ABB Robotics has introduced the IRB 6700 robot family, its seventh generation of industry-leading, large industrial robots.

L Hetherington for | RoboticsTomorrow

Original press release:

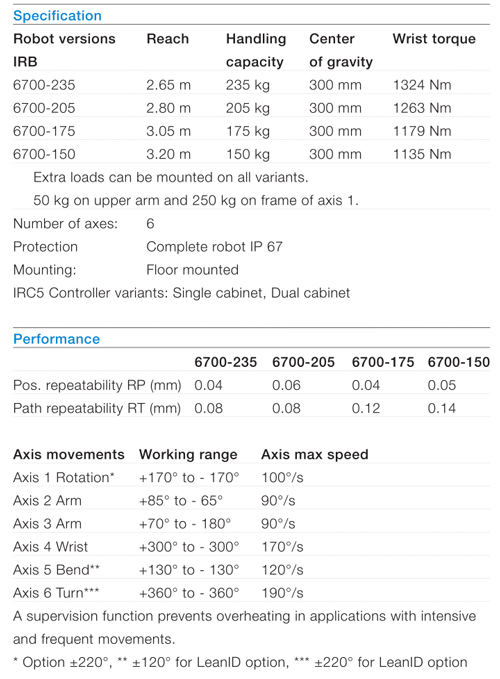

ABB Robotics has introduced the IRB 6700 robot family, its seventh generation of industry-leading, large industrial robots. The new IRB 6700 is available in payloads from 150 to 300 kg, and reaches from 2.6 to 3.2 meters, and is designed for spot welding, material handling and machine tending. In addition to enhanced speed, payload and accuracy, the power consumption has been lowered by 15%, total cost of ownership has been reduced by up to 20%, and maintenance has been optimized, doubling the time between service intervals.

...

“Our aim from the beginning was to deliver a robot with the lowest total cost of ownership available,” says Ola Svanström, ABB Robotics product manager for large robots. “When we asked our customers what they value most in our large robots their answer was virtually unanimous - reliability. So, we revisited every aspect of our current range to improve everything we could in this regard. It may not look that different from its predecessor on the outside, but the hundreds of small improvements on the inside are what count.”

...

Service routines for the machine have been shortened and intervals between them have been increased. Access to motors has also been improved and technical documentation for maintenance has become easier to read and understand through the use of improved graphics and 3D simulations called "Simstructions." ... (full press release)

Key Differentiators

- Lowest TCO (Total cost of ownership)

-

Lean ID on all variants

- Long and predictable life time of dress packs - Significantly reduced downtime because of reduced maintenance

-

Outstanding reliability

- Design focused on high uptime and fault free operation – Arm designed for MTBF of 400,000 hours

-

Stronger

- 150kg payload at 3.2m reach

- 300kg payload at 2.7m reach

-

Sustainable

- 15 percent lower power consumption

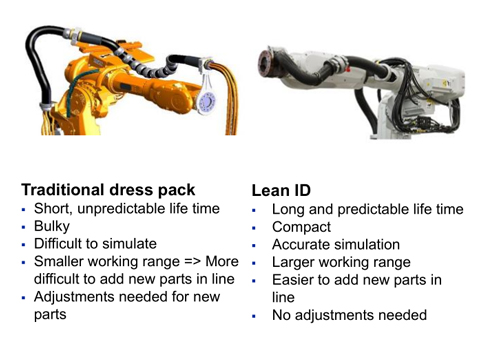

Lean ID

Every robot in the 6700 family has been designed to accommodate Lean ID—a new Integrated Dressing (ID) solution meant to achieve a balance between cost and durability by integrating the most exposed parts of the dress pack into the robot. Equipping an IRB 6700 with Lean ID makes it easier to program and simulate with predictable cable movements, creates a more compact footprint, and lengthens service intervals due to lessened wear and tear.

Data Sheets

Additional links:

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product