Exceptional image quality, including the ability to transport this high-bandwidth video in real time, is absolutely essential to protecting our war fighters, as well as civilians who may be in harms way.

John Procacci | IMT

Tell us a little bit about IMT?

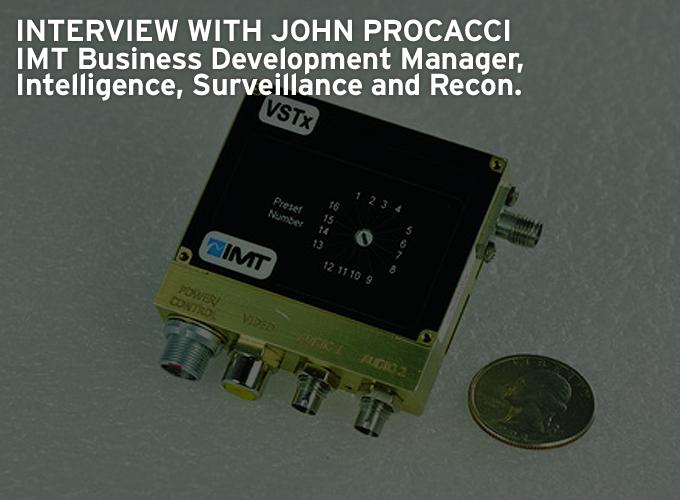

IMT's military, aerospace and government group specializes in innovative digital microwave video solutions for defense, security and law-enforcement applications. IMT’s product portfolio includes portable and ultra-compact transmitters and receivers; COFDM microwave links; digital, portable and fixed airborne video systems and specialty antennas. These video transmission products provide enhanced situational-awareness capabilities in mission-critical environments such as covert surveillance, tactical-systems monitoring and strategic detection. Headquartered in New Jersey, IMT’s state-of-the-art manufacturing facility features a complete production process, from research and development to engineering design, manufacturing, testing, integration and technical support. IMT’s solid reputation as a quality leader and trusted provider of video applications has landed the company numerous delivery orders with state and local police departments, NASA, the Department of Justice, several Air Force bases and large defense contractors. IMT is an ISO 9001:2008-certified QMS organization and the recipient of multiple industry awards for design and innovation.

What types of features or requirements do the military have that make it different from other video surveillance equipment?

The military is focused on protecting and supporting the war fighter with rugged, capable and proven technologies.

First and foremost, the product must meet the specific technical specifications, such as small size, weight and power (SWaP); high mean time between failure (MTBF) and, most importantly, reliable link performance. In order to optimize reliability, certain mission specifications we have seen from the military require tougher than usual environmental conditions. These include extended temperature, humidity, drop, shock and vibration testing, etc. In addition, some military applications have specified special waveforms, interoperability and/or EMS/EMI standards. Any major risks are addressed well before any product is integrated into an active platform.

Second, in today’s environment the ability to meet specifications must be balanced with a cost-effective solution. Gone are the days of ‘technology at any cost.’

And finally, the military is looking for open-architecture functionality to avoid being locked into one system, product or supplier due to proprietary technology. All of these features must be available in a solution that is quickly deployed, easy to operate, upgrade and swap, as the technology and requirements evolve. IMT has invested in the appropriate quality-assurance personnel and environmental test equipment and chambers on site to ensure compliance and reliability. Having more than 20 years of fielding reliable products has enabled us to save the military redundant qualification costs, since in many cases we can qualify some of our products by denoting prior similarities.

With regards to video radios, another extremely important factor besides reliability is maximizing the video range the user has from danger. IMT’s compact radio solutions incorporate COFDM, diversity reception and maximal ratio combining. These technologies ensure superior range to keep the war fighters out of harm’s way in both line-of-sight and especially in non-line-of-sight environments, where multipath fading crops up.

With the existing UAVs and other unmanned vehicles currently available is it difficult to change the technology on them like upgrading the video with a newer camera? Are most UAVs built to allow for modular upgrades?

Smart suppliers work very hard to offer military-grade products that can be easily integrated into their platforms to lessen the schedule and cost impact of switching to another product or technology. The military spends a lot of time and effort to qualify a particular product or solution, but having a second source is critical to mitigating future risks associated with potential supplier issues. An open-architecture, fully modular solution is becoming more common with military requirements, with the primary purpose of mitigating risks—allowing immediate access to life-saving products without the risk of production delays.

Changing weight, shapes, payloads, etc., can affect a UAV’s drag and avionics, among other features. Changing cameras normally has a positive impact, as sensors are constantly improving. However, that is the perfect time to look at upgrading the video radio solution as well, which is also improving over time. IMT has extremely compact solutions that are much lighter and more capable then some legacy units out there, and they use less power. Unlike other radio companies, we can customize end-to-end solutions that can upgrade the UAV’s video radio range, performance and real-time image-distribution options. IMT offers two- to 12-way multiple-diversity receive solutions to choose from, along with hand-held mobile viewing displays with Ethernet outputs and interference-spectrum viewers that can stream video as well. Our sister company, Haigh-Farr, also offers conformal, blade and button antennas to help upgrade the UAV’s video range.

How important is video quality for UAVs?

The difference between disaster and mission-success can be the result of poor picture quality when attempting to decide on whether to pull the trigger or not. UAVs can operate from an altitude of hundreds to tens of thousands of feet, and the value UAVs bring is the visual information they provide. Exceptional image quality, including the ability to transport this high-bandwidth video in real time, is absolutely essential to protecting our war fighters, as well as civilians who may be in harm’s way.

It is important to note that video is only one piece of the video radio’s mission. Nowadays, adding new sensors on the unmanned vehicles is becoming increasingly important. Users want to include metadata and information from other sensors, such as chemical/Hazmat/nuclear-radiation detectors, GPS etc., without adding extra radios. IMT’s video radios have a built-in user-data backchannel that can transport video and audio, plus take the RS232 data from the UAV to the receiver at up to 115KBd.

What do you think is next for video technology inside unmanned vehicles? Extreme light sensitivity, higher frame rates?

Having the ability to ‘see’ in poor conditions is an important aspect for any system. Operating in the dark, in sand storms, in highly populated areas, etc., are common elements of today’s war environment and improving this aspect of any system is crucial. Advancements in camera technology must be balanced with advancements in the transport mechanism (i.e., the data link) to be able to supply increasingly high-resolution video content to the decision makers who may be located in a mobile command center on the ground, or possibly across the world. Improved picture quality is useless if it never reaches those that require this information to make wise decisions.

In the future, do you think we will be more limited by the cameras or by the bandwidth required to reliably broadcast and receive the signals?

I believe both sides of the equation will continue to be pressured by SWaP requirements as platforms become smaller and more capable. Smaller sizes mean less weight, which means less power to operate, which means longer flight times or less stress on our soldiers to carry systems, which in essence provides a force multiplier effect by helping our soldiers and operators to be more efficient. Suppliers are constantly battling the realities of physics with more creative approaches, and each component of the overall system will push other contributors to maintain even higher levels of performance. In addition, expanding out beyond the traditional data link will be the requirement to operate on different networks (i.e., cellular networks, military data links, etc.) to adapt to changing conditions anywhere our soldiers find themselves in conflict.

To address the bandwidth issue, IMT has developed very narrowband channel spacing and user software that can maximize video throughput in bandwidth-starved environments. We also have the ability to build products that can take four SD signals and mux them over one HD channel, with the user being able to switch back to the HD if needed. The new hybrid COFDM 3G/4G video radio that IMT is currently working on represents another solution we have in our portfolio to help. In addition, we presently offer dual/multiband units and we can provide COFDM drop cams. The drop cams can help save bandwidth in certain unmanned-system missions. Typically, UGVs use two radios: one is a high-data-rate video link and the other is a low-cost, low-data-rate telemetry link to control the robot. The drop cam can save bandwidth since it does not need the telemetry link. It can be dropped off by a robot exactly in place without taking any telemetry bandwidth from other mission assets needing that band.

About IMT

About IMT

IMT is a leader in advanced digital microwave video systems serving the MAG (Military, Aerospace & Government) market. IMT is located in a refurbished 65,000-square-foot engineering and manufacturing facility in the International Trade Center in Mt. Olive, NJ. IMT has ISO 9001:2008 QMS certification.

IMT's Military, Aerospace and Government products group specializes in innovative digital microwave solutions for defense, security and law enforcement applications. These video transmission products provide enhanced situational awareness capabilities in mission critical environments such as, covert surveillance, tactical systems monitoring and strategic detection.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

ElectroCraft's Motion Control for Mobile Robots

ElectroCraft is showcasing its award-winning mobile robot technology including their powerful and compact wheel drives, high-torque-density brushless DC motors, precision linear actuators as well as servo motor drive technology at a variety of conferences and tradeshows including the Boston Robotics Summit. Robotics Summit is the premier symposium for the sharing of ideas, technology, and market developments for robotic technologies across industries. Beyond a showcase and pitch of product, ElectroCraft is eager to participate in the collaborative discussion of challenges and opportunities that will shape the near and long-term robotic marketplace.