CMU's interactive tool helps novices and experts make custom robots

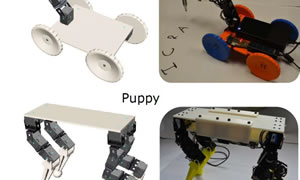

Phys.org: A new interactive design tool developed by Carnegie Mellon University's Robotics Institute enables both novices and experts to build customized legged or wheeled robots using 3D-printed components and off-the-shelf actuators.

Phys.org: A new interactive design tool developed by Carnegie Mellon University's Robotics Institute enables both novices and experts to build customized legged or wheeled robots using 3D-printed components and off-the-shelf actuators.

sing a familiar drag-and-drop interface, individuals can choose from a library of components and place them into the design. The tool suggests components that are compatible with each other, offers potential placements of actuators and can automatically generate structural components to connect those actuators.

Once the design is complete, the tool provides a physical simulation environment to test the robot before fabricating it, enabling users to iteratively adjust the design to achieve a desired look or motion.

"The process of creating new robotic systems today is notoriously challenging, time-consuming and resource-intensive," said Stelian Coros, assistant professor of robotics. "In the not-so-distant future, however, robots will be part of the fabric of daily life and more people—not just roboticists—will want to customize robots. This type of interactive design tool would make this possible for just about anybody." Full Article:

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product