IMTS 2024 Offers Hidden Technology Gems, New Exhibitors

The International Manufacturing Technology Show offers an opportunity to discover unexpected solutions at more than 1,500 booths, including more than 65 first-time exhibitors offering innovative solutions.

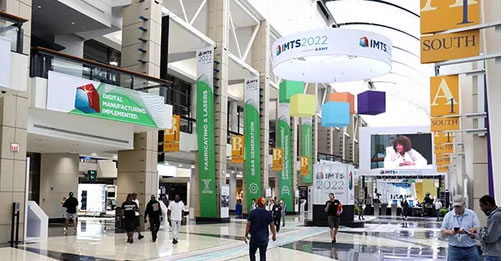

IMTS 2022 Opens Sept. 12, Showcases Digital Tech That Address Manufacturing's Biggest Challenges

Nine technology pavilions feature solutions such as multi-tasking machining centers, robots/cobots, digital twin, manufacturing software, controls, additive manufacturing, and quality control/inspection.

IMTS 2022 Product Preview

IMTS 2022 takes place September 12th - 17th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Universal Robots' New UR20 Collaborative Robot Makes U.S. Debut at IMTS 2022, Expanding Cobot Automation in Machining Industry

Attendees at North America's leading machine tool show will experience how the all-new collaborative, industrial cobot delivers the longest reach and payload in its class, offering the ability to automate even more hard-to-staff tasks in a market struggling to hire.

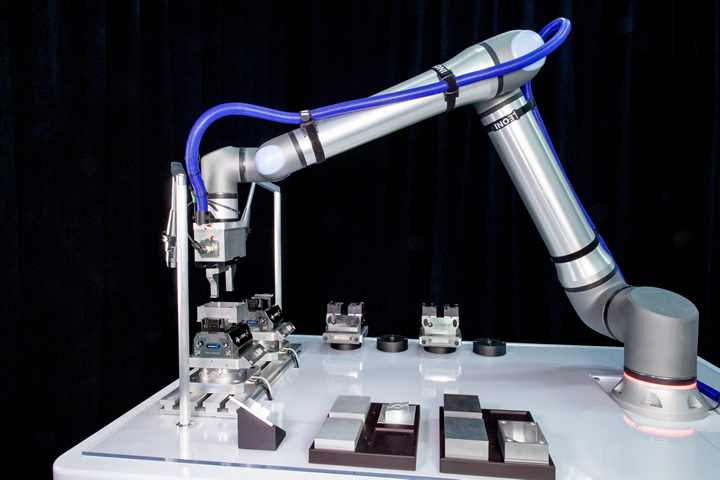

ATI Industrial Automation at IMTS 2022

ATI has pulled out all the stops for our IMTS 2022 exhibit, with our largest booth, largest show staff and most robotic demonstrations ever! In addition, we have a variety of newly-released Force/Torque Sensors, Material Removal Tools, and Robotic Tool Changers

HEIDENHAIN at IMTS 2022

Digital manufacturing starts with HEIDENHAIN. We will be showing software solutions that allows you to model your entire production chain, thus digitalizing your shop floor.

IMTS Spark "Demo Days" Features Interactive Demonstrations, Offers Six Concentrated Learning Opportunities

Inspired by the pavilions at IMTS, which physically group related exhibitors, IMTS Demo Days organizes demonstrations of core manufacturing technologies within a specific time period.

IMTS Connects the Manufacturing Community Through IMTS Network and IMTS spark Digital Destinations

Live events premiere September 14; hosted "coffee chat" previews of IMTS spark scheduled for Sept. 8 and Sept. 9

INTERNATIONAL MANUFACTURING TECHNOLOGY SHOW CANCELLED FOR FIRST TIME SINCE WWII

IMTS to continue to offer digital experiences to foster connections, networking and technical learning opportunities.

RECORD BREAKER: IMTS 2018 LARGEST SHOW EVER

Exponential technology advances, strong economy propel

North Americas premier manufacturing show

Talking IMTS with Universal Robots

IMTS is the North American launch pad for our new flagship line of cobots, the e-Series. With e-Series, we raise the bar for cobots, strengthening the core principles that define collaborative robots: Visit us at Booth #236861 for more.

IMTS 2018 TO BE FIRST SHOW TO FULLY OCCUPY MCCORMICK PLACE

Expanded technology pavilions, co-located shows, conferences, events and two AMTs Emerging Technology Centers; digital connectivity and additive manufacturing among hottest technologies showcased for manufacturers and job shops.

Majority of Exhibitors at North America's Largest Manufacturing Show Pick Universal Robots for Collaborative Robot Applications

With more than 20 exhibitors at IMTS choosing collaborative robot arms from Universal Robots for their show applications, the Danish robotics pioneer will be the number #1 cobot on display

International Manufacturing Technology Show

Smart Manufacturing Hub, North Building, Level 3, Booth 236800 connects with the leading thinkers and doers in the manufacturing industry. The Smart Manufacturing Hub will feature hourly presentations on the most advanced and innovative solutions.

Talking IMTS with Omron

Booth #134845 - OMRONs flexible manufacturing demo will present several solutions designed to help companies meet the customization demands imposed by todays increasingly globalized and eCommerce-driven market.

Records 1 to 15 of 34

Featured Product

For over 25 years, Polyconn has privately labeled and manufactured customized products.

We can produce pneumatic hose and other pneumatic products to match your exact specifications. Our proficient engineering and quality management, coupled with outstanding customer service means Polyconn delivers high quality pneumatic components at competitive prices. Place your order or contact Polyconn for more information on our pneumatic hoses, pneumatic manifolds, Duratec® Pipe or any of our other top quality pneumatic products and components.

.jpg)