Headquartered in Solon, Ohio, HDT Global is widely recognized as the world leader in the design and manufacture of many products in use by U.S. and allied military units, civilian governments, and commercial customers today.

Dr. Tom Van Doren | HDT Robotics

Please tell us a bit about your company and how you are involved in the robotics industry.

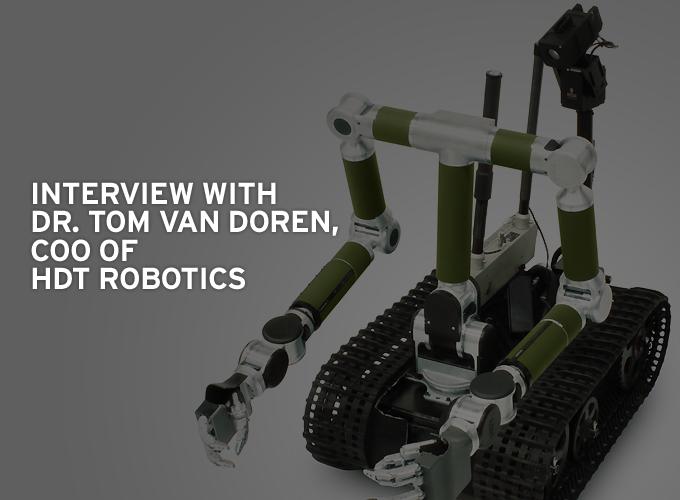

HDT Robotics is a division of HDT Global. We develop cutting edge robotic manipulation products, military logistics robots and intelligent assist devices.

Please explain the underlying technology of the robot.

Our Adroit™ series of manipulator arms are dexterous, compact, high-load and light-weight systems. The underlying technology was originally developed on the DARPA Revolutionizing Prosthetics program for a radical new prosthetic arm, and HDT has continued development to provide robotic manipulator arms with near-human strength, dexterity and size.

What is distinctive about the MK2 compared to the MK1?

The Adroit™ MK2 arm is a comprehensive upgrade to the MK1 variant. The Adroit™ MK2 is completely environmentally sealed, has higher load capacity and is more rugged than the MK1, while maintaining the same light weight and high dexterity.

The original MK1

The new MK2

What is distinctive about the MK2 compared to other robots?

The weight of an Adroit™ arm system is at least 70% lower than that of competitors’ arms of similar load capacity. The speed of the joints in an Adroit™ arm is typically three times faster, and the arms have at least two times as many actuated degrees of freedom when compared to conventional arms.

Our end effectors have three fingers with an opposable thumb and can grasp and use many of the same tools that a human can (e.g., cordless drills, saws, etc.). The high number of degrees of freedom in the arm means that the end effector is more easily positioned than on typical arms, allowing many more tasks to be performed remotely.

In addition to the high dexterity and load capacity, every joint on the Adroit™ arm systems has a torque sensor and absolute position sensor. This sensorization allows sophisticated control techniques to be implemented, including force control that allows the arms to operate in the same workspace as humans.

What is new or upcoming from HDT in this arena?

Retrofit kits to mount Adroit™ arms to QinetiQ TALON and iRobot Packbot robots are available now from our reseller A-T Solutions. Retrofit kits for other robots will be available soon.

In addition to the Adroit™ arm systems, HDT Robotics will soon introduce our Protector series of logistics and trail clearance robots. The Protector is diesel- or JP8-powered, can carry up to 1,000 pounds and has over three days of operating endurance with on-board fuel.

What are some military and civilian applications of the MK2?

The Adroit™ MK2 arm system was developed to be used anywhere that remote projection of human dexterity is desirable. This includes material handling, law enforcement and military applications. Military applications include explosive ordnance disposal and route clearance.

Please explain general market information about the MK2 (i.e., potential purchasers/users, price point, etc.)

Customers in the military or in law enforcement interested in Adroit™ MK2 arm retrofit kits can contact A-T Solutions at sales@a-tsolutions.com for pricing and availability. All other customers please contact HDT at robotics@hdtglobal.com.

Aside from the military, what other markets are opening up for you robotics applications?

We are pursuing health care and commercial applications and will have additional product announcements over the next year.

About HDT Global

About HDT Global

Headquartered in Solon, Ohio, HDT Global is widely recognized as the world leader in the design and manufacture of many products in use by U.S. and allied military units, civilian governments, and commercial customers today.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product