Standards, Guidelines & Industry Best Practices for Industrial & Collaborative Robots

The robotics industry is undergoing a significant transformation. There is a need to learn from the past, as multiple times, robots failed to behave as expected because of mechanical failure, power disruption, software issues, and environmental factors.

COBOTS VS COVID: Today's Manufacturing Reality and Tomorrow's New Normal

THIS WHITE PAPER discusses how manufacturers in many industries are leveraging collaborative robots (cobots) to create safe zones for workers returning to production lines.

Cobots Versus Industrial Robots

Buying a new robot is a considerable investment for any business owner. Collaborative robots have been widely marketed as a cheaper alternative to industrial robots, but what's the catch?

Smart Gripper for Small Collaborative Robots

With the growth and proliferation of collaborative robots, there has become an increased need for a wide variety of grippers and end effectors in general. One of the more challenging applications is for automated gauging and measurement of small parts.

What You Need to Know to Work With a Collaborative Robot System

Each of the four types of collaborative robot operation permit varying amounts of interaction between people and robots. Based on the risk assessment, each type will also allow you to remove a portion or all of the safety fencing.

Benefits of Collaborative Robots

It is true that a collaborative robot is designed to work without additional physical guarding like fencing. But the robot is rarely a lone component in a system.

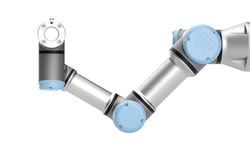

Universal Robots Continues to Dominate Cobot Market but Faces Many Challengers

We identified more than 30 vendors that are currently marketing over 80 cobot models, and we expect this number to grow. More than 80 percent of collaborative robot suppliers generated less than $10m in revenues last year.

Majority of Exhibitors at North America's Largest Manufacturing Show Pick Universal Robots for Collaborative Robot Applications

With more than 20 exhibitors at IMTS choosing collaborative robot arms from Universal Robots for their show applications, the Danish robotics pioneer will be the number #1 cobot on display

Sawyer Goes Mobile for Researchers

With seven degrees of freedom in its arm - and its new mobility platform - Sawyer SDK with Clearpaths Ridgeback platform enables researchers to deploy the robot to a wide range of tasks, providing the flexibility needed to test various projects.

Robotics Advanced Research Alliance - Universities and Corporations

The project -which incorporates machine learning, teleoperation, and human-robot collaboration-- demonstrates what happens when you combine AUBO Robotics' commitment to building symbiotic alliances among researchers and research institutions with robotics specialists

YuMi ®: The World's First Truly Collaborative Dual Arm Robot

Pioneering an inherently safe solution for automating small parts assembly with human coworkers by redefining human-robot collaboration through a unique integration of components, speed, agility and motion control

ABB Robotics hosts over 1,600 guests at its United States Robot Factory opening and Customer Days 2015 events

Auburn Hills, MI becomes the third worldwide manufacturing location for ABB robots; Customer Days featured over 55 live robotic demos and 53 technical training seminars

ABB launches YuMi and acquires gomTec

ABB leapt into the collaborative robotics space at the Hannover Messe trade show by launching their two-armed YuMi robot and simultaneously announcing their acquisition of German startup gomTec

Records 1 to 13 of 13

Featured Product

BitFlow Introduces 6th Generation Camera Link Frame Grabber: The Axion

BitFlow has offered a Camera Link frame grabbers for almost 15 years. This latest offering, our 6th generation combines the power of CoaXPress with the requirements of Camera Link 2.0. Enabling a single or two camera system to operate at up to 850 MB/S per camera, the Axion-CL family is the best choice for CL frame grabber. Like the Cyton-CXP frame grabber, the Axion-CL leverages features such as the new StreamSync system, a highly optimized DMA engine, and expanded I/O capabilities that provide unprecedented flexibility in routing. There are two options available; Axion 1xE & Axion 2xE.

The Axion 1xE is compatible with one base, medium, full or 80-bit camera offering PoCL, Power over Camera Link, on both connectors. The Axion 2xE is compatible with two base, medium, full or 80-bit cameras offering PoCL on both connectors for both cameras.

The Axion-CL is a culmination of the continuous improvements and updates BitFlow has made to Camera Link frame grabbers.

.png)