How Many Axes Does Your Robotic Positioner Need?

If you're considering a robotic positioner, you have probably already looked at several different models. You've probably seen single-axis turntables, double-axis positioners, and multi-axis ferris wheels. You've probably explored different brands, styles, and price ranges.

MARS - Mobile Arm Robot System

In response to the growing demand for improved robotic assistance in industry sectors such as retail and light industry, we created MARS, the Mobile Arm Robot System, a robot with more sophisticated autonomous navigation and inspection capabilities.

World's first haptic telerobot hand (Tactile Telerobot) to officially launch at first public event at CEATEC 2019 in Japan

The exhibit will be divided into several scenario-based themes, each demonstrating a distinctive way to implement the technology. There will be scenarios for the use of robots in a kitchen, school, fish market, living room, laboratory and skill sharing.

Using FPGA Supercomputers to Build a High Precision Robot

We solve the motion platform problem with a combination of innovative techniques. These include: an extremely accurate sensor system, high speed computing, optimized power to weight ratio, and 3D printed parts.

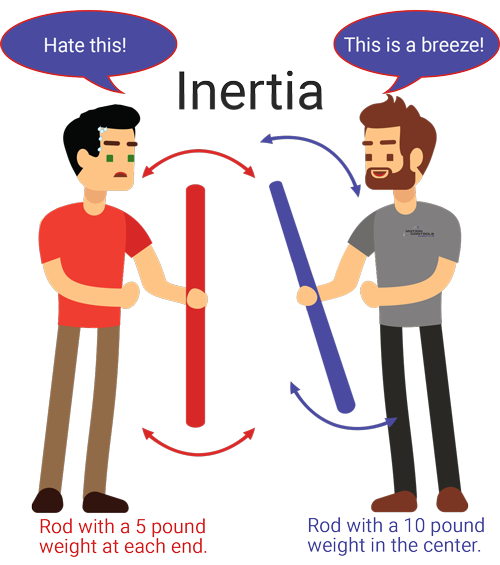

Robot Inertia vs Payload

Payload and inertia are both important factors when designing End of Arm Tooling and selecting a robot. The differences between the two and how they affect choosing a robot is explained in this article.

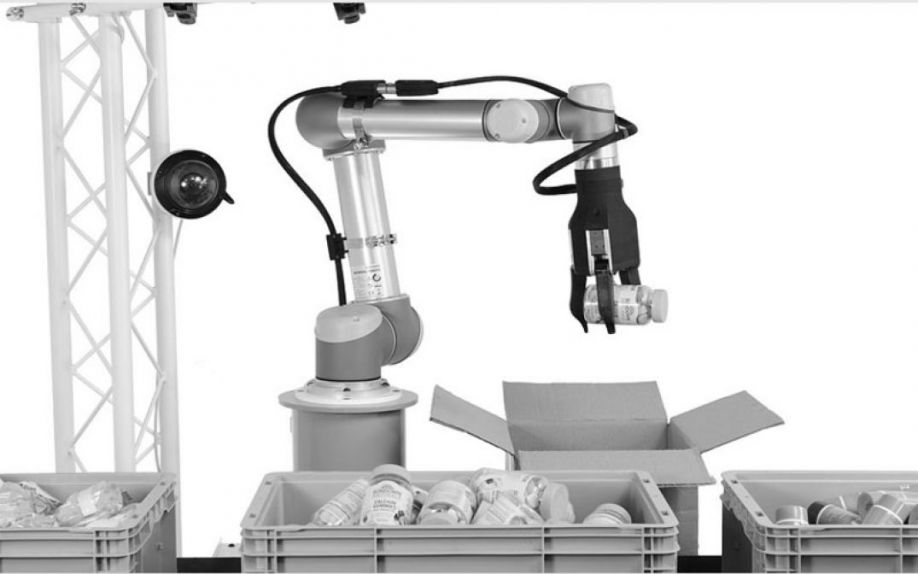

Smart grasping demonstrated at Automate and ProMat trade shows

Tactile sensing and force feedback are - and have been - problem areas for robot grasping. Humans could see, select and pick so much faster. Yet to handle the millions of different everyday items in our factories and warehouses, costly positioning and camera systems have been required.

Extra-small Precision Robot Arm

"Mecademic created an innovative category of industrial robots; one that disrupts what is considered small, compact and precise"

Three Heavily Funded Robotic Arms Projects on Kickstarter

Well over a million dollars pledged for these projects.

Rethinks New Robot: Sawyer

From Rethink:

Introducing Sawyer – the revolutionary new high performance collaborative robot designed to execute machine tending, circuit board testing and other precise tasks that are impractical to automate with industrial robots.

Smaller Footprint, Longer Reach

Smaller and lighter weight than Baxter, and with 7 DOF and a 1026 mm reach, Sawyer can maneuver into the tight spaces and varied alignments of work cells designed for humans.

International Availability

With a base price of $29,000, Sawyer will initially be available in North America, Europe, China and Japan, with limited availability beginning in mid-2015.

Intera 3

Like Baxter, Sawyer is powered by the industry’s best and most intuitive software platform, Intera. It features the same iconic “face” screen (with a refreshed and even more expressive design) that helps it communicate with co-workers, along with the train-by-demonstration user interface that revolutionized how robots can be deployed on factory floors. Sawyer runs on the same version of Intera as Baxter, and will continue to evolve and improve with regular upgrades... (more details) (more about Intera software)

Records 1 to 9 of 9

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.