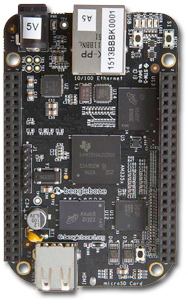

The BeagleBone Black is the latest low cost single-board computer in the BeagleBoard family.

L Hetherington for

The BeagleBone Black is the latest low cost single-board computer in the BeagleBoard family.

The specs are as follows:

| PRICE | $45 MSRP |

| CPU | 1 GHz ARM Cortex-A8, VFPv3 Lite + NEON, 256 KB L2-Cache |

| GPU | PowerVR SGX530 |

| Memory | 512 MB DDR3 |

| USB 2.0 ports | USB 2.0 type A host port. Dedicated single mini-USB 2.0 client port (no additional 2-port hub) |

| Video | microHDMI |

| Audio | microHDMI |

| Onboard storage | 2 GB 8-bit embedded MMC on-board flash version, microSD card 3.3 V Supported |

| Onboard network | 10/100 RJ45 |

| Low-level peripherals | 4x UART, 8x PWM, LCD, GPMC, MMC1, 2x SPI, 2x I²C, A/D Converter, 2xCAN Bus, 4 Timers |

| Power ratings | 210-460 mA @5 V Depending On Activity and Processor Speed |

| Size | 3.402 in × 2.098 in |

| Weight | 39.68 g (1.400 oz) |

Like Arduino Shields the BeagleBone Black hardware can be expanded with Capes:

Not all Beagleboard Capes are fully compatible with the BeagleBone Black. A complete list of capes and compatibilty can be found here.

Compatible Software:

- Ubuntu

- Rowboat (Enables Android for Texas Instruments devices)

- Bonescript (A node.js library for BeagleBone)

- A full list of registered projects can be found here.

If you are having trouble deciding between the BeagleBone Black or Raspberry Pi Michael Leonard has a great breakdown here.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product