Tote-To-Person AMR – a market and technology study from Interact Analysis & Geek+

Mobile warehouse automation is dominated by goods-to-person (G2P) solutions. These see autonomous mobile robots (AMRs) carry entire racks of goods to human pickers. Now, G2P is evolving. The latest tote-to-person AMR (T2P AMR) solutions enable robots to bring individual totes to pickers, instead of whole racks. There will still be plenty of room for traditional G2P solutions to continue but, in many scenarios, the benefits of T2P AMR are impressive and include significantly increased warehouse storage capacity as well as very high picking efficiency.

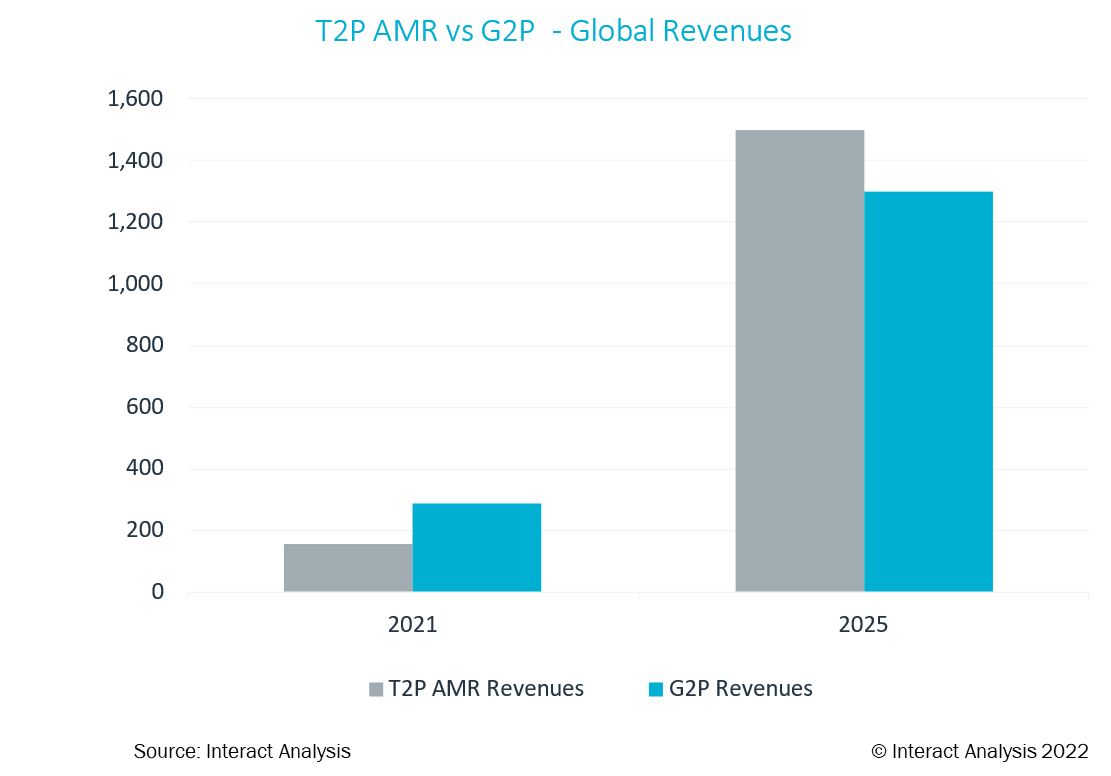

Market data from Interact Analysis shows that there is a strong future for T2P AMR solutions. In 2021, revenues from T2P AMR were $154 million, compared to $289 million for standard G2P. By 2025, revenues from T2P AMR will for the first time outpace sales of standard G2P solutions, at $1.5 billion, compared to $1.3 billion for standard G2P.

Aside from the efficiency benefits it brings to customers, two wider trends are also driving T2P AMR adoption. One of these is e-commerce growth. For example, in 2011, US e-commerce sales were 4.5% of total retail sales. By 2019 they had grown to 10%. When the pandemic hit, things accelerated radically, and 12 months later e-commerce had hit 15% of total retail sales. While growth will slow down to some degree as the pandemic eases back, there is no doubt we can expect permanently accelerated rates of e-commerce growth for the foreseeable future. For warehouse managers, this implies that it will be a busy time: currently, it is estimated that for every $1 billion in additional online sales, an additional 1 million square feet of warehousing is needed to support it.

The other big trend is the labor shortage which, like e-commerce growth, shows no sign of disappearing alongside the pandemic that caused it. For example, in February, CNN reported that there were 11.3 million US job openings. This amounted to 1.8 jobs for every job-seeking American. Both these trends are radically increasing demand for T2P AMR which can alleviate the need to build new warehousing by significantly increasing the storage capacity of existing warehouses and can also alleviate the impacts of the labor shortage by improving picking efficiency.

Understanding the T2P AMR market

In the rest of this article, we’ll explain how T2P AMR works with reference to two key T2P AMR offerings that are available from Geek+: PopPick and the RoboShuttle solution.

RoboShuttle

The RoboShuttle solution is in fact a combination solution – it uses RoboShuttle tote transfer robots to remove individual totes from storage racks, and then passes the totes to P40 picking robots. The difference is that instead of carrying a whole rack, the P40 only carries a single tote over to the picker.

Why is this a benefit? Firstly, it can increase warehouse storage capacity by up to three times. This is achieved because, with RoboShuttle, the storage shelves can be up to eight meters high, much higher than would be possible for traditional G2P solutions where the entire rack must be moved regularly. In many warehouses today using G2P, the higher area in the warehouse is simply wasted. With T2P AMR, in most cases, the warehouse ceiling is the only real limitation for storage. Meanwhile, the efficiency of the picking robots enables the ability to pick up to 400 totes per picking station per hour, and a flexible design means that customers have the freedom to reuse existing shelves, racks, and lofts if desired.

PopPick

Another variant on T2P AMR from Geek+ is PopPick. This solution works slightly differently. Entire racks are still moved by P-series picking robots. However, with a PopPick solution, workers have a special picking station with two built-in automated pickers that select individual totes and present them to human pickers. This enables high-density storage with 12 columns of totes stored in rows that have only 20mm gaps between totes – an increase in storage density of up to four times. The solution can also result in picking efficiencies of up to 650 totes per picking station per hour and is 50% cheaper on average than traditional solutions.

To learn more about the future of the T2P AMR market, and the new technologies that are driving that market, download this new whitepaper, produced by a collaboration of market intelligence company Interact Analysis and Geek+.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product