successful pack assembly systems balance throughput, quality, and safety in real time. Integration matters more than buying the most sophisticated robots; it comes down to seamless software logic, modular failover paths, and smart system design.

How Is Modular Robot Design Reshaping Factory Automation?

How industrial robots work constantly adapts to increased demand and novel technologies, but it enhances automation potential the most. What is shifting and how can production engineers and electronics experts in these sectors fully leverage the benefits?

Multi-camera system with AI and seamless traceability leaves no chance for product defects

VIVALDI Digital Solutions GmbH has developed an exemplary, innovative solution for AI quality inspection in real time. In addition to an edge server with an Intel processor, intelligent image processing plays a key role in the so-called SensorBox.

What is the role of cameras in pick and place robots?

Pick and place robots perform repetitive handling tasks with speed and consistency, making them invaluable across industries. These robots depend heavily on the right camera setup. Get insights about the challenges faced by cameras, use cases, and their biggest benefits.

System lets robots identify an object's properties through handling

With a novel simulation method, robots can guess the weight, softness, and other physical properties of an object just by picking it up.

Automate 2025 Product Preview

Automate 2025 takes place May 12th - 15th in Detroit, MI. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Addressing Challenges in Software Solutions for Robots and Physical AI

We leveraged our long heritage and leadership in robotics to create an AI software product that helps our customers overcome the challenges of traditional automation, accelerate set-up and deployment, and achieve greater ROI from their existing automation systems.

Automate 2025 Q&A with DESTACO

There's nothing like seeing our products in action. We will have live demonstrations, giving attendees the chance to see the performance and capabilities of our solutions up close and personal.

Records 1 to 15 of 2113

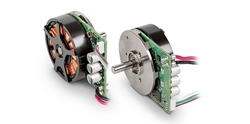

Industrial Robotics - Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.

.jpg)