Consumer robotics is the next big frontier. Military, academic, and industrial robotics are thriving segments due to an abundance of financial resources and clear cut cost benefits in costs, safety and efficiency. Small businesses will start to have access to technology that was only available to larger enterprises (e.g. manufacturing, warehousing robots).

Michael Walker | Bossa Nova Robotics

Tell me your entrepreneurial story. What attracted you to robotics?

Robots are inevitable. All of our technological advances will eventually manifest in robotics or cyborg technology. I grew up loving Asimov and Sci Fi and always imagined a future where our lives would be improved through meaningful relationships with intelligent robots. As CMO for the company, I see an unprecedented opportunity to be at the forefront of an emerging category that will change the lives of consumers and shape the way our society embraces and interacts with robots.

What was the inspiration for Bossa Nova Robotics?

BNR was initially a spin off from Carnegie Mellon's Robotics Institute in Pittsburgh PA. Our founder, Dr. Sarjoun Skaff, worked on projects for NASA and DARPA and saw an opportunity to delight children with the locomotive technology that he had developed. He started BNR as a toy company in 2005 and since then we have developed keen insights into making emotional connections with consumers through machines. In 2012 we took those insights and shifted our focus to personal robotics with a mission to build a 21st century version of Rosey Jetson for everyday consumers.

Could you tell us a little about Bossa Nova's Robotic Cloud Services?

Our Robotic Cloud Service (RCS) was developed as a critical part of our play experience for the Mechatars brand of interactive robots. The technology allows thousands of robots to exchange information, dynamically update their software, and customize themselves to individual consumers. RCS offers the promise of helping to reduce cost and improve experiences by shifting computing processes from the robots to the cloud servers. The potential benefits of cloud based robotics is still unfolding and we will be a leader in that space.

Where there specific hurdles you encountered while building robots (i.e. issues in mechanical developments, getting specific parts of the prototype to work, etc.)?

The toy business is notoriously tight on price points and margins while maintaining high expectations on quality and feature performance for electronic toys. One of the competitive advantages we developed as a robotics toy company is the ability to significantly reduce the cost through creative engineering, manufacturing and supply chain. Our engineers and Asian operations teams worked with new materials, developed smart tooling and manufacturing strategies as well as contemporary product development processes and techniques. For example, integrating a 3D printer onsite with the engineering team allows rapid prototyping at a fraction of the cost and time that traditional process would prescribe.

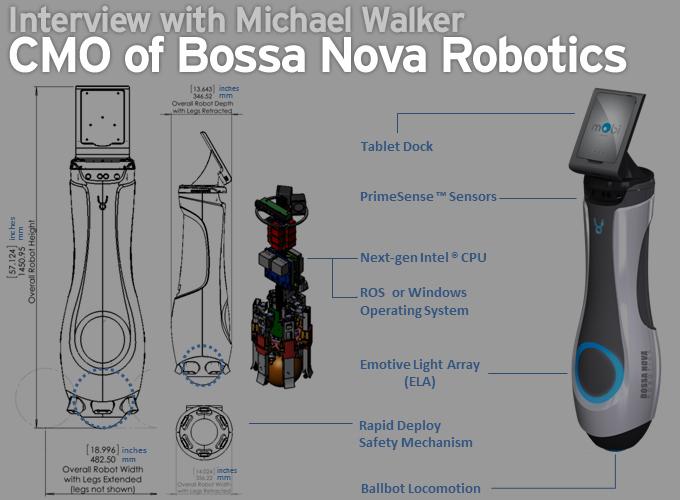

As our first shift away from toys to serious robotics, our latest prototype, mObi, presented additional challenges. mObi will be the first commercially available ballbot platform for researchers and developers. The robot dynamically balances on a ball, providing a single point of contact that enables elegant motion and slender human environment friendly designs. As we approached the reveal date, the team had 2 months to figure out how to develop a safety mechanism in the event that the robot tipped over or powered down suddenly. Conventional wisdom among academics at the time suggested there was no way to do this. However, we were able to tap into our relationship with the CMU Robotics institute and found a researcher (who was not aware that it was impossible) and, working together with our engineers and their rapid prototyping capabilities, the team was able to rapidly iterate on several potential solutions until we found one that worked. The right team, the right tools, and the right pressure.

In the near future what industries do you think are the most likely to benefit from the recent advancements in robotics?

Consumer robotics is the next big frontier. Military, academic, and industrial robotics are thriving segments due to an abundance of financial resources and clear cut benefits in costs, safety and efficiency. Small businesses will start to have access to technology that was only available to larger enterprises (e.g. manufacturing, warehousing robots). For consumers, Robotics are already a greater part of our lives than we know. Our appliances are smarter. Our cars are smarter. Our TVs, cell phones, and toys are smarter. There are really just a few small degrees between what we generally think a robot is and what these smart machines are already capable of.

What about beyond industrial needs? How many years do you think we are away from having multipurpose robots inside the home? What needs to happen before we reach that point?

I think we will see big advances in "consumer machines" we already use (appliances, electronic) as well as the deployment of personal robots within the next 5 years. Three things need to happen to accelerate this: component and manufacturing costs need to continue to decline, AI and HRI (human robot interaction) technology needs to continue advancing and our (American) culture needs to become more comfortable with the idea of robots in our personal space. Asian countries like Japan and Korea are light years ahead of us in terms of cultural acceptance of a robotic future. Unfortunately, American pop culture has nurtured suspicion and fear of potential Skynet and Terminator scenarios. We will have to overcome that with real world experiences and smart- approachable design principles for personal robots

What can you tell us about the emotional attachment humans feel with hardware, including personal robots? How do designers and engineers incorporate the emotional factor into building robots and why is this important?

We are emotional creatures. We love technology and machines and we want the things we love to love us back. This is why people give names to their Roombas and put eyelashes on their VW Beetles. This is also why we are so intrigued with Siri or the TiVo character. It’s a chance to interact with the tech we love. The principle idea of a robot, from a consumer perspective, is that the smart machine can be perceived as an intelligent being. Even if devoid of emotion, like Pinocchio or Data from Star Trek, we all know that deep inside those CPU's, that robot wants to have emotions and feelings and wants to love us back.

Designers and engineers can capitalize on this by taking lessons from the toy industry. A well designed teddy bear can deliver and emotional engagement that eclipses any experience delivered by the most sophisticated social robot and do it for a fraction of the cost. The key is not to be so fascinated by the engineering and technology that you lose sight of the emotional triggers and cues that enable consumers to believe what they want to believe. Siri doesn't have feelings and isn't truly "intelligent" or sentient, but she does provide enough humor, surprise and utility for us to suspend belief, for just a moment, and imagine that we have a genie in our hands.

Where do you see Bossa Nova in the next 5 to 10 years

Our mission is to build a 21st century version of Rosey Jetson for consumers. Its' a terrific metaphor that's easy to visualize and to imagine the benefits of having her as a member of any modern household. Within 5 years, we will have delivered a significant first step by offering a premium personal robot for consumer households that will help to stimulate an entirely new industry. Within 10 years, we will see a significant upgrade in the robot's capabilities as well as lower priced mass market options that will put more personal robots into more homes. The robots are coming and we are going to love them. BNR wants to be part of that new frontier.

About Bossa Nova Robotics

About Bossa Nova Robotics

Our vision is bold: Put a Personal Robot in Every Home

We started that process 2005 as a spin off from The Robotics Institute at Carnegie Mellon University and since then we’ve sold almost 500,000 toy robots built on technology derived from those labs. In 2011 we built our proprietary Robot Cloud Services, designed to take on heavy computational processing and deliver new content to the robot.

Based on number of units sold we are leading provider of cloud-connected robotics products. It is our experience manufacturing toys that will enable us to deliver on the promise of companion robots with the personality of Rosey Jetson and a price point that is comparable to today’s new technology.

About Michael Walker, Chief Marketing Officer

Michael J. Walker is a passionate and creative multi-channel marketer with a knack for building brands in new categories or repositioning them for growth within existing ones. His marketing experience spans multiple channels from, B2B, B2C, and International and he has also held significant roles in Sales, Business Development and Corporate Strategy. At Bossa Nova, Michael leads the development of the company's brand architecture and go-to market strategies for their robotics platforms across academic, B2B2C and direct to consumer verticals.

Prior to joining BNR, Michael was the Global Marketing Leader for The Sims portfolio at Electronic Arts where he was responsible for all aspects of the global marketing mix. He was a senior marketer at Mattel where he successfully lead the global repositioning of the Hot Wheels franchise to enhance its relevance and for developing a ground breaking strategic alliance with Warner Bros. Michael established his classical marketing experience with 12 years of brand management at Kraft Foods after receiving his MBA from the University of Michigan.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product