ABB and Cosmic use AI-powered robots to rebuild homes in Los Angeles area

ABB Robotics is enabling faster, safer and more cost-effective rebuilding in areas devastated by the 2025 Southern Californian wildfires through a collaboration with Cosmic Buildings – a leading construction technology company that uses proprietary mobile robotic microfactories. After the wildfires burned thousands of acres, destroying homes, infrastructure, and natural habitats, this pioneering initiative will deploy the microfactory in Pacific Palisades, California, to build modular structures onsite, offering a glimpse into the future of affordable housing construction.

“Together, Cosmic and ABB Robotics are rewriting the rules of construction and disaster recovery,” said Marc Segura, President of ABB Robotics Division. “By integrating our robots and digital twin technologies into Cosmic’s AI-powered mobile microfactory, we’re enabling real-time, precision automation ideal for remote and disaster-affected sites. In the face of labor shortages and rising costs, this shows how automation can transform housing construction, by building faster, safer and smarter.”

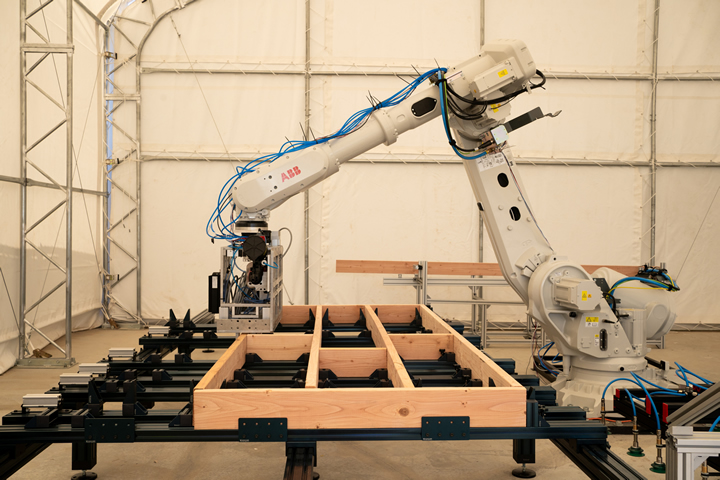

At the heart of the innovation is the integration of ABB’s IRB 6710 robots and RobotStudio® digital twin software with Cosmic’s Robotic Workstation Cell and AI-driven Building Information Model (BIM) – an end-to-end platform that handles design, permitting, procurement, robotic fabrication and assembly. Housed within an on-site microfactory, these systems fabricate custom structural wall panels with millimeter precision and deliver them just in time for assembly at the construction site. Launched in response to the devastating Palisades and Eaton fires, which destroyed more than 16,000 structures, Cosmic’s mobile factory marks a turning point for resilient, fast, and affordable housing solutions, aiming to build 100 homes by 2027.

Cosmic integrates ABB’s RobotStudio into their AI BIM allowing the entire build process to be simulated and optimized in a digital environment before deployment. Once on location, Cosmic’s AI and computer vision systems work hand-in-hand with the robots, making real-time decisions, detecting issues, and ensuring consistent quality. Cosmic’s homes are built with non-combustible materials, solar and battery backup systems, and water independence through greywater recycling and renewable water generation. Each home exceeds California’s wildfire and energy efficiency codes. By delivering a turnkey experience from permitting to final construction, Cosmic is redefining what’s possible in emergency recovery.

The global construction robotics market is expected to grow by 20 percent CAGR until 2030*. Cosmic’s mobile microfactory reduces construction time by up to 70% and lowers total building costs by approximately 30% compared to conventional methods. Homes can be delivered in just 12 weeks at $550–$700 per square foot, compared to Los Angeles’ typical $800–$1,000+ range. The process also minimizes waste and improves build quality, easing the burden on homeowners facing underinsurance and inflated rebuilding costs.

“We’re not just building homes; we’re rebuilding the playbook,” said Sasha Jokic, Founder and CEO of Cosmic Buildings. “Our mobile microfactory is fast enough for disaster recovery, efficient enough to drastically lower costs, and smart enough not to compromise on quality. By integrating robotic automation with AI reasoning and on-site deployment, Cosmic achieves construction speeds three times faster than traditional methods, completing projects in as little as three months.”

The initiative in Los Angeles is part of a global movement to transform construction through automation, driven by ABB Robotics. By equipping partners with advanced tools and expertise, ABB is addressing the most pressing challenges in the construction industry, such as labor and skills shortages, excessive waste, sustainable resource use, and the growing need for affordable housing.

Through real-world applications such as Cosmic Buildings, ABB is redefining how buildings are designed and delivered – making construction more resilient, resource-conscious, and accessible where it’s needed most. For more information on robotics in construction please visit new.abb.com/products/robotics/industries/construction.

*Internal analysis based on ResearchGate, McKinsey and Global Market Insights

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 105,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

Cosmic Buildings is a Public Benefit Corporation and construction technology company redefining how homes are designed and built. By combining a proprietary AI-driven, end-to-end software platform with mobile robotic microfactories, Cosmic delivers custom, fire-resistant, net-zero homes that are built 3x faster and at 30% lower cost than traditional methods. Cosmic’s first microfactory is now operating in Los Angeles, supporting more than 35 families in rebuilding homes lost to wildfire. As part of its 1:10 Initiative, Cosmic donates one home for every ten sold to families recovering from disaster. With mobile, autonomous, and cost-efficient factories, Cosmic is expanding nationwide to bring resilient, sustainable housing to communities across the country.

Featured Product