It will be worth your time to analyze each segment of your business and decide if automation is right for your business and if automation can produce more efficiency or profit.

Len Calderone | RoboticsTomorrow

"The factory of the future will have only two employees, a man and a dog. The man will be there to feed the dog. The dog will be there to keep the man from touching the equipment." ~Warren G. Bennis

Automation means increased efficiencies in business. As more businesses automate their processes, they become more proficient and profitable. Business process automation is the strategy a business uses to automate methods in order to contain costs. It consists of integrating applications, restructuring labor resources and using software applications throughout the organization.

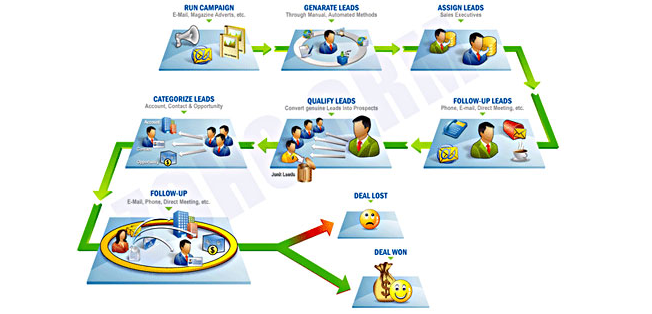

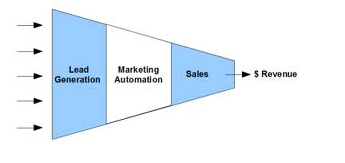

One of the most important functions of any business is sales and marketing. The more that automation is used in this business segment, the faster a company can respond to inquiries, and the faster product can be turned. In the case of a service company, fast response means satisfied customers. If a customer is looking for service, that customer wants service now not in days or even weeks. Your company has to be in a position to respond quickly.

Using a marketing automation tool will ease the workload on the marketing department. It will spend less time manually gathering information and setting up workflows. Instead the department will be able to spend more time generating demand for the business.

In order to effectively aid marketers in fully understanding customers and subsequently developing a strategic marketing plan, marketing automation tools (MAT) are designed to perform key tasks. The first is to analyze marketing campaigns and prospects. This will help the marketing team manage the marketing campaigns. Then, the customer data is stored and organized.

Using a MAT, a company can see if a web site is generating a demand for a product or service. Does a potential customer just look, or do they buy? Do they buy, ask for more information or just leave the site? By analyzing this information, a company can determine if the proper message is getting to the prospect to entice the shopper to make a purchase. If the analysis shows many customers visiting the product or service area of the company’s web site, but do not buy, it might mean the message is not resonating.

We are all trying to get the attention of our potential customers. The great promise of MAT is that it enables a company to generate messages based on a web visitor’s actions. Instead of spam, which is usually segregated when delivered to a prospect’s mail box, a custom message becomes more relevant. The information in a company’s marketing automation campaign must match the expressed interests of that potential customer. If the prospect shows an interest in a particular product or service, the company must stay on that topic in its responses, and not promote another product or service unless the shopper shows an interest.

Automation software enables marketing departments to measure what works and what doesn’t work. MAT demonstrates the impact on revenue, and when integrated with existing sales force automation systems, it becomes a true collaborator with the sales department.

LeadFormix is a highly proactive, cloud based, B2B Marketing Automation platform that helps identify and create sales opportunities by measuring visitor intent. LeadFormix utilizes MAT to help companies align marketing and sales functions and derive maximum ROI for their marketing efforts. Their marketing automation goes beyond demand generation and workflow automation by providing insight into a website visitor's intent, deriving actionable intelligence to convert a visitor into a qualified lead.

Silverpop, another marketing automation company, automates the process of sending a company’s marketing communications. Instead of a manual process that's time-consuming and subject to human error, Silverpop enables a company to create sophisticated and engaging campaigns that automatically respond to a prospect’s behaviors, lifecycle segments and other criteria.

HubSpot, Inc. offers an all-in-one marketing software platform that has helped more than 5000 companies in 34 countries attract leads and convert them into customers. Applications in the software platform include website management, blogging, search engine optimization, lead management, marketing analytics, email marketing, landing pages, and social media monitoring. HubSpot is also the developer of the popular website analysis tool, WebsiteGrader.com, which has more than 3 million users.

Several of the other leading MAT companies are Aprimo Inc., Genius.com, Loopfuse, Marketo Inc, Neolane, Net-Results, Pardot, and SalesFusion.

Every business has repetitive tasks that run every day to enable a business to operate. By automating these processes a company can lower costs, reduce risk and keep a high level on management of the entire operation.

Other automation software provides vital information to sales and service representatives allowing them to inquire into inventory status, pricing, credit, purchasing, and account history. There are segments of manufacturing and distribution that need important functions automated, such as unit-of-measure conversion, material processing, tag control, and inventory tracking. Automated inventory programs reduce accounts receivable and inventory investment, raise productivity, and much more.

One of the important missions for automation is workflow management. Such a system defines and manages a series of tasks to produce a final outcome, even if the jobs are different. In a manufacturing environment, a design document might be automatically routed from the designer to the technical director to the production department with a check on uncompleted tasks. A workflow management system can also convert documents from one format to another, depending on the process; and the system can follow the requirement for the completion of each task.

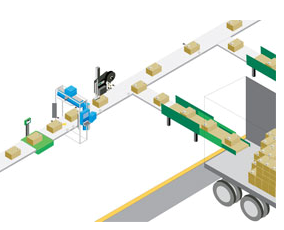

Organizations often implement improved inventory picking techniques, new order picking equipment or new processes in an attempt to gain productivity in their operations. This entire operation can be automated to speed the picking process, while avoiding errors. As product is delivered to the warehouse, the order is entered into the company’s computer system, which locates an empty location and assigns that location to the newly arrived product. When a customer places an order, the computer locates all of the items on the order and prints out a pick list or sends the information to a tablet in the possession of a picker. The pick list tells the picker the location where each item is, starting from the area furtherest from the packing and shipping area. As the picker pulls each item, he or she moves closer to the packaging area, thereby saving time, as the picker does not have to retrace his/her steps to fill the order. This type of automation can be used in any inventory situation, whether it is manufacturing parts or distribution inventory.

Using an automated man-on-board picker, the picker is usually on a rail on the floor. The picker can travel along the rail delivery system down aisles in a storage facility through manual or automatic operation. The worker in the picker can direct the system to take him to the product location required, and lift the worker to the appropriate shelving height.

Many U.S. manufacturing companies are deciding to keep manufacturing at home by automating, and in some cases, bringing back manufacturing that had previously been sent overseas. The growing interest in automation outside of the automotive industry is due to robotic innovation in areas, such as metalworking, semiconductor, electronics, photonics, spot welding, arc welding, assembly, coating and dispensing and material handling.

Scalable robots are used for automated packing of boxes, while palletizing & de-palletizing robots automate the loading and unloading of pallets. Robots pick up things, carry them and put them where they are supposed to go.

Material handling equipment integrators help a company reach production goals by coordinating separate material handling elements into a smoothly functioning, unified whole. Whether you are handling cases, totes, bottles, bags, drums, pallets, or any of an infinite variety of manufactured or processed goods automated material handling is a must. Automated conveyors allow the input of boxes in one area of the warehouse, and either through hard coded rules or data input allows destination selection. The box will later appear at the selected destination.

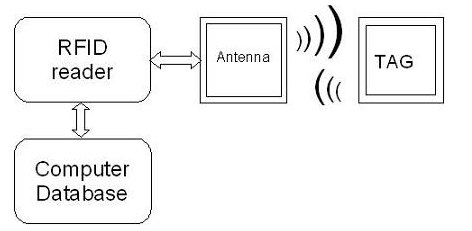

RFID systems collect accurate and real-time data and communicate it via radio waves. A typical RFID system has three components, tags, reader and RF unit. The RF reader sends out RF waves that are received by the RF tag within the reader's range. The tag in turn, sends information back to the reader. Then the RF reader transfers this information to a RF unit.

RFID technology finds its applications in various commercial sectors, such as inventory management, and access control for buildings. Conventional tracking systems require manual counts, which is labor intensive, time consuming, and error-prone. On the other hand, the use of RFID technology has significant advantages over the conventional methods.

In a replenishment-based system, whenever the inventory at a warehouse or distribution center drops below a certain level, a replacement order is instituted. RFID-tagged products will allow warehouses to track the location and count of inventories in real time.

In order to save costs associated with getting products out the door, shippers are focusing on solutions that reduce the amount of time handling the product. High performance, reliable bar code sorting equipment is an integral part of this effort, as this equipment increases efficiency and improves cost savings.

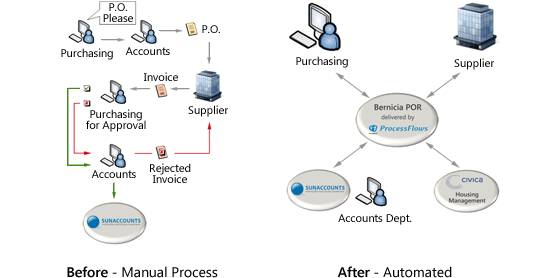

(Courtesy of ProcessFlows.co.uk)

Once the order is out the door, an invoice must be initiated. Automated invoicing occurs without the need to prepare a manual invoice. Invoicing systems of this type provide the ability to generate and send electronic copies to customers. The invoice can also be printed, along with an envelope immediately after the invoice generation, or printed at a specific time of day. Some automated systems will fold the invoice, insert it in an envelope and lick the envelope. Okay, not quite lick it.

Some invoicing programs can be integrated with the order entry. When the order is complete, the system generates an invoice based on input as to what is packaged.

(Courtesy of gps-tracking-truck.com)

If a company uses its own trucks for deliveries, a GPS tracking program is essential. Advanced tracking technology is improving businesses, as customers start expecting more when it comes to fast deliveries and on-time service. With a GPS tracking system, you can accurately predict arrival times for improved customer service, control scheduling, manage driver accountability, track down time, and even find stolen vehicles.

Automation in business is multifaceted, beginning at the front office to the production floor, to the warehouse and finally shipping. Automation saves money, time and man power, if properly implemented. Utilizing an experienced integrator is important to make all of the components come together for a seamless operation.

Business strategy itself will be automated. By automating the connection between the company’s strategy and individual team objectives, the software alerts employees of these changes, leaving no room for doubt as to how a change in strategy impacts their priorities, objectives, and whatever performance metrics they will be measured against.

It will be worth your time to analyze each segment of your business and decide if automation is right for your business and if automation can produce more efficiency or profit.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

TM Robotics - Shibaura Machine THE SCARA range

The THE range from Shibaura Machine is an extensive line up of SCARA robots. Available in four arm lengths THE400 (400mm), THE600 (600mm) and the most recent THE800 (800mm) and THE1000 (1000mm), this range is suitable for assembly, handling, inspection and pick and place processes in varied industrial applications. The THE1000 boasts a 20kg payload capacity and an impressive 0.44 second cycle time, providing high speeds for processes with large components. In fact, the range has been recognised for as the price-to-performance leader compared to other SCARA models in its price range due to its impressive speed versus payload capacity.